Hydrocracking catalyst and preparation method thereof