Permanent magnet compound direct drive motor

A direct drive motor, permanent magnet technology, applied in synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of high cost, difficult industrialization, difficult design, manufacture, and assembly of magnetic control rings, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

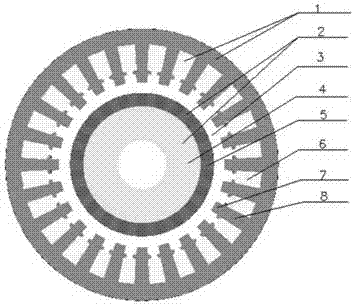

[0021] A permanent magnet composite direct drive inner rotor motor provided in this embodiment is more specifically a permanent magnet composite direct drive inner rotor motor, which is characterized in that it includes an iron core stator 1 and a permanent magnet rotor 2, and the iron core stator There is an air gap 3 between 1 and the permanent magnet rotor 2; the iron core stator 1 is composed of a winding 6 and a magnetically permeable material sheet 8 with slots; the teeth of the magnetically permeable material 8 protrude radially outward in a block shape or The shape forms a magnetic modulation block 7, and a plurality of magnetic modulation blocks 7 along the circumferential direction form a magnetic modulation ring; the permanent magnet rotor 2 is composed of several permanent magnets 5 and a yoke 4.

[0022] When the stator coil of the motor is energized, the coil induced magnetic field is modulated by the special modulation ring, and the modulated magnetic field is th...

Embodiment 2

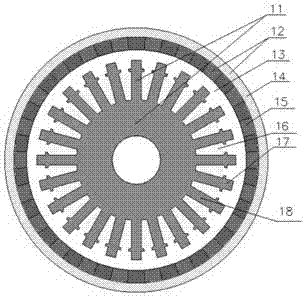

[0026] This embodiment provides a permanent magnet composite direct drive external rotor motor, more specifically a permanent magnet composite direct drive external rotor motor, which is characterized in that it includes an iron core stator 11 and a permanent magnet rotor 12, and the iron core stator 11 Inside the permanent magnet rotor 12, there is an air gap 13 between the iron core stator 11 and the permanent magnet rotor 12; the iron core stator 11 is composed of a winding 16 and a magnetic material sheet 18 with tooth slots; the tooth edges of the magnetic material 18 A magnetic modulation block 17 protrudes radially outward in the shape of a block or other shapes, and a plurality of magnetic modulation blocks 17 along the circumferential direction form a magnetic modulation ring; the permanent magnet rotor 12 is composed of several permanent magnets 15 and a yoke 14 .

[0027] When the iron core stator coil is energized, the inductive magnetic field is adjusted through th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap