A coal mining and transporting machine integrating cutting and raking coal mining

A technology for mining, transporting and raking coal, applied in cutting machinery, slitting machinery, earth-moving drilling and other directions, can solve the problems of difficult advancement, low quality of coal products, large gangue content, etc. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

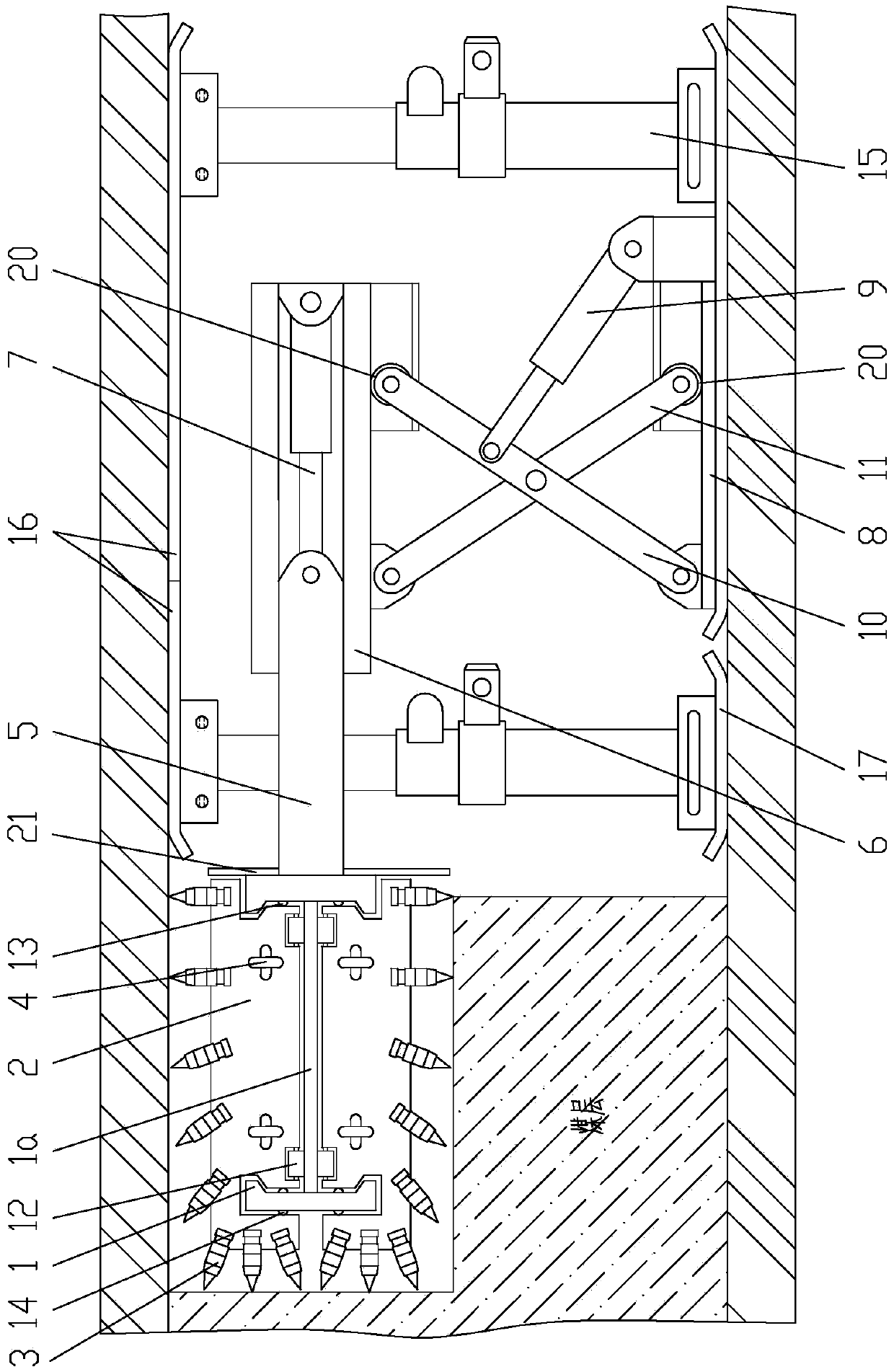

[0016] see figure 1 , a coal mining and transporting machine integrating cutting and raking coal mining, which is composed of a coal mining and transporting main frame and a support; The coal cutting tooth 3 on the conveying chain plate 2 constitutes an integrated structure of mining and transportation; the conveying chain plate 2 has an overhang section protruding from the front wall of the frame 1, and the overhang section extends toward the frame 1 along the height of the frame 1 Extending in the direction of the barrier 1a, part of the conveyor chain plate 2 is provided with at least one coal cutting tooth 3, and the coal cutting tooth 3 is also distributed on the extension section, and several consecutive conveyor chains equipped with coal cutting teeth 3 The plates 2 constitute o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com