Semi-active-type suspended vibration isolating device for driving cab

A semi-active, driver's cab technology, applied in transportation and packaging, upper structure, upper structure of trucks, etc., can solve the problems of high manufacturing cost and complex structure, and achieve low manufacturing cost, good vibration reduction effect, Create a convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

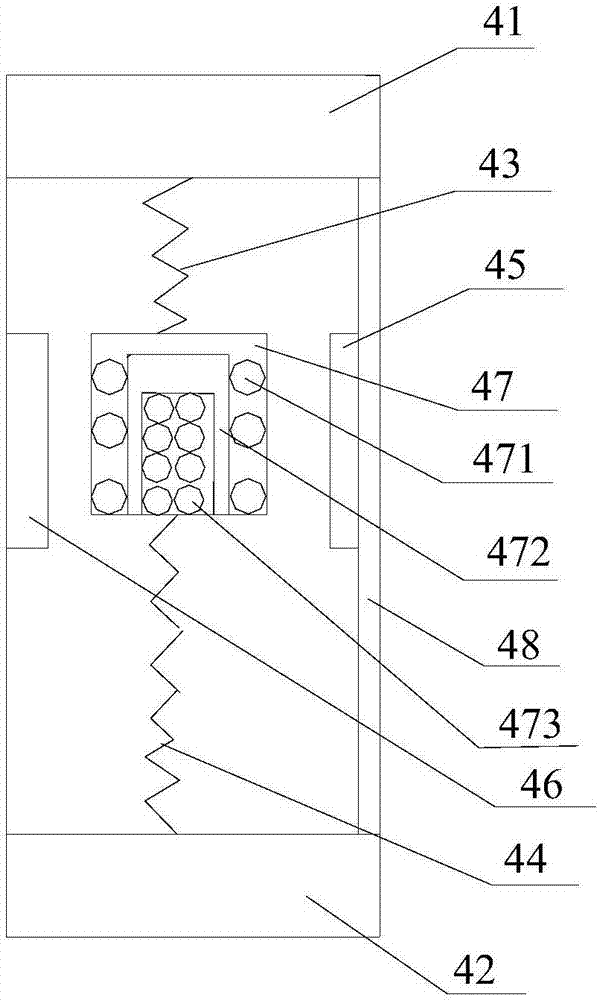

[0036] In this embodiment, the housing 47 is preferably a cuboid, and the dimension parameters of the cuboid's length, width and height are preferably 400*300*380 mm, and the hollow copper rods 471 are arranged symmetrically along the inner wall of the housing 47 at heights of 100 mm, 200 mm, and 300 mm. 3, a total of 6, the diameter of the hollow copper rod 471 is preferably 20 mm, the fourth electromagnetic particle damper 474 filled inside the hollow copper rod 471 is spherical particles, and the average diameter of the spherical particles is preferably 5 mm , the material is preferably steel; the hollow inner casing 472 is preferably a cuboid, and the dimension parameters of the cuboid's length, width and height are preferably 200*300*100mm, and the material of the hollow inner casing 472 is preferably rubber material, the The third electromagnetic particle damper 473 filled in the hollow inner shell 472 is spherical particles, the average diameter of the spherical particle...

Embodiment 2

[0040] This embodiment only explains the parts different from Embodiment 1;

[0041] In this embodiment, the hollow inner casing 472 is preferably a cuboid, and the dimension parameters of the cuboid's length, width and height are preferably 200*300*100mm. The material of the hollow inner casing 472 is preferably rubber material, and the hollow inner casing The third electromagnetic particle damper 473 filled in 472 is a spherical particle, the average diameter of the spherical particle is preferably 2mm, the material is preferably steel, and the total volume of the third electromagnetic particle damper 473 is 90% of the volume of the inner shell 472 %;

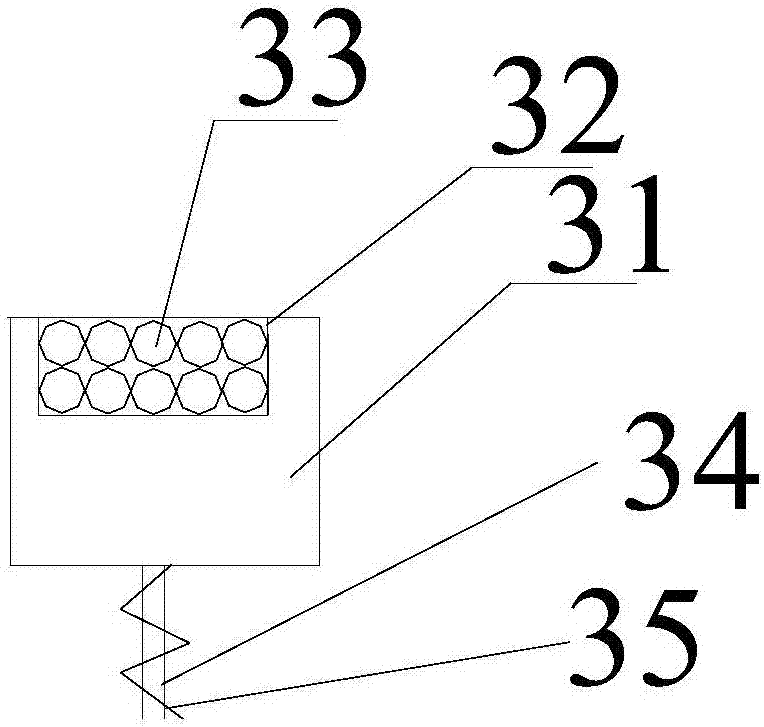

[0042] The control housing 31 is preferably a cuboid, and the size parameters of the length, width and height of the cuboid are preferably 700*400*300 mm, and the inner control housing 32 is preferably a cuboid, and the size parameters of the length, width and height of the cuboid are preferably 600*350 mm. *200mm, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com