Desulfurization agent as well as preparation method and application thereof

A desulfurizer, potassium permanganate technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of inability to remove sulfur dioxide, complex preparation process, general desulfurization effect, etc., to achieve good market value, guarantee Removal efficiency, rapid response and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

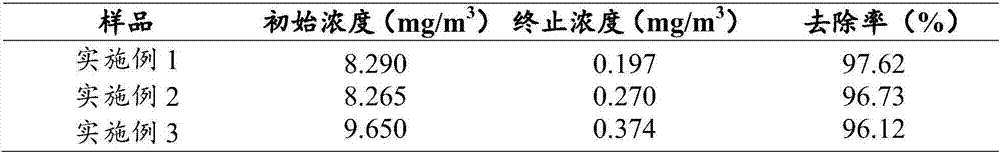

Embodiment 1

[0033] An embodiment of the desulfurizing agent of the present invention, the desulfurizing agent described in this embodiment comprises potassium permanganate and attapulgite, and the weight ratio of the potassium permanganate to the attapulgite is: potassium permanganate : Attapulgite = 1: 50.

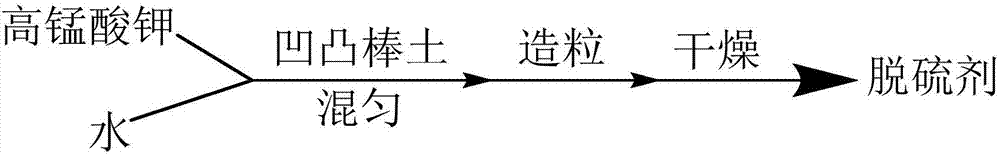

[0034] A kind of preparation method of desulfurizer described in the present invention, comprises the steps:

[0035] ①Dissolve 10g of potassium permanganate in 500g of water to obtain potassium permanganate solution;

[0036] ② Slowly add potassium permanganate solution into 500g attapulgite and mix well;

[0037] ③Granulation by granulator;

[0038] ④ Dry at 100°C for 6 hours to obtain a desulfurizing agent.

Embodiment 2

[0040] An embodiment of the desulfurizing agent of the present invention, the desulfurizing agent described in this embodiment comprises potassium permanganate and attapulgite, and the weight ratio of the potassium permanganate to the attapulgite is: potassium permanganate : Attapulgite = 0.5: 40.

[0041] A kind of preparation method of desulfurizer described in the present invention, comprises the steps:

[0042] ①Dissolve 5g of potassium permanganate in 500g of water to obtain potassium permanganate solution;

[0043] ② Slowly add potassium permanganate solution to 400g attapulgite and mix well;

[0044] ③Granulation by granulator;

[0045] ④ Dry at 110°C for 5 hours to obtain a desulfurizing agent.

Embodiment 3

[0047] An embodiment of the desulfurizing agent of the present invention, the desulfurizing agent described in this embodiment comprises potassium permanganate and attapulgite, and the weight ratio of the potassium permanganate to the attapulgite is: potassium permanganate : Attapulgite = 1.5: 60.

[0048] A kind of preparation method of desulfurizer described in the present invention, comprises the steps:

[0049]①Dissolve 15g of potassium permanganate in 500g of water to obtain potassium permanganate solution;

[0050] ② Slowly add potassium permanganate solution to 600g attapulgite and mix well;

[0051] ③Granulation by granulator;

[0052] ④ Dry at 90°C for 7 hours to obtain a desulfurizing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com