Outdoor dry-type transformer

A dry-type transformer, outdoor technology, applied in the field of transformers, can solve the problems of large thickness of cast connection body, difficult to resist harsh environment, easy aging, deformation and cracking, etc., achieve the effect of small deformation, resistance to harsh environment, and increase short-circuit resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

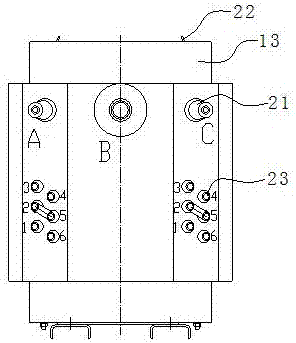

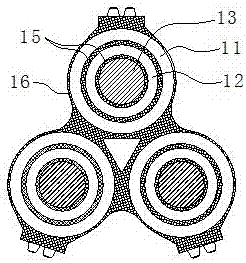

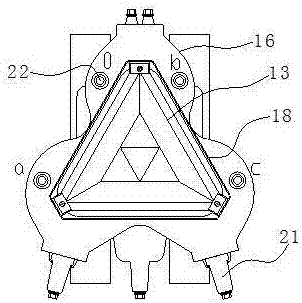

[0015] Such as Figure 1~Figure 3 As shown, an outdoor dry-type transformer of the present invention includes a high-voltage coil 11, a low-voltage coil 12, an iron core 13, and a partition wall 15 that is filled with a space between the high and low-voltage coils and between the coil and the iron core 13 by resin casting, The outer wall 16 of the high and low voltage coils and the iron core is formed and covered by resin casting, the outer wall 16 connects the three groups of coils as a whole, and the iron core 13 is a closed three-dimensional wound iron core. Since there is no seam in the closed three-dimensional wound core 13, and the three-phase magnetic circuit is completely symmetrical, the no-load current, no-load loss and noise are greatly reduced. Between the high and low voltage coils, the insulation between the low volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com