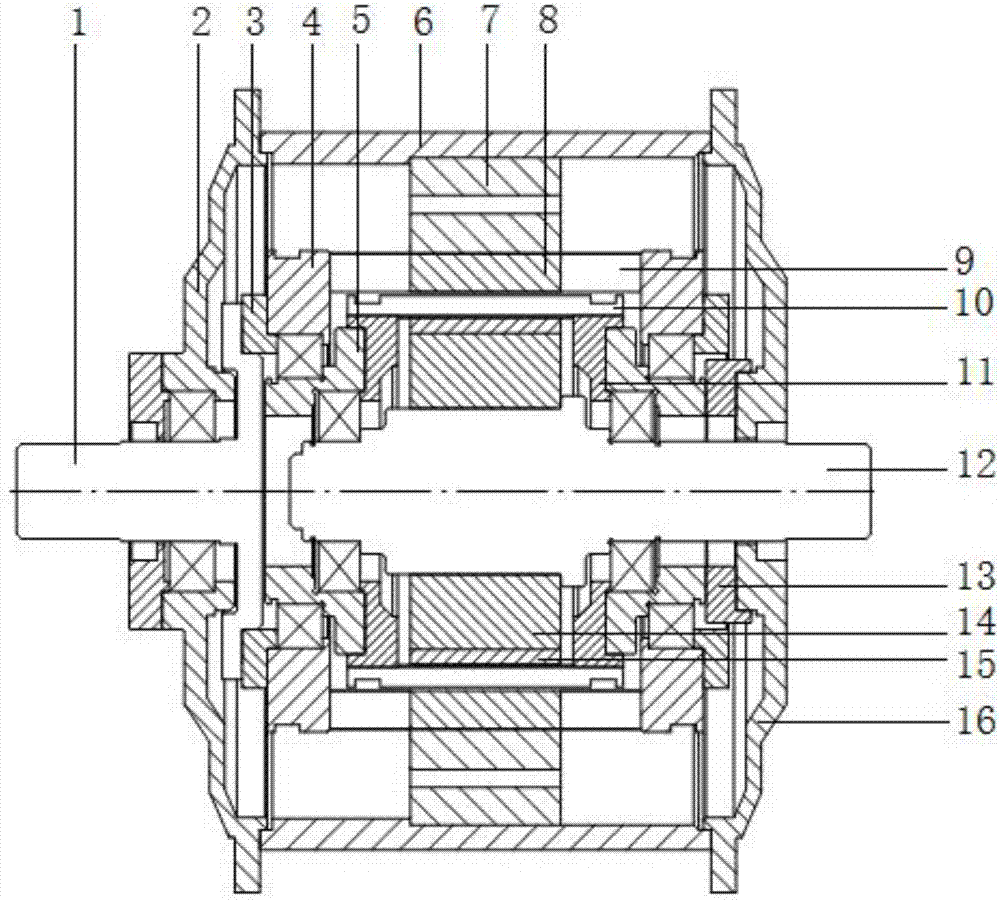

Magnetic coupling transmission device

A transmission device, magnetic coupling technology, applied in the direction of permanent magnet clutch/brake, electromechanical device, electric vehicle, etc., can solve the problems of complex structure and difficult assembly process, achieve small size, low assembly process difficulty, reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

