Tuning peg trimmer and tuning peg fine tuning tool set

A technology of trimmers and pegs, applied to stringed instruments, instruments, musical instruments, etc., can solve the problems of time-consuming and labor-intensive tuning of pegs, and achieve the effects of convenient tuning, noise avoidance, and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

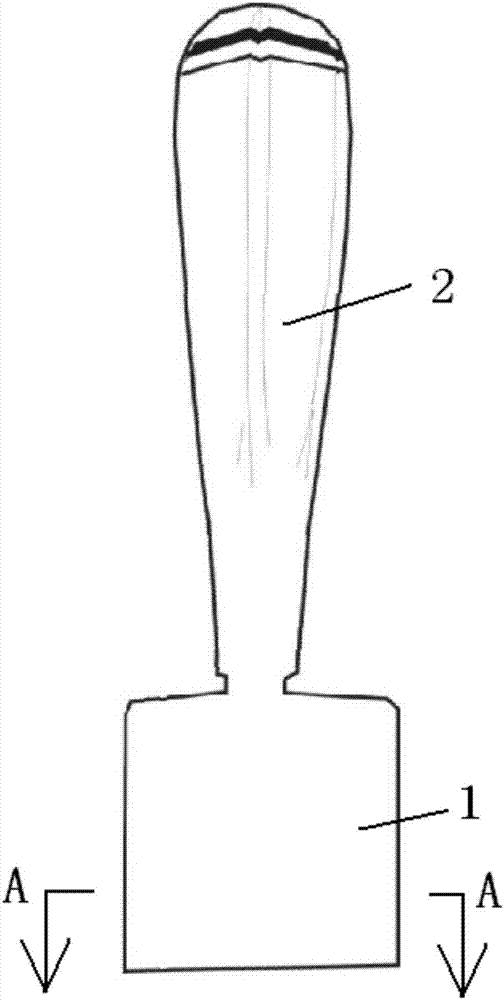

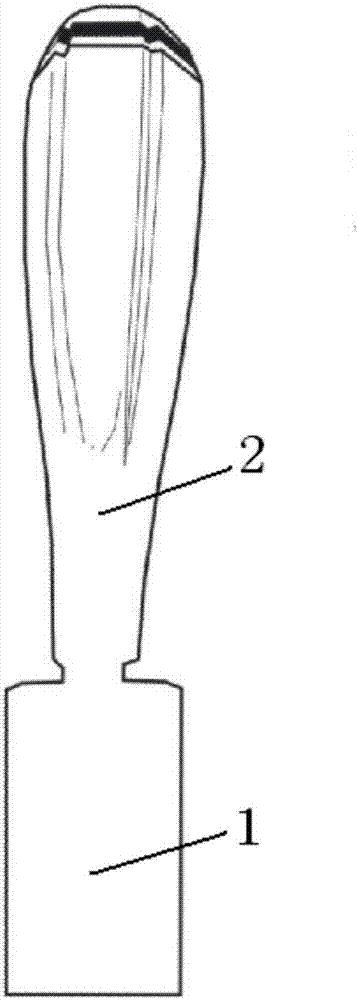

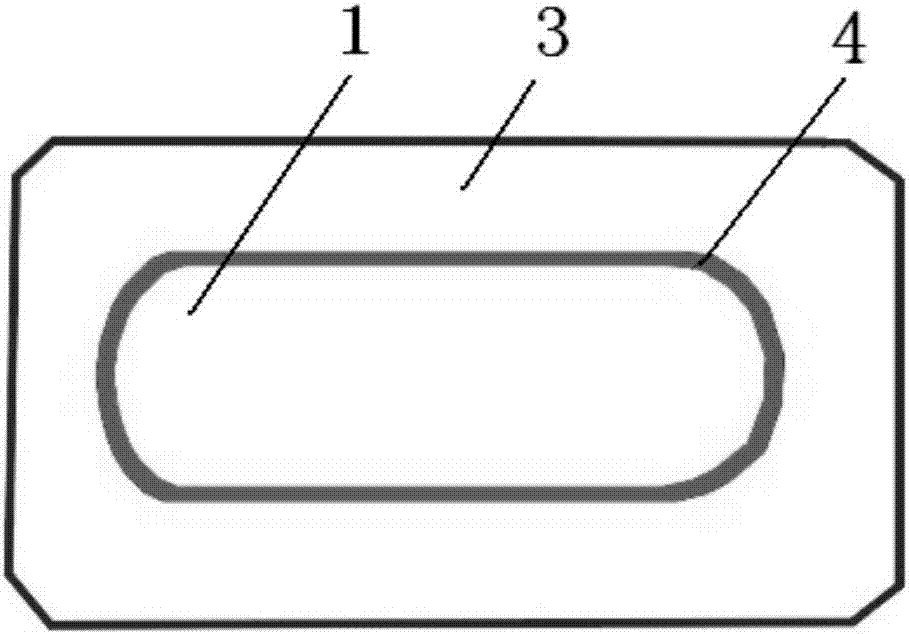

[0052] As the first implementation mode in this embodiment, such as Figure 1 to Figure 3 As shown, the lower end of the twisting head 2 is connected and fixed to the sleeve end 1, and the twisting head 2 and the sleeve end 1 are of an integral structure. The sleeve end 1 is roughly in the shape of a flat block, the twist head 2 is roughly in the shape of a drop-shaped column, the insertion area 3 is a flat hole, the center line of the insertion area 3 coincides with the center line of the twist head 2, and the sleeve End 1 has a uniform wall thickness.

[0053] The meaning of the flat block structure is that the sleeve end 1 is in image 3 The size of the left and right direction is more than 1.5 times the size of the up and down direction, and the meaning of the flat hole is that the insertion area 3 is in the image 3 The dimension in the left-right direction is 1.5 times or more the dimension in the up-down direction. The twist head 2 is roughly drop-shaped and has a co...

Embodiment 2

[0063] As the first embodiment in this embodiment, the twist head 2 includes a connecting rod 10 and a turntable 11, one end of the connecting rod 10 is connected and fixed to the sleeve end 1, and the other end of the connecting rod 10 is connected and fixed to the turntable 11, and the sleeve end 1 is connected and fixed. The center line, the center line of the plug-in area 3, the center line of the connecting rod 10 and the center line of the turntable 11 coincide, and the edge of the turntable 11 is provided with an additional handle 6, which is rod-shaped, and one end of the additional handle 6 is connected to the turntable 11. The edge of is detachably connected, and the center line of the additional handle 6 intersects and is perpendicular to the center line of the turntable 11, such as Figure 10 shown. The additional handle 6 can be a telescopic rod.

[0064] One end of the additional handle 6 can be provided with a convex head 8, and the edge of the rotating disk 11...

Embodiment 3

[0070] This embodiment is an improvement made on the basis of Embodiment 2. The twisting head 2 is provided with an electronic tuner, and the surface of the twisting head 2 is provided with each string display lamp 13, audio display lamp 12 and audio frequency contrast dial 14 of the electronic tuner, such as Figure 15 with Figure 16 shown.

[0071]Specifically, the twisting head 2 contains a connecting rod 10 and a turntable 11, and the electronic tuner is arranged in the connecting rod 10, that is, the connecting rod 10 is made into a connecting rod with an electronic tuner, each string display lamp 13 and an audio display Lamp 12 can protrude from the surface of the connecting rod to facilitate observation. Two groups of lamps or connecting rods are made of transparent materials, which can avoid the problem of observing dead angles. The audio level contrast dial 14 is the corresponding audio level contrast of the display lamp. The usage method of example 2 can observe t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com