A thermal shock assessment test platform for lateral rotation of specimens

A technology of test testing and thermal shock, applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of long test preparation time, unstable test bench structure, inconvenient temperature measurement, etc., and achieve work efficiency High, saving test costs, shortening the effect of test preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

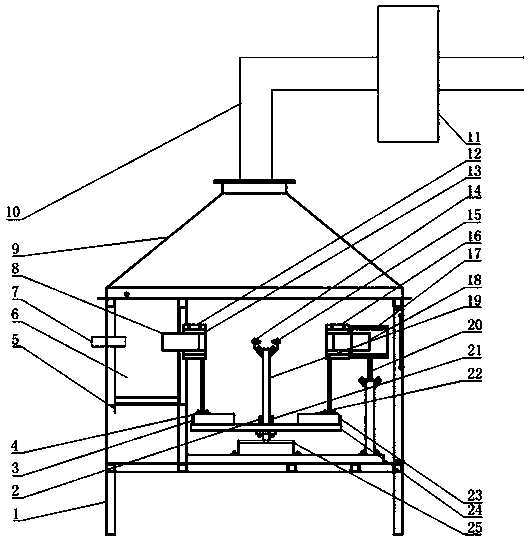

Embodiment 1

[0024] Embodiment 1: as figure 1 As shown in the figure, a thermal shock assessment test platform for the lateral rotation of the test piece includes a test bench support 1, a position sensor II2, a position sensor I3, a linear cylinder I4, a heat preservation chamber 6, a fixture I12, an infrared thermometer I14, an infrared measuring instrument Thermometer II15, fixture II16, cooler 17, straight rod I19, straight rod II20, position sensor III21, linear cylinder II22, position sensor IV23, guide rail 24, swing cylinder 25; the test bench support 1 is equipped with a heat preservation chamber 6 , the fixture I12 and the fixture II16 clamp the test piece I8 and the test piece II18 respectively, the fixture I12 and the fixture II16 are connected to the linear cylinder I4 and the linear cylinder II22 through the connecting rod, the straight rod I19 is installed on the guide rail 24, and the top of the straight rod I19 The infrared thermometer I14 and the infrared thermometer II15...

Embodiment 2

[0025] Embodiment 2: as figure 1As shown, a thermal shock assessment test platform for test piece laterally rotating, this embodiment is the same as Example 1, wherein a smoke hood 9 is installed on the upper part of the assessment test platform, and the smoke hood 9 is connected to the smoke exhaust pipe 10, and the smoke exhaust pipe 10 is connected A high-temperature duct exhaust fan 11 is installed on the smoke pipe 10 . The hot air inside the test bench can be extracted to ensure that the position sensor II2, position sensor I3, infrared thermometer I14, infrared thermometer II15, position sensor III21, linear cylinder II22, position sensor IV23, guide rail 24, and swing cylinder 25 are normal. working environment temperature.

Embodiment 3

[0026] Embodiment 3: as figure 1 As shown, a test platform for a thermal shock assessment test in which the specimen rotates laterally, this embodiment is the same as the embodiment 1, wherein the fixture I12 and the fixture II16 are inlaid with a heat insulating layer 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com