Method for preparing washable core mold used for preparing hollow workpiece by using RTM molding technology

A core mold, hollow technology, applied in the field of composite RTM molding and preparation, to achieve the effects of convenient use, high fiber volume content, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

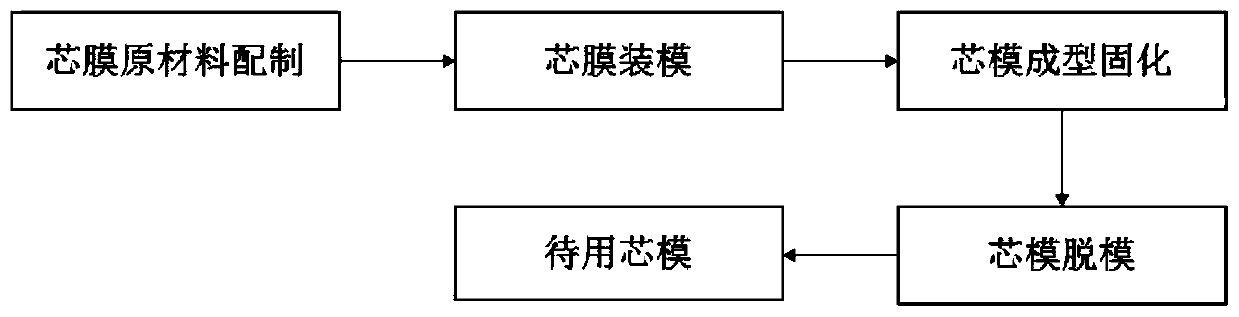

[0040] 1) Prepare sodium bicarbonate, polyethylene glycol, and polyvinylpyrrolidone aqueous solution: respectively weigh 5 grams of sodium bicarbonate, 12 grams of polyethylene glycol, and 5 grams of polyvinylpyrrolidone into 100 ml of water in sequence, and stir to dissolve;

[0041] 2) Wash the quartz sand three times with water, place it in an oven at 80°C, and dry it;

[0042] 3) Take 1,000 grams of the solution in 1) and 1,000 grams of dried quartz sand in 2), stir well and moisten evenly, and set aside;

[0043] 4) Add the uniformly mixed quartz mortar in 3 to the mandrel mold several times, and compact it repeatedly each time;

[0044] 5) Add the assembled mandrel mold into the oven, set the temperature at 160°C for 4 hours, and the mandrel is formed;

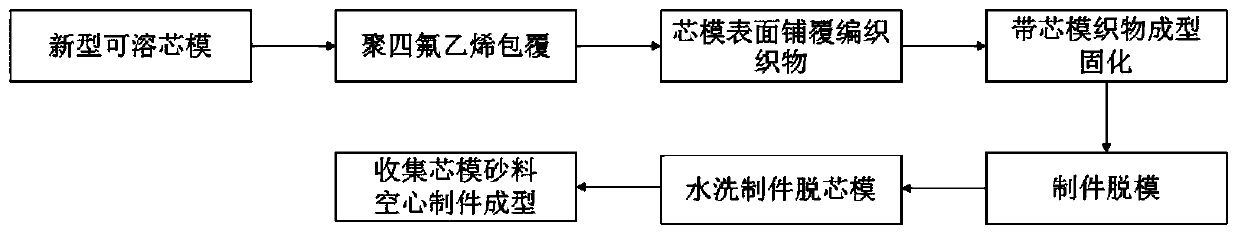

[0045] 6) After the mandrel is cooled, take out the mandrel, polish both ends, and cover with a high-temperature-resistant polytetrafluoroethylene sealing film with glue;

[0046] 7) Spread the fabric on the surface of...

Embodiment 2

[0049] 1) Preparation of aqueous solutions of polyethylene glycol and polyvinylpyrrolidone: Weigh 18 grams of polyethylene glycol and 6 grams of polyvinylpyrrolidone respectively, add them to 120 ml of water in turn, and stir to dissolve;

[0050] 2) Wash the quartz sand three times with water, place it in an oven at 80°C, and dry it;

[0051] 3) Take 1,000 grams of the solution in 1) and 1,000 grams of dried quartz sand in 2), stir well and moisten evenly, and set aside;

[0052] 4) Add the uniformly mixed quartz mortar in 3 to the mandrel mold several times, and compact it repeatedly each time;

[0053] 5) Add the assembled mandrel mold into the oven, set the temperature at 170°C for 5 hours, and the mandrel is formed;

[0054] 6) After the mandrel is cooled, take out the mandrel, polish both ends, and cover with a high-temperature-resistant polytetrafluoroethylene sealing film with glue;

[0055] 7) Spread the fabric on the surface of the mandrel in 6), and then install t...

Embodiment 3

[0058] 1) Preparation of polyethylene glycol and polyvinylpyrrolidone aqueous solutions: respectively weigh 20 grams of polyethylene glycol and 10 grams of polyvinylpyrrolidone into 200 ml of water in turn, stir to dissolve;

[0059] 2) Wash the quartz sand three times with water, place it in an oven at 80°C, and dry it;

[0060] 3) Take 1,000 grams of the solution in 1) and 1,000 grams of dried quartz sand in 2), stir well and moisten evenly, and set aside;

[0061] 4) Add the uniformly mixed quartz mortar in 3 to the mandrel mold several times, and compact it repeatedly each time;

[0062] 5) Add the assembled mandrel mold into the oven, set the temperature at 160°C for 4 hours, and the mandrel is formed;

[0063] 6) After the mandrel is cooled, take out the mandrel, polish both ends, and cover with a high-temperature-resistant polytetrafluoroethylene sealing film with glue;

[0064] 7) Spread the fabric on the surface of the mandrel in 6), and then install the mold, injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com