Automatic polaroid storing device for polaroid cleaning

A polarizer, automatic technology, applied in the field of cleaning machinery, can solve the problems of inconsistent vector printing position, poor user experience, insufficient quantity, etc., to achieve the effect of improving satisfaction, quality assurance, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

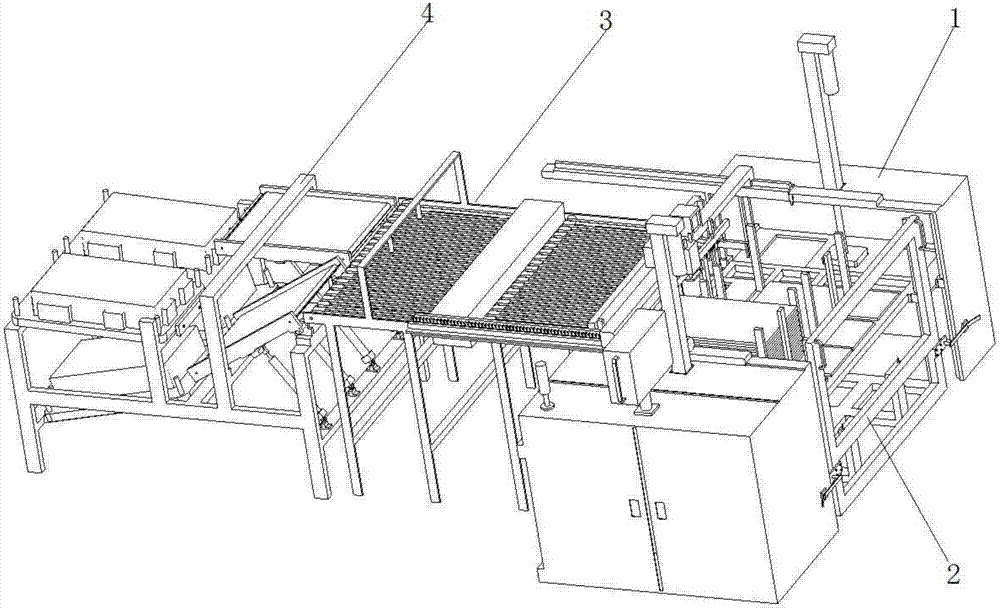

[0023] refer to figure 1 The shown automatic polarizer cleaning device includes a mechanical console 1 , a moving trolley 2 , a polarizer cleaning machine 3 and a film receiving device 4 .

