Automobile body cementing structure health monitoring system

An automobile body and bonding technology, applied in the direction of material resistance, can solve the problems of difficult joint quality inspection, large environmental impact, low bonding peel strength, etc., to avoid sudden breakage, save materials, and promote intelligent development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

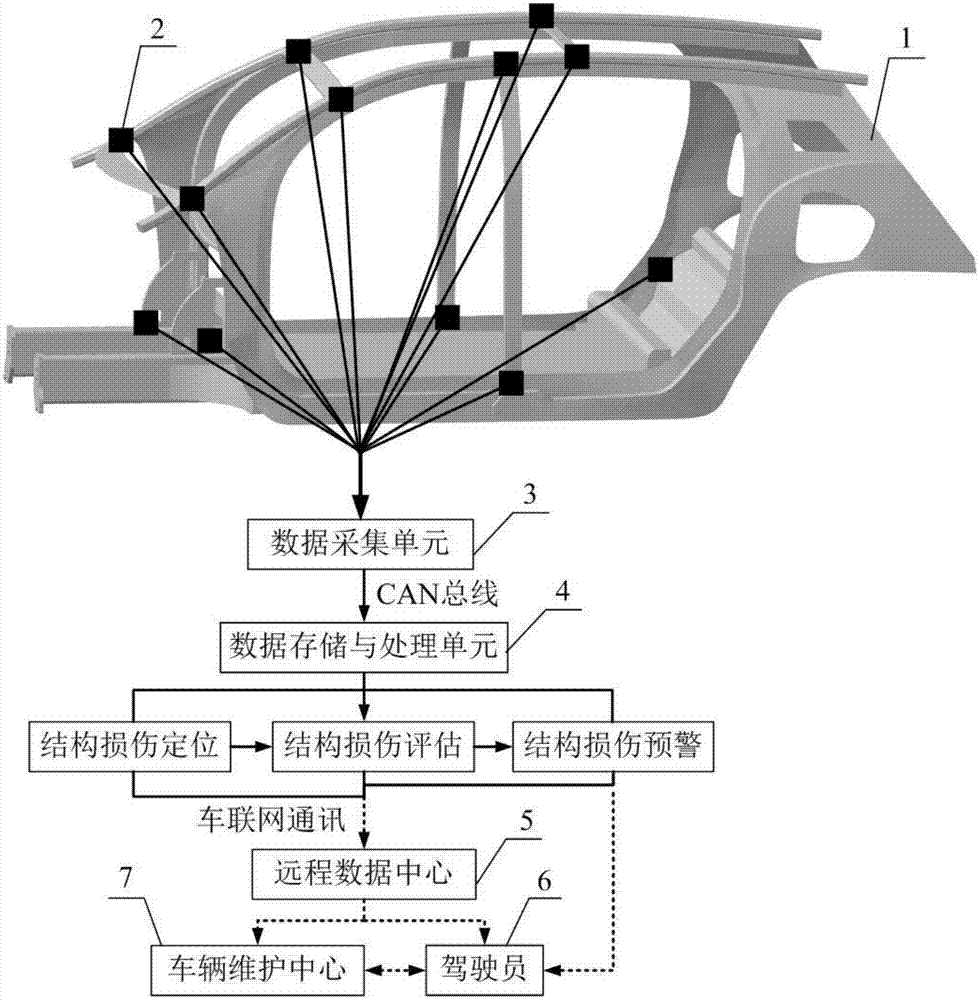

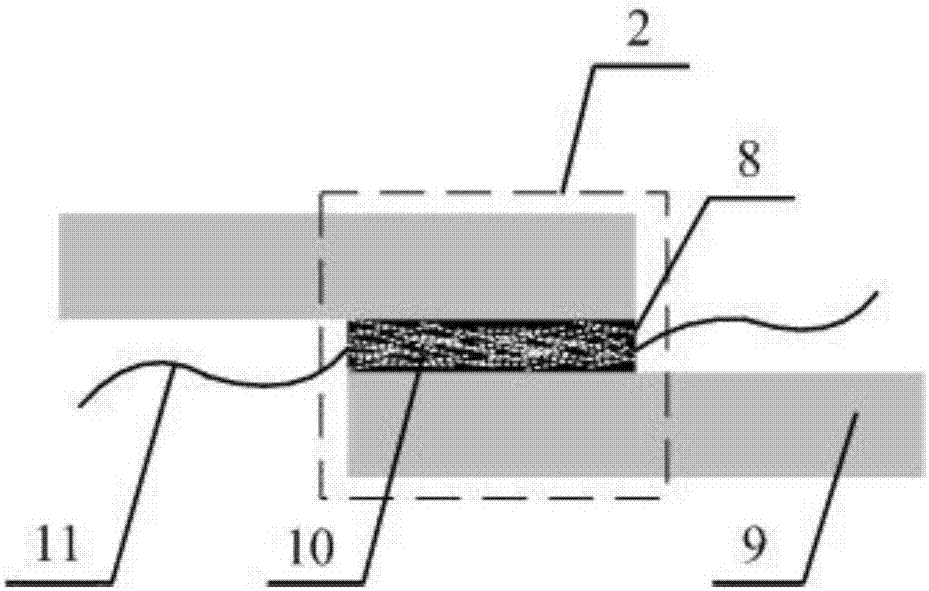

[0025] As shown in the accompanying drawings, a health monitoring system for an automobile body glued structure of the present invention includes the following components: a body 1, a glued structure 2, a data acquisition unit 3, a data storage and processing unit 4, a remote data center 5, a driver 6. Vehicle maintenance center 7 , adhesive layer 8 , connected material 9 , conductive filler 10 , wire 11 .

[0026] The relationship between them is: the glued structure 2 is located at the connection of the beams, plates and other components in the body 1; in the glued structure 2, the material to be connected 9 is glued together by the glue layer 8; the conductive filler 10 Evenly dispersed in the adhesive layer; the data acquisition unit 3 is connected with each adhesive structure 2 in the body 1 through the wire 11; the data storage and processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com