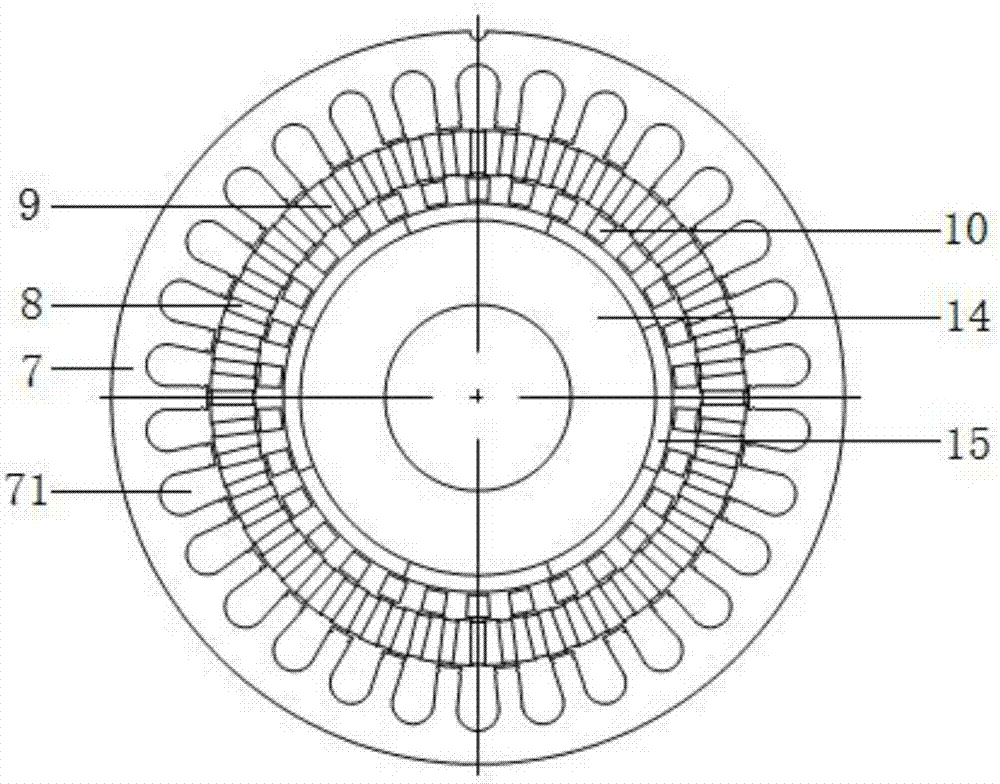

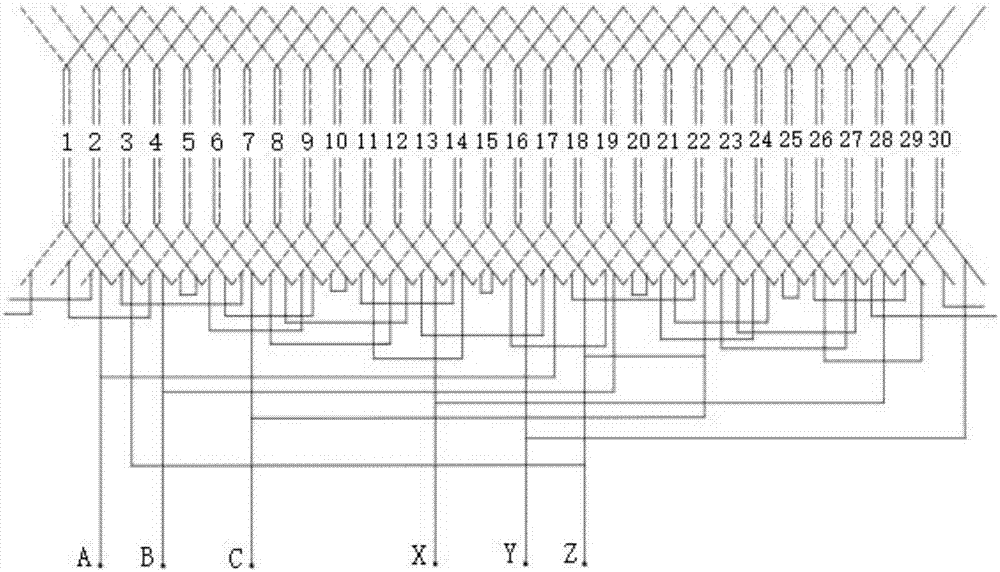

Embodiment 1

[0041] Embodiment 1 of the present invention: when three-phase alternating current is passed into the armature winding, the outer rotor shaft and the inner rotor shaft can be simultaneously driven to rotate through magnetic coupling, and the outer rotor shaft and / or the inner rotor shaft are used as output terminals to connect to an external load. Now the present invention is used as a permanent magnet motor; wherein the outer rotor shaft rotational speed is lower, while the inner rotor shaft rotational speed is higher, and the rotational direction of the outer rotor shaft and the inner rotor shaft is opposite; the calculation formula of both rotating speeds is as follows: Let f is the current frequency, P in is the number of pole pairs of the inner rotor permanent magnet, P out is the number of pole pairs of the permanent magnet of the outer rotor, then the shaft speed of the inner rotor n in =60f / P in , the rotational speed of the outer rotor shaft n out =P in ×n in / P ...

Embodiment 2

[0042] Embodiment 2 of the present invention: When the armature winding is not energized or the armature winding is not installed, the outer rotor shaft or the inner rotor shaft is connected to the external power as the input end, and the corresponding other end is connected to the external load as the output end. At this time, the magnetic coupling transmission device can be used as a speed changer; if the outer rotor shaft is used as the input end to connect with the external power, and the inner rotor shaft is used as the output end to connect with the external load, then the present invention can be used as a speed increaser; if the inner rotor shaft The shaft is connected with external power as an input end, and the outer rotor shaft is connected with an external load as an output end. At this time, the present invention is used as a reducer to increase output torque.

Embodiment 3

[0043] Embodiment 3 of the present invention: when the outer rotor shaft or inner rotor shaft is used as the input end to connect with external power and drive to rotate, a three-phase alternating current can be generated in the armature winding of the outer stator, and at the same time, the armature winding is used as the output end to connect to the external When the load is on, the present invention can be used as a generator at this time, and is especially suitable for low-speed, high-torque applications such as wind power generation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com