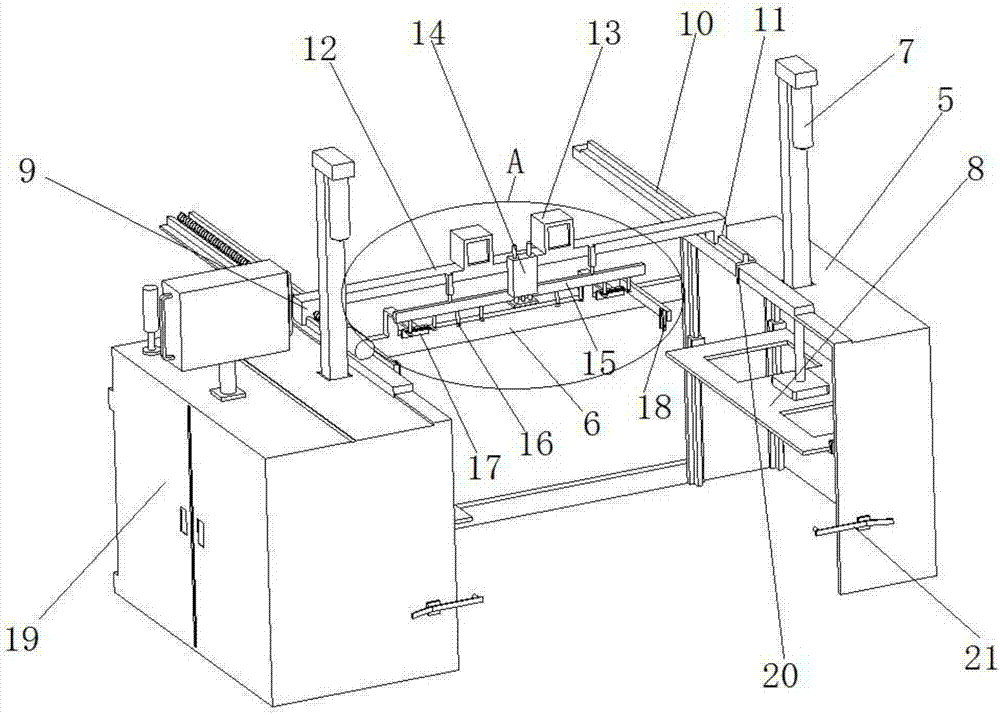

[0024] refer to figure 2 As shown, an electrical control cabinet 19 is provided on one side of the mechanical console 1, and the mechanical console 1 includes two symmetrically arranged racks 5, and the two racks 5 are connected by cross beams 6 to accommodate mobile In the U-shaped area of the trolley 2, the first lifting platform 8 driven by the lifting motor 7 is arranged on the two frames 5 . The frame 5 is provided with a positioning pin 21 for fixing the mobile trolley 2 , and the mobile trolley 2 is correspondingly provided with a plug plate 23 matching with the positioning pin 21 .

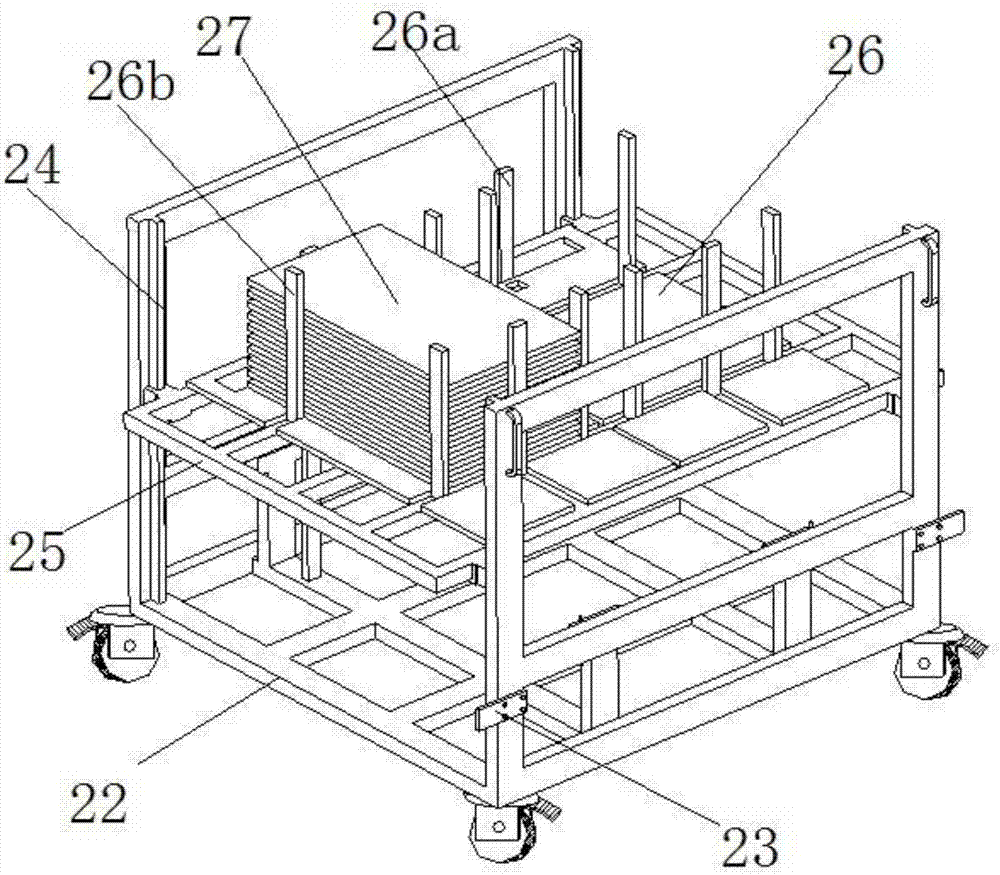

[0025] refer to image 3 As shown, the mobile cart 2 includes a car body 22, and the car ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com