Coal mine tunnel roof stress online monitoring system based on fiber grating sensor and method thereof

A fiber grating and stress monitoring technology, applied in the field of monitoring systems, can solve the problems of difficult coordination of fiber grating bolt strain, inaccurate fiber grating measurement results, fiber grating damage, etc., and achieves good electromagnetic interference resistance, convenient installation, and use. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

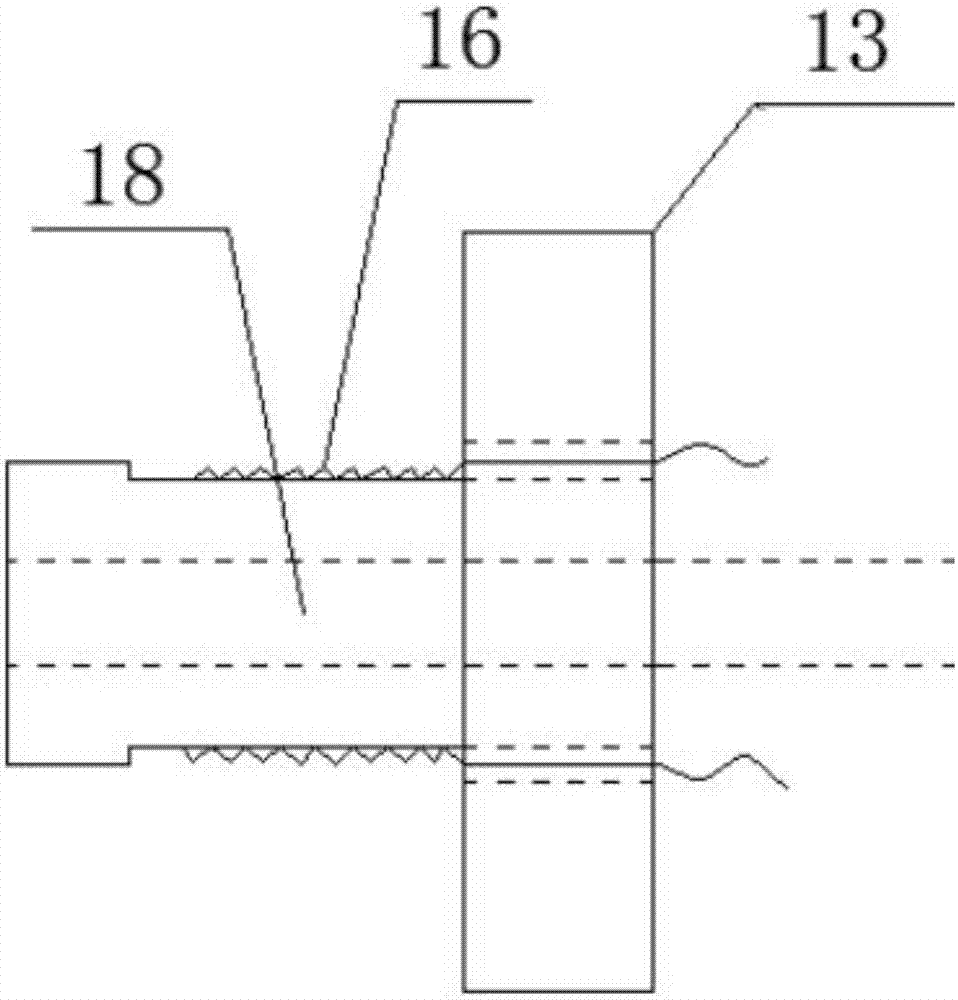

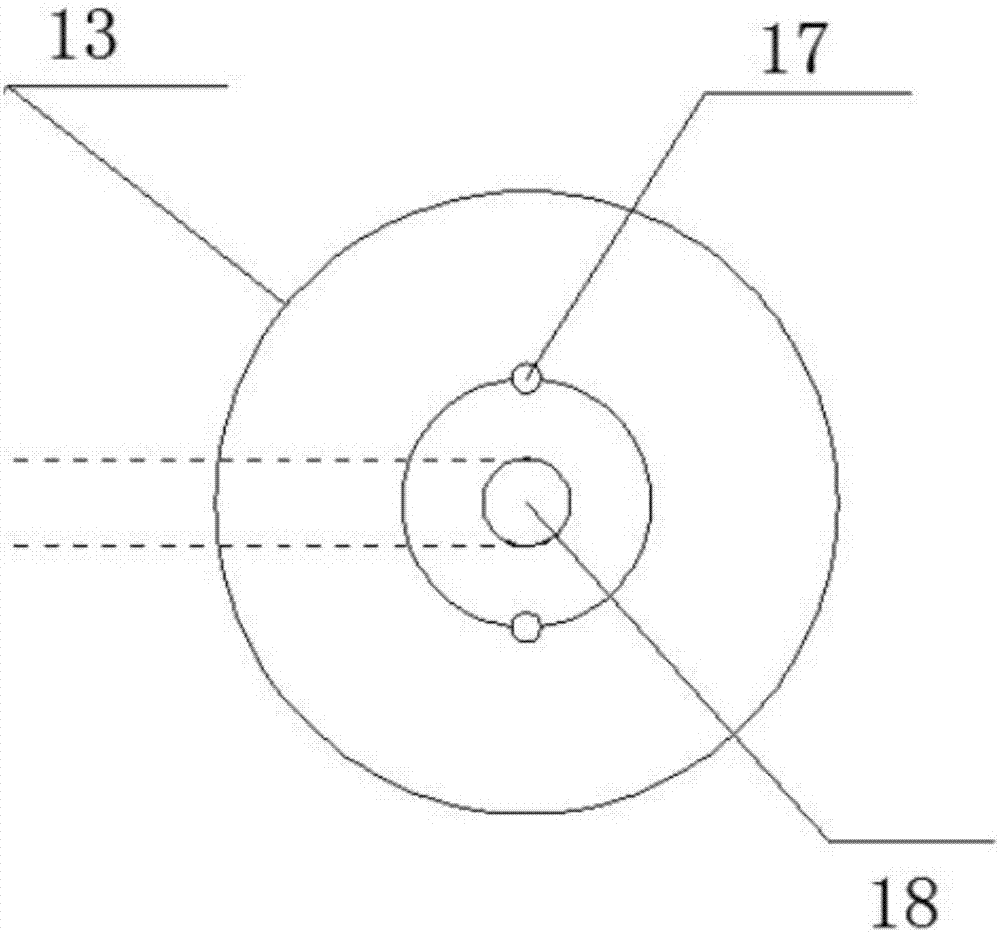

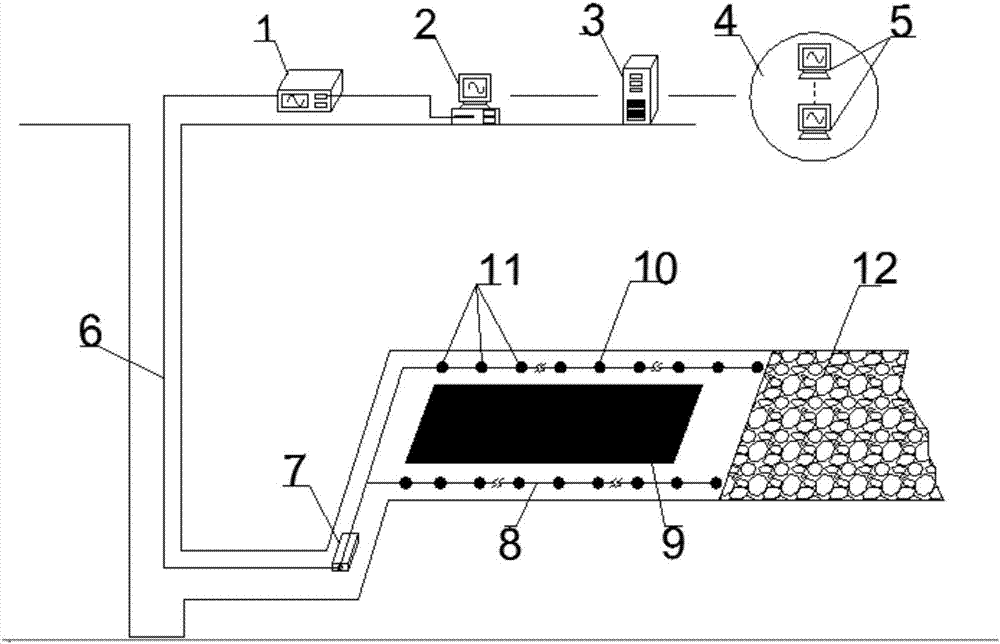

[0040] Embodiment 1: A coal mine roadway roof stress online monitoring device based on a fiber grating sensor, the number of monitoring stations is reasonably arranged in the section roadway, and the monitoring stations 11 are arranged at intervals of 3 roadway roof stress online monitoring devices 10, and the distance between them is 50 meters, connect the optical fiber pigtail at the leading end of the fiber grating sensor 10 with the communication optical fiber 8, connect the communication optical fiber with the mine transmission optical cable 6 through the optical fiber terminal box 7, and connect the mine transmission optical cable 6 with the fiber grating static demodulator 1 The input end is connected, the output end of the fiber grating static demodulator 1 is connected with the monitoring computer 2, and the monitoring computer 2 performs data sharing with the client 5 through the network server 3 and the coal mine local area network 4, forming an online network of full...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com