Making method of black tea having fragrance of flowers

A production method and technology of black tea, applied in tea processing before extraction, etc., can solve problems such as monotonous taste of black tea, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

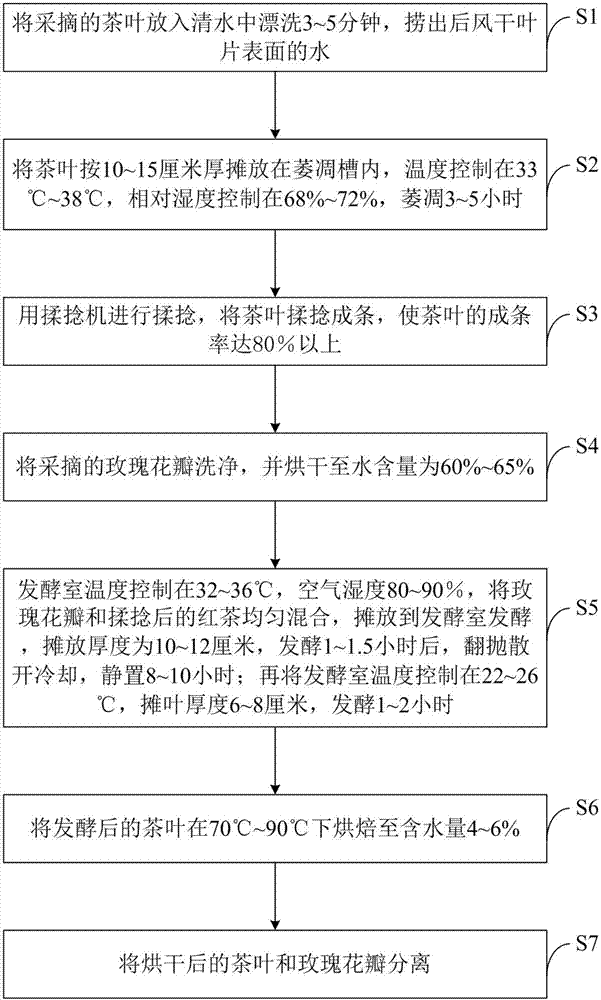

[0034] The preparation method of the floral-scented black tea of the present embodiment comprises:

[0035] Step S1, rinsing the picked tea leaves in clean water for 4 minutes, removing and air-drying the water on the surface of the leaves.

[0036] Step S2, spreading the tea leaves in a withering tank with a thickness of 12 cm, controlling the temperature at 36° C. and controlling the relative humidity at 70%, and withering for 4 hours.

[0037] Step S3, kneading with a kneading machine, kneading the tea leaves into slivers, so that the sliver rate of the tea leaves can reach more than 80%.

[0038] In step S4, the picked rose petals are washed and dried until the water content is 62%.

[0039] In step S5, the temperature of the fermentation room is controlled at 34°C and the air humidity is 85%. Mix the rose petals and the rolled black tea evenly, and spread them in the fermentation room to ferment. The thickness of the spread is 11 cm. After 1.2 hours of fermentation, tu...

Embodiment 2

[0047] The preparation method of the floral-scented black tea of the present embodiment comprises:

[0048] Step S1, rinsing the picked tea leaves in clean water for 5 minutes, removing and air-drying the water on the surface of the leaves.

[0049] Step S2, spreading the tea leaves in a withering tank with a thickness of 10 cm, controlling the temperature at 33° C. and controlling the relative humidity at 68%, and withering for 3 hours.

[0050] Step S3, kneading with a kneading machine, kneading the tea leaves into slivers, so that the sliver rate of the tea leaves can reach more than 80%.

[0051] In step S4, the picked rose petals are washed and dried until the water content is 60%.

[0052] Step S5, the temperature of the fermentation room is controlled at 36°C, and the air humidity is 80%. Mix the rose petals and the rolled black tea evenly, and spread them in the fermentation room to ferment. The thickness of the spread is 12 cm. After 1.5 hours of fermentation, turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com