Preparation method and equipment of high-strength and high-fiber-volume-content resin-based composite material

A composite material and volume content technology, which is applied in the field of resin-based composite materials, can solve the problems of low shear strength of the part layer, white spots on the product, and insufficient penetration, etc., to achieve increased fiber volume content, high fluidity, Avoid the effect of white spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

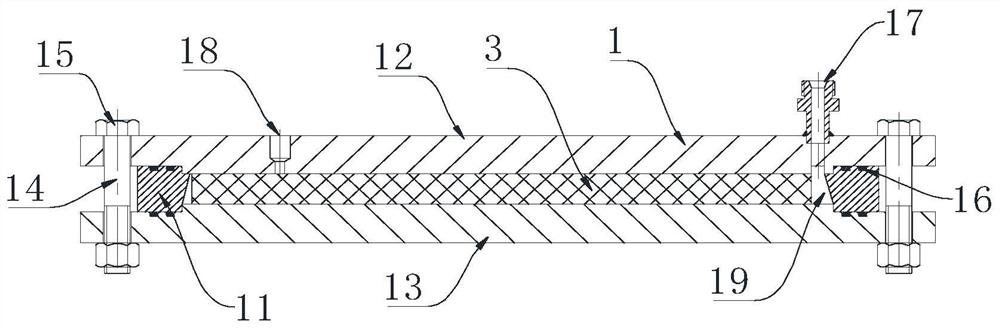

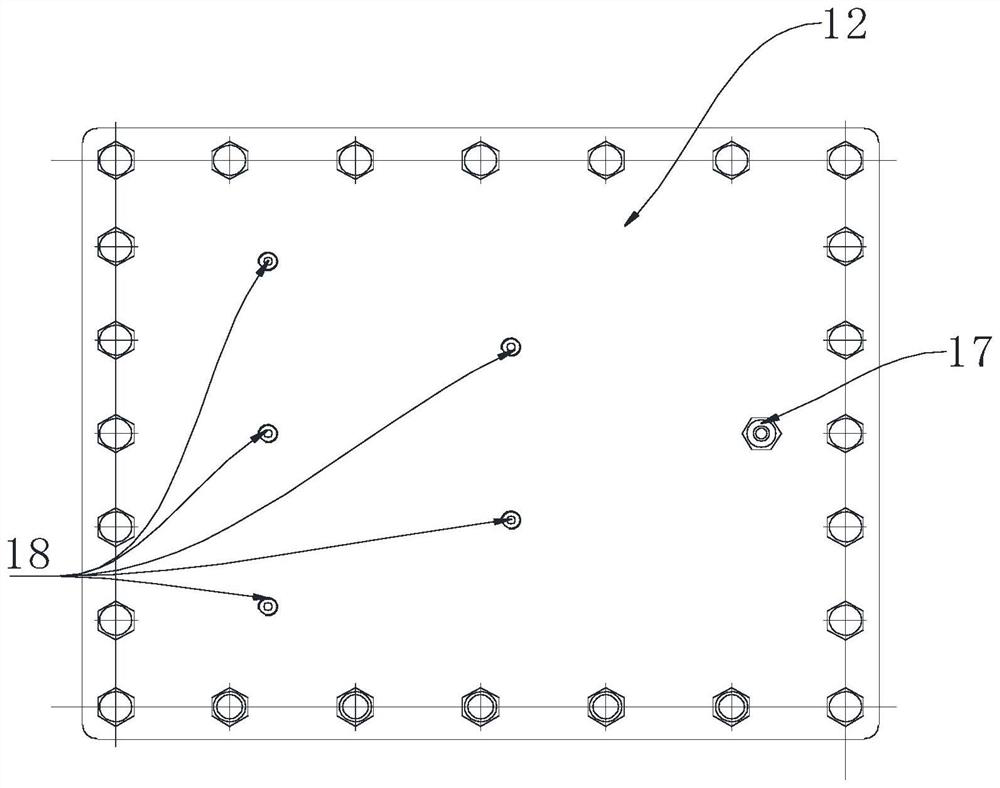

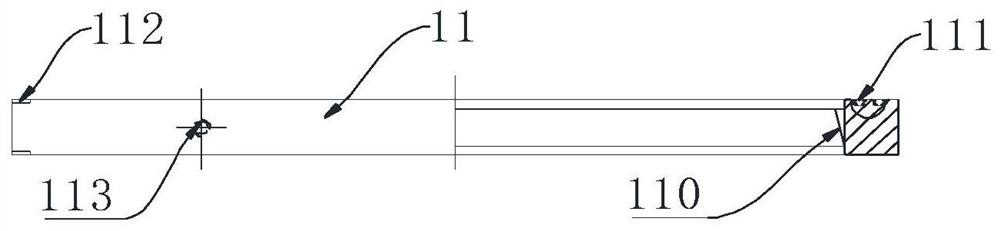

Embodiment 1

[0047] (1) The minimum effective length and width of the mold cavity is 391mm×291mm, the mold cavity height is 20mm, the cut fabric size is 390mm×290mm, the fabric (type B quartz fiber cloth) specification: 0.28mm thick, surface density: 291.32g / cm 2 , 80 layers of fabric. (2) After layering, the fabric is pre-pressed to be 2 mm higher than the thickness of the mold cavity, and then shaped. (3) The laminated fabric is stitched with a needle-punching stitching mechanism, and the stitching distance is 10mm×10mm. (4) The final pressure of the mold, using the upper and lower surfaces of the mold to further press the pre-pressed fabric that is 2mm higher than the thickness of the mold cavity, so that the thickness of the fabric and the mold cavity are equal. (5) The molding process, the application of reactor pressure and the control of the vacuum degree in the mold cavity during the molding process are carried out alternately. Preheat the reaction kettle, mold, and metal hose be...

Embodiment 2

[0049] (1) The minimum effective length and width of the mold cavity is 391mm×291mm, the height of the mold cavity is 20mm, the cut fabric size is 389mm×289mm, the fabric (type B quartz fiber cloth) specification: 0.28mm thick, surface density: 291.32g / cm 2 , 80 layers of fabric. (2) After layering, the fabric is pre-pressed to be 3mm higher than the thickness of the mold cavity, and then shaped. (3) The laminated fabric is stitched with a needle-punching stitching mechanism, and the stitching distance is 10mm×10mm. (4) The final pressure of the mold, using the upper and lower surfaces of the mold to further press the pre-pressed fabric that is 3mm higher than the thickness of the mold cavity, so that the thickness of the fabric and the mold cavity are equal. (5) The molding process, the application of reactor pressure and the control of the vacuum degree in the mold cavity during the molding process are carried out alternately. Preheat the reaction kettle, mold, and metal h...

Embodiment 3

[0051] (1) The minimum effective length and width of the mold cavity is 391mm×291mm, the height of the mold cavity is 20, the cut fabric size is 390×290, the fabric (type B quartz fiber cloth) specification: 0.28mm thick, surface density: 291.32g / cm 2 , 80 layers of fabric. (2) After layering, the fabric is pre-pressed to be 1 mm higher than the thickness of the mold cavity, and then shaped. (3) The laminated fabric is stitched with a needle-punching stitching mechanism, and the stitching distance is 10mm×10mm. (4) The final pressure of the mold, using the upper and lower surfaces of the mold to further press the pre-pressed fabric that is 1mm higher than the thickness of the mold cavity, so that the thickness of the fabric and the mold cavity are equal to fill the cavity. (5) The molding process, the application of reactor pressure and the control of the vacuum degree in the mold cavity during the molding process are carried out alternately. Preheat the reaction kettle, mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com