Small-inertia finite angle sensor

A technology with limited angles and sensors, applied in the field of sensors, can solve problems such as inflexible response and poor measurement accuracy, and achieve the effects of avoiding mutual interference, facilitating operation, and reducing moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

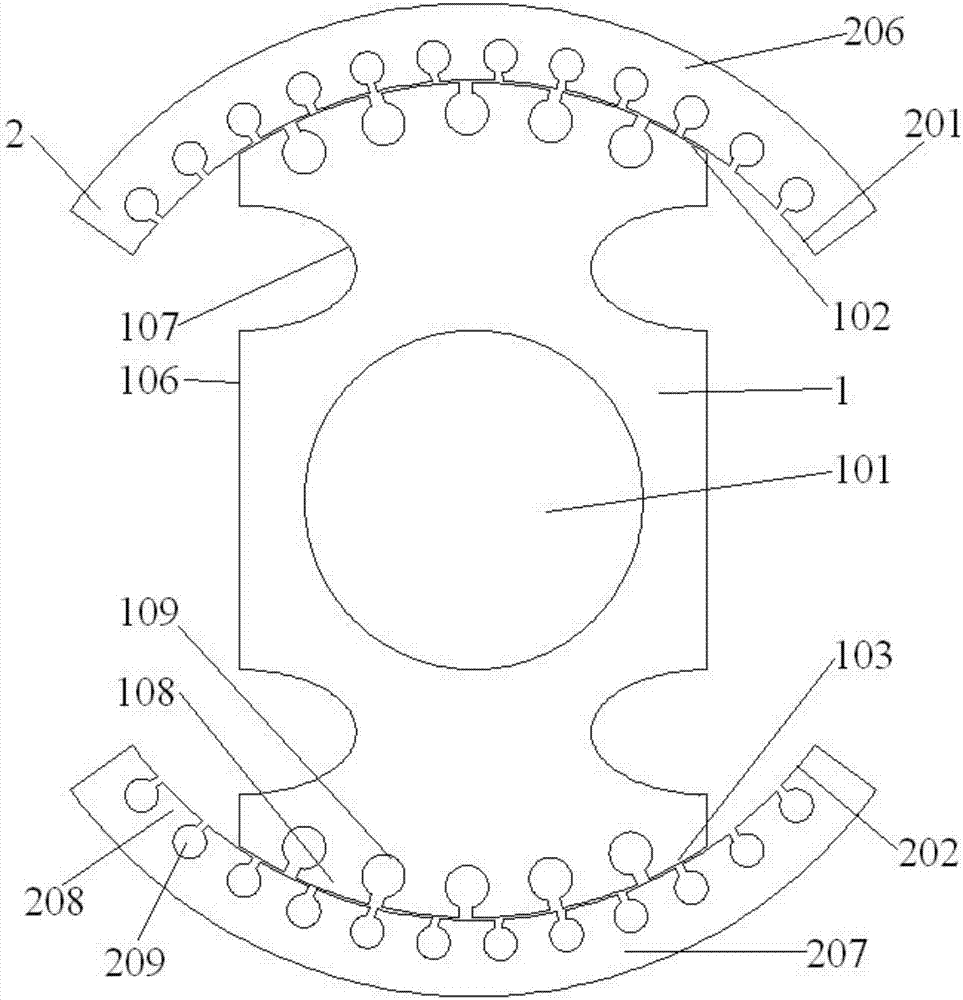

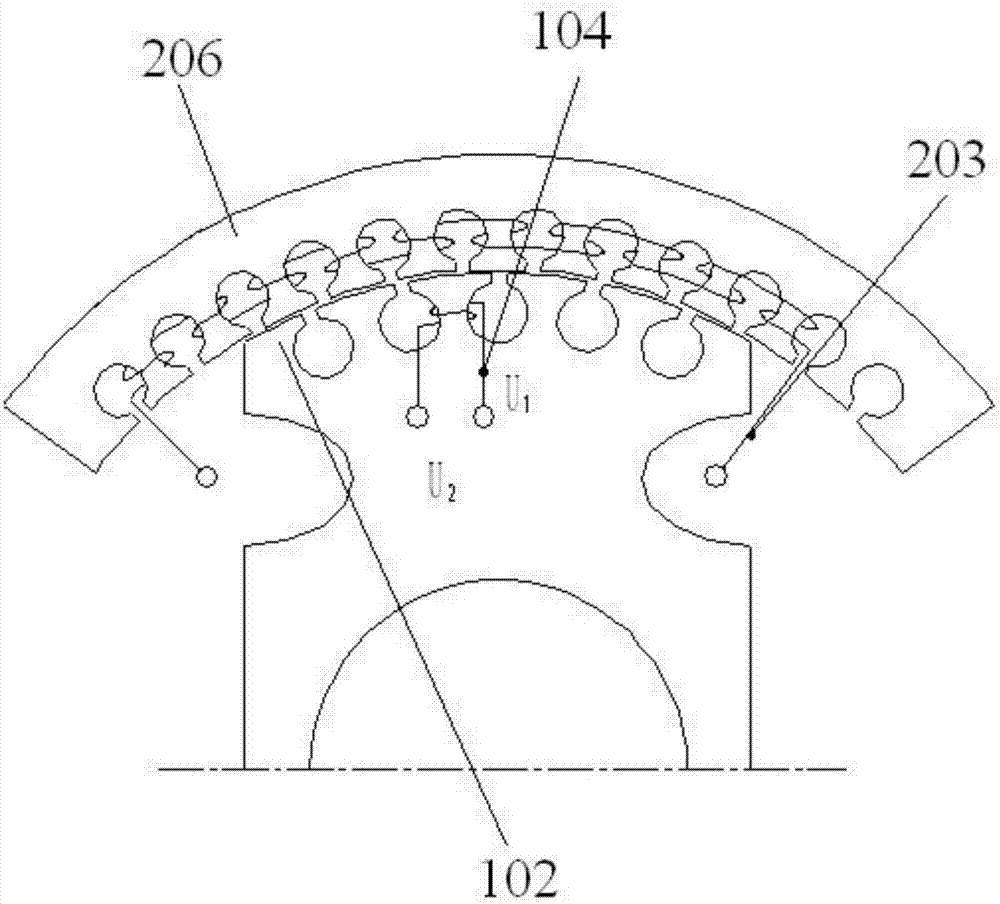

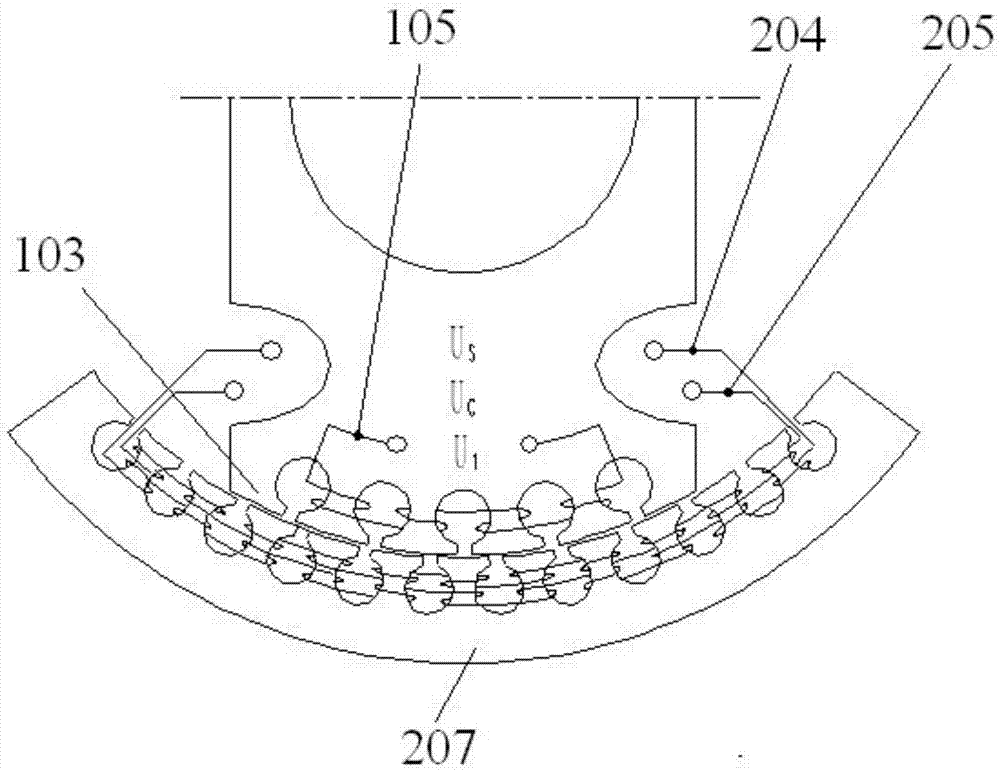

[0021] refer to Figure 1 to Figure 3 , the embodiment of the present invention proposes a small inertia limited angle sensor, comprising: a rotor 1 and a stator 2; a shaft hole 101 is arranged in the middle of the rotor 1, and a first outer arc segment 102 and a second arc segment are symmetrically arranged on the side wall of the rotor 1 Two outer circular arc sections 103, the first outer circular arc section 102 is provided with a rough machine excitation winding 104, the second outer circular arc section 103 is provided with a fine machine excitation winding 105; the stator 2 is symmetrically provided with a first inner circular arc segment 201 and the second inner arc segment 202, the first inner arc segment 201 is located at the periphery of the first outer arc segment 102, the second inner arc segment 202 is located at the periphery of the second outer arc segment 103, the first inner arc segment The circular arc section 201 is provided with a rough machine linear outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com