Efficient heat exchange pipe, heat exchanger with heat exchange pipe and air conditioner

A heat exchange tube and heat exchanger technology, which is applied in the fields of high-efficiency heat exchange tubes and heat exchangers and air conditioners with the heat exchange tubes, can solve the problem of reducing blasting strength, reducing the energy efficiency ratio of air conditioners, and reducing the flow rate of small U-bends and other problems, to achieve the effect of improving heat exchange efficiency, realizing energy saving and environmental protection, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

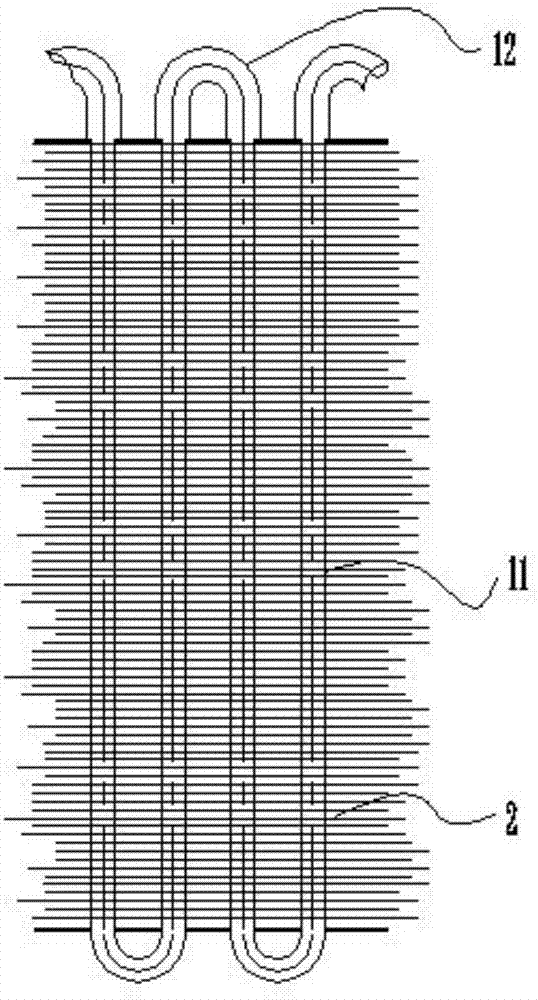

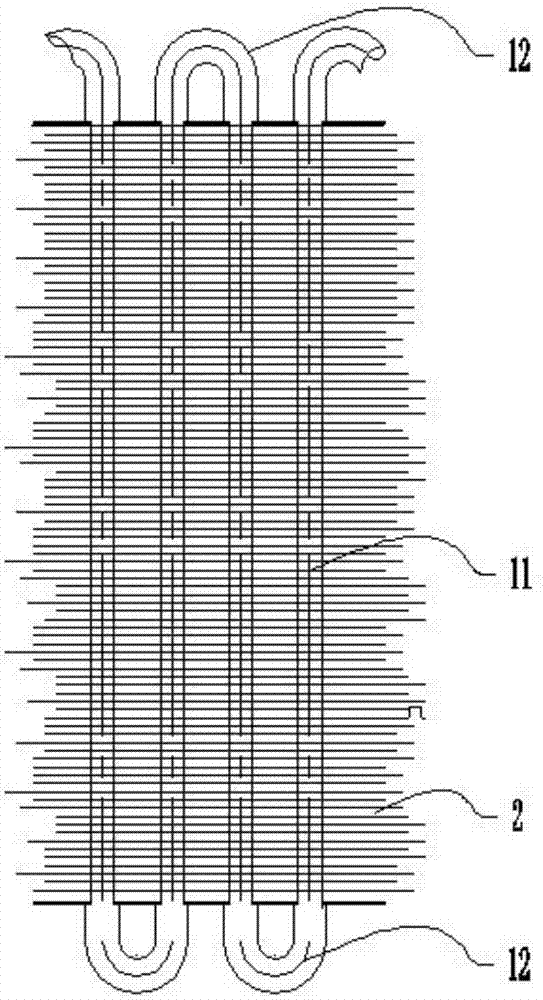

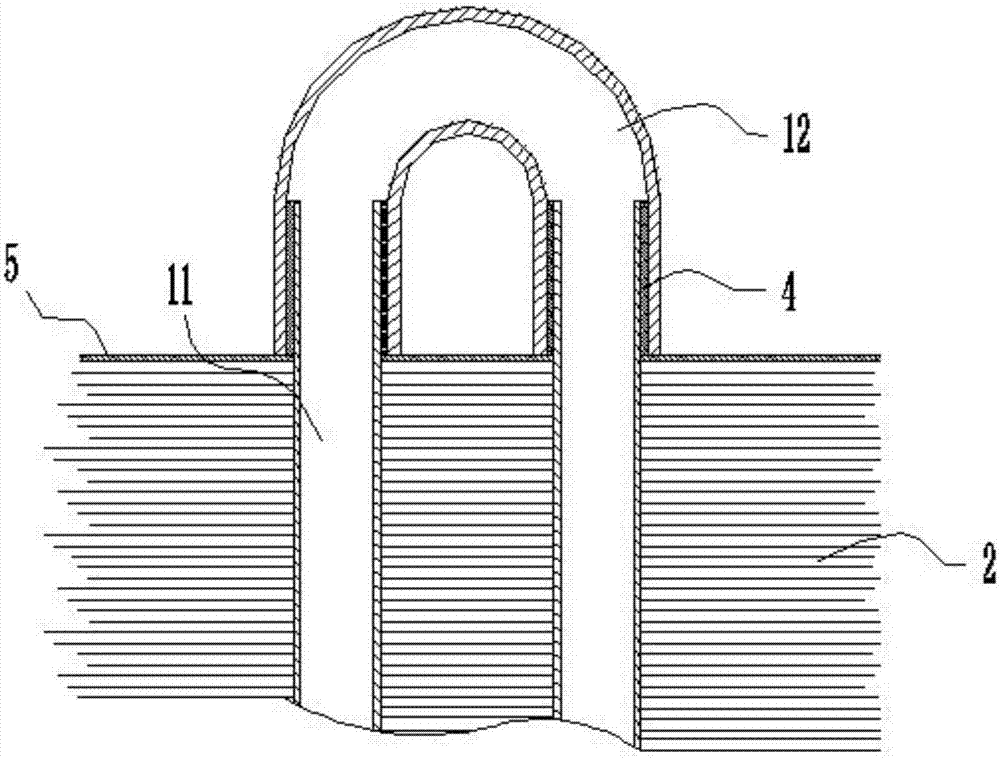

[0054] A heat exchange tube, such as Figure 16-21 As shown, the difference between this embodiment and the embodiment is that the heat exchange tube in this embodiment is not a round tube but a flat tube body; the equivalent diameter of the inner diameter of a single hole of the tube body is less than 7mm; when the tube body is not When there is a partition, its equivalent diameter is less than 7mm, preferably less than 5mm; when there is a partition in the pipe body, the pipe body will be divided into multiple passages, and the single hole refers to the passage here; because the pipe body is small , so that the distance between the tubes can be reduced, so that the efficiency of the fins is improved, the effective area of heat transfer is increased, the flow resistance when the air flows through is reduced, the heat exchange efficiency is improved, and the work efficiency is high.

[0055] Such as Figure 4 , 6 As shown, a heat exchanger, the heat exchanger includes a he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Equivalent diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap