Impact test bed

A technology of impact test and workbench, which is applied in the direction of impact test, machine/structural component test, measuring device, etc. It can solve the problems of time-consuming and labor-intensive testing of test equipment, high cost of use and maintenance, and difficulty in test adjustment. The effect of small area, convenient operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

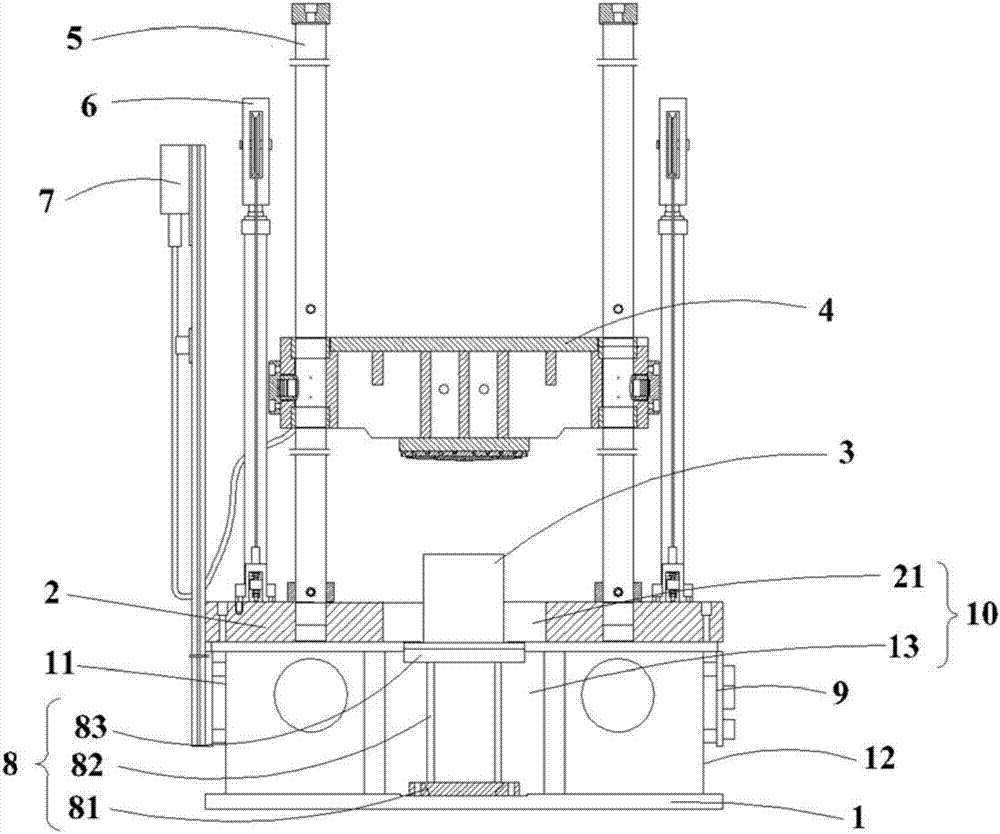

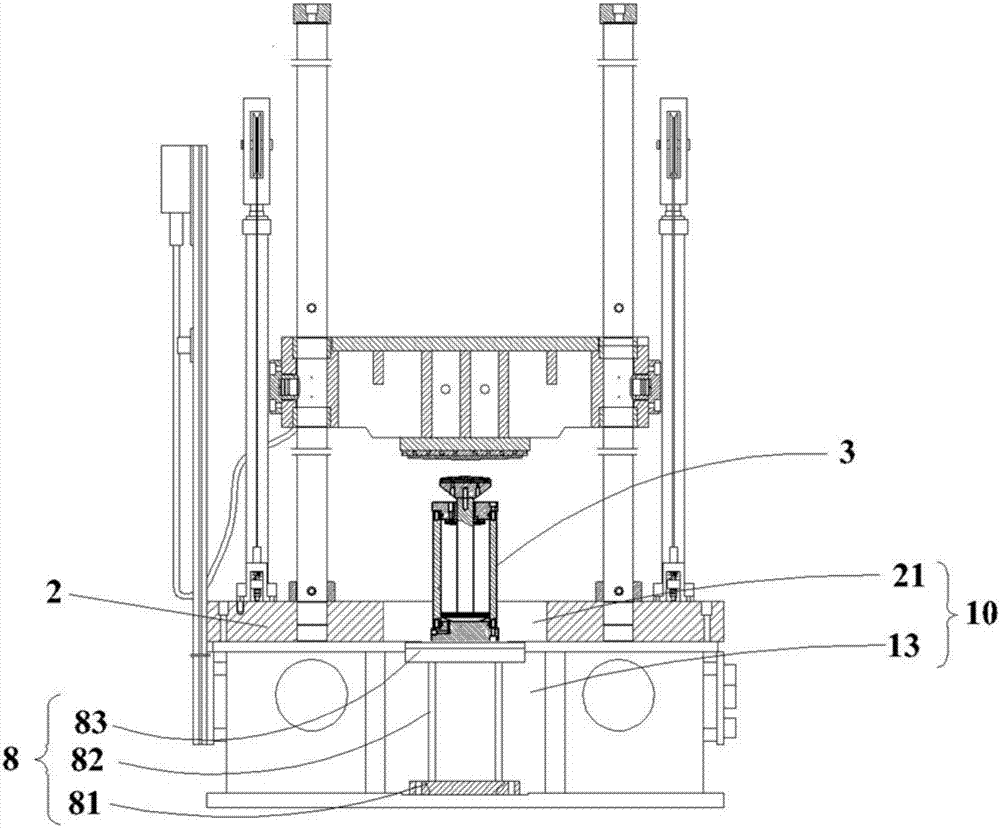

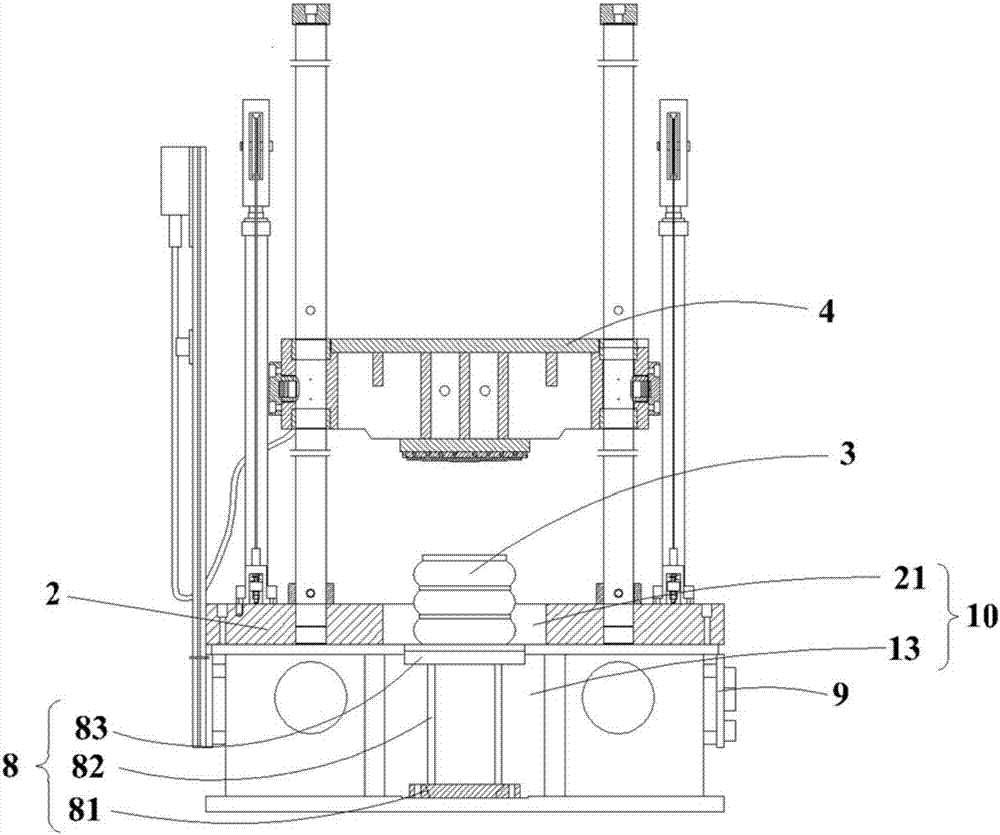

[0024] See figure 1 , The shock test bench of the present invention includes a base 1 , a shock mount 2 , a waveform generator 3 , a workbench 4 , a slide bar 5 , a driving device 6 and a power supply device 7 . The base 1 has opposite left sides 11 and right sides 12, a first cavity 13 is provided in the base 1, the impact fixing seat 2 is arranged on the base 1, and a second cavity is provided in the impact fixing seat 2 21 , the first cavity 13 communicates with the second cavity 21 to form a mounting groove 10 , and the waveform generator 3 is partially or completely disposed in the mounting groove 10 . In this embodiment, the installation groove 10 is a square struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com