Circulation cooling type micro-coring drill bit

A technology for circulating cooling and coring drill bits, which is applied to drill bits, drilling equipment, earthwork drilling and mining, etc. It can solve the problems of high mechanical load, large thermal load, difficulty in forming micro-cores, and high labor intensity of drill bits, so as to improve core quality. quality, avoid crushing and re-crushing, improve integrity and core yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

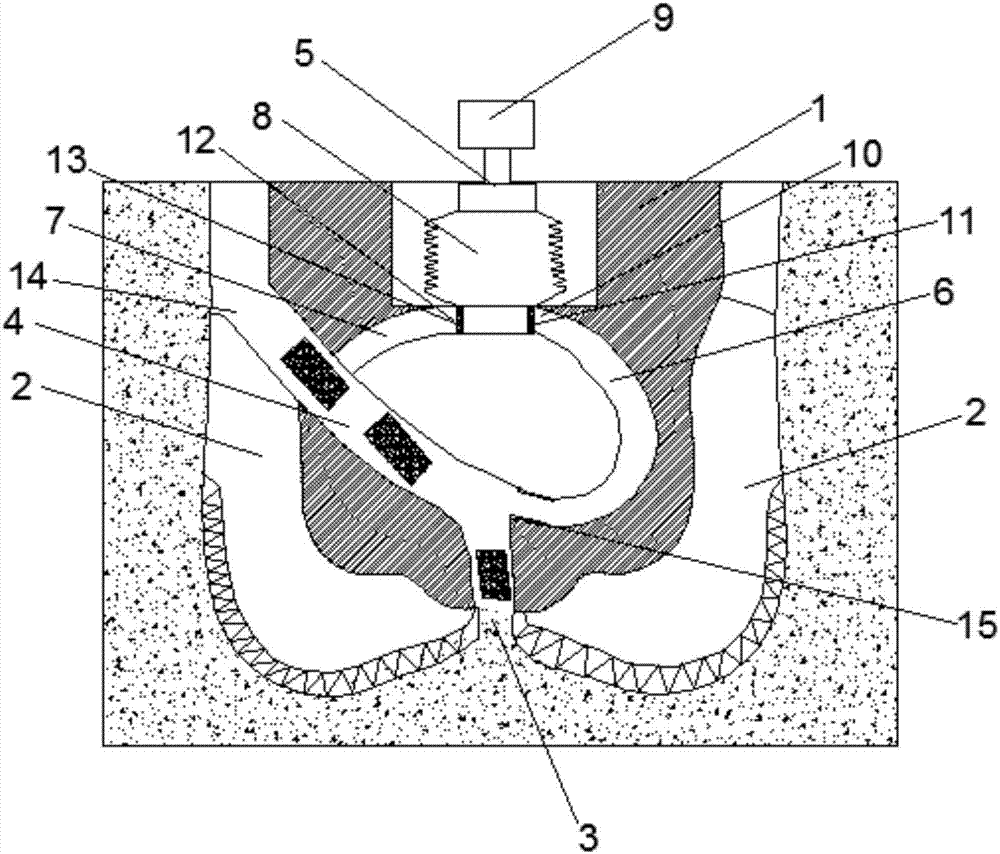

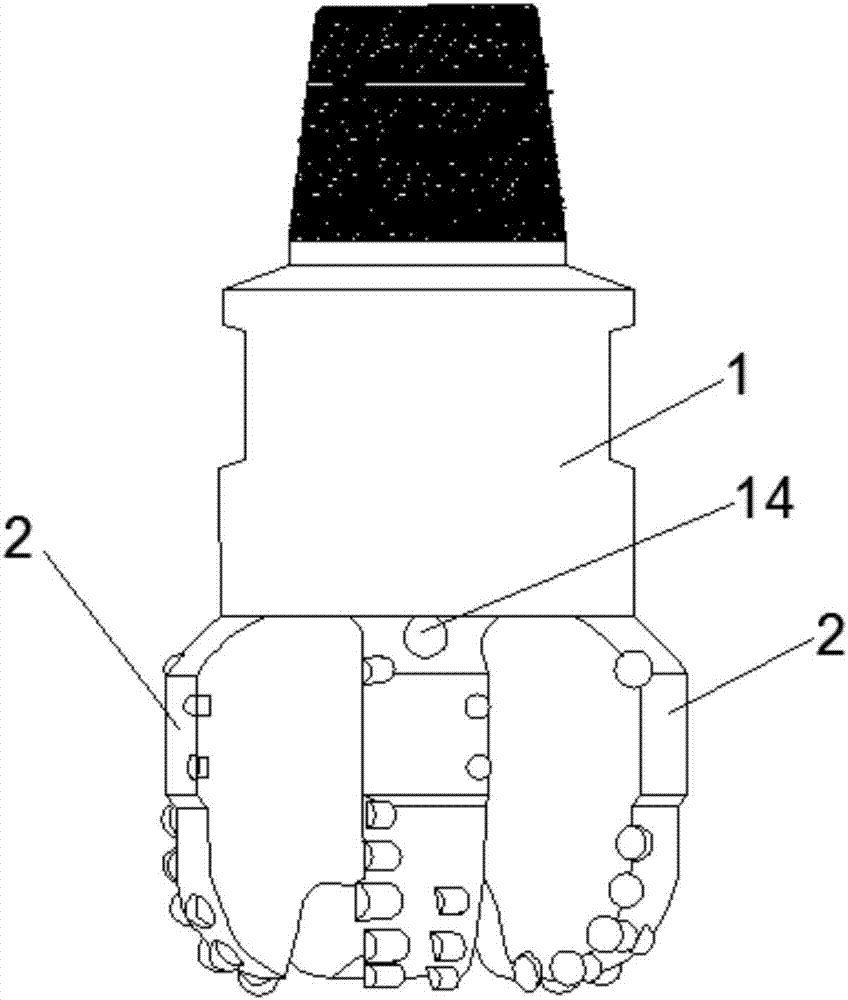

[0028] Such as figure 1 and figure 2As shown, the present embodiment provides a circulating cooling type micro core drill, comprising a drill body 1 and a blade 2 arranged on the drill body 1, a core hole 3 is provided in the middle of the bottom end of the drill body 1, and a core hole 3 is provided in the drill body 1. The top of the core hole 3 is provided with at least one coring passage 4 communicated with the coring hole 3, the lower end of the coring passage 4 communicates with the coring hole 3, and the port at the upper end of the coring passage 4 is a core outlet 14, and the coring The channel 4 has the same diameter as the coring hole 3, which is 13-23mm; the drill bit body 1 is also provided with a circulating cooling channel and a cooling device 5 communicating with the coring channel 4, specifically, the circulating cooling channel includes an output channel 6 and a pumping The suction channel 7 and the cooling device 5 include a stretching cylinder 8 and a hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com