High-tension heavy anchoring and mooring machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, specific modes for implementing the present invention will be described with reference to the accompanying drawings.

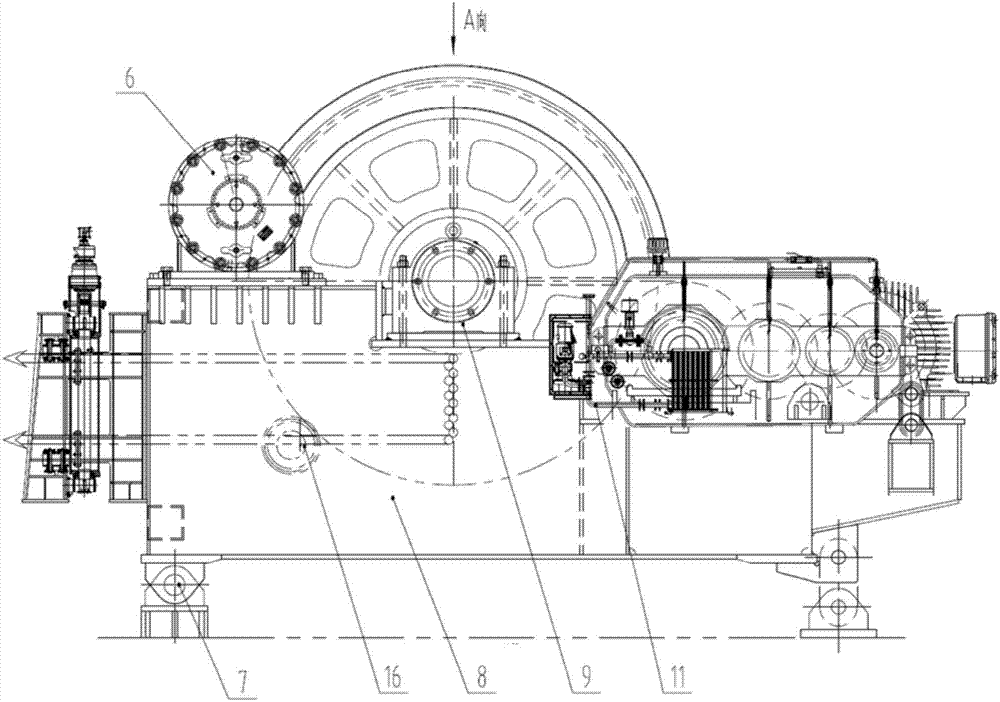

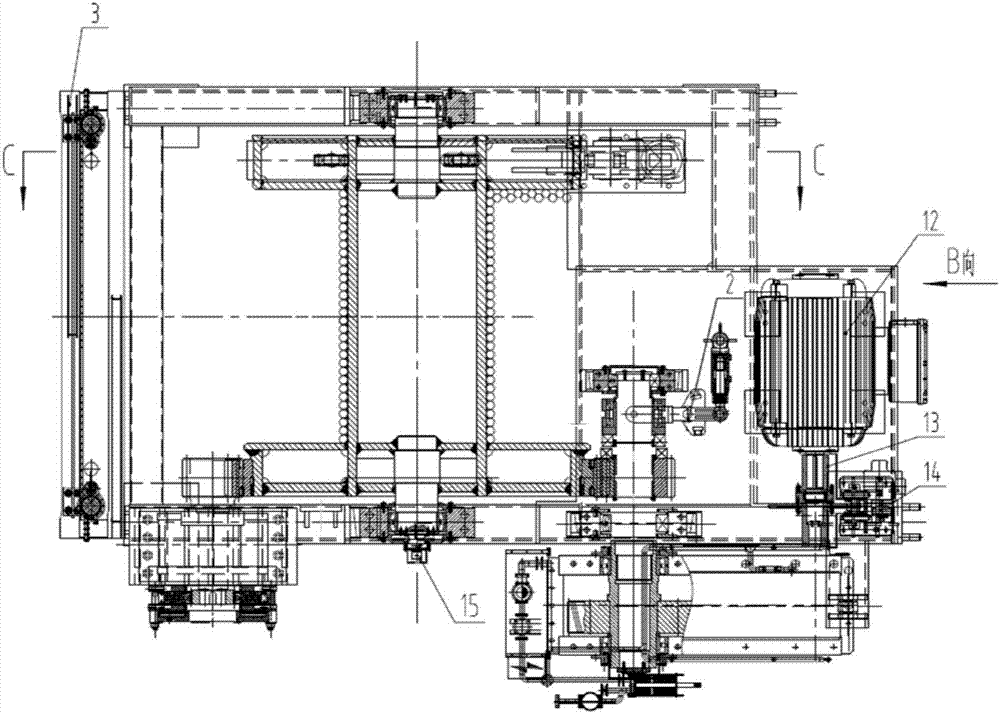

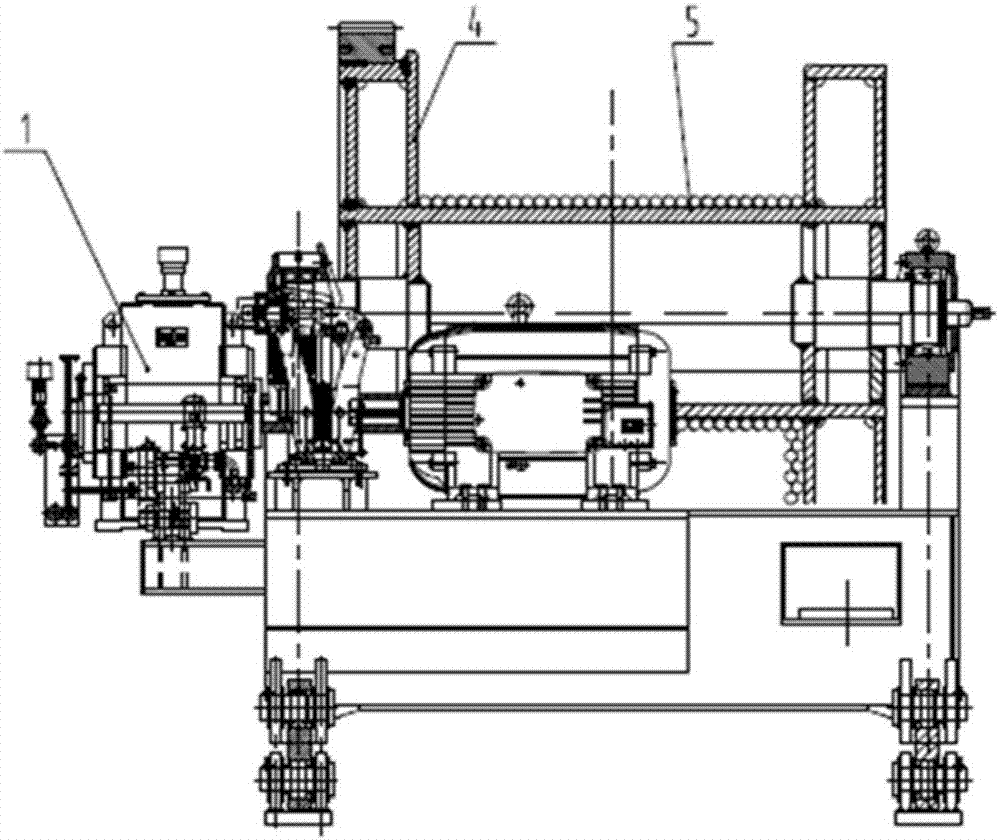

[0020] figure 1 It is the front view of the large tension heavy-duty anchor winch of the present invention, figure 2 for from figure 1 The A direction observes the figure of the large tension heavy-duty anchor winch of the present invention, image 3 for from figure 2 The B direction of B direction observes the figure of the heavy-duty anchor winch of the present invention, Figure 4 for from figure 2 A cross-sectional view along line C-C.

[0021] Such as Figure 1 ~ Figure 4 As shown, the large-tension heavy-duty anchor winch of the present invention includes a reduction box 1, a clutch 2, a rope puller 3, a reel 4, a round steel type broken line rope groove 5, a water-cooled brake 6, a force measuring device 7, a frame 8, Bearing block 9, rope pressing device 10, gear box lubricating device 11, motor 12, shaft coupling 13, high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com