Device and method for conveying pipe column to center of wellhead in horizontal state

A horizontal state, center line position technology, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems that affect the efficiency of drilling operations, and achieve the effects of improving drilling efficiency, reducing drilling costs, and reducing transportation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

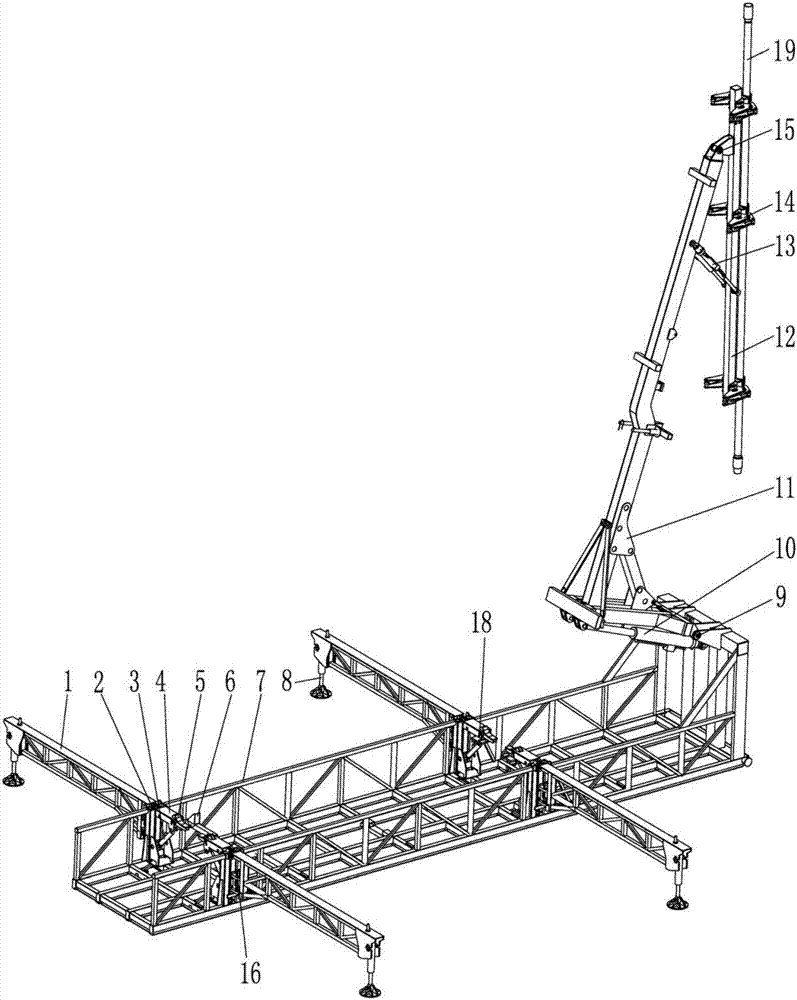

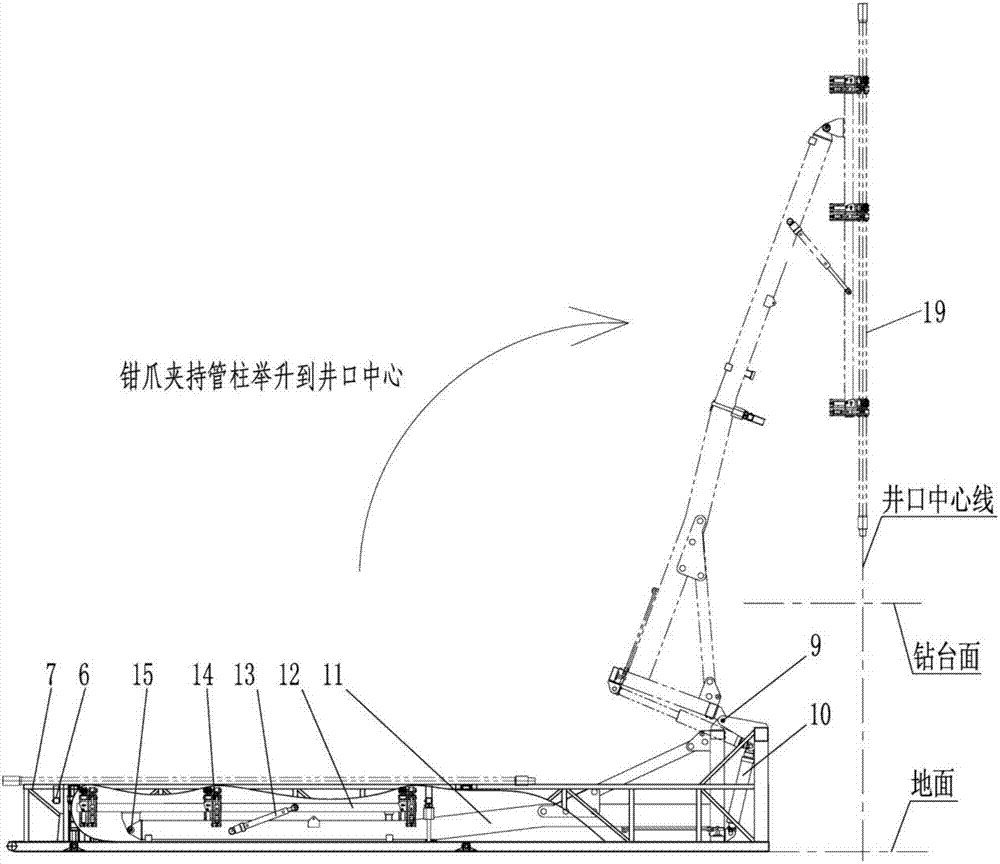

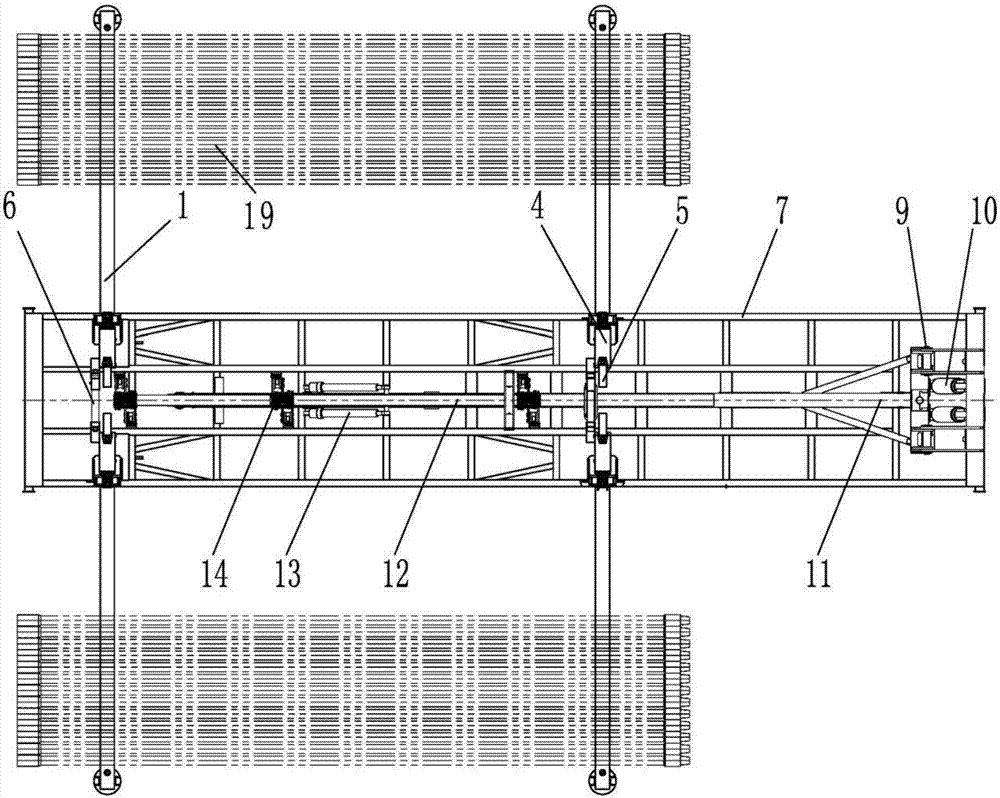

[0021] refer to figure 1 , figure 2 , Figure 4 , Figure 5 , the structure of the device of the present invention is that the catwalk frame body 7 is fixedly installed on the front side of the drilling rig drill floor and the wellhead centerline position, and is outside the catwalk frame body 7 (away from the wellhead end, i.e. figure 2 The left side of the front, rear, left and right are respectively hinged with a set of pipe racks 1 through a pin shaft Ⅳ16, and there are four sets of pipe racks 1 in total. The outer end of each pipe rack 1 is hinged downward with a row The pipe rack liquid cylinder 8, the support seat of each pipe rack liquid cylinder 8 is placed on the ground; an inclined beam 4 is hinged on the inner side of the catwalk frame body 7 corresponding to each pipe rack 1 through a pin shaft I2, and each The inner end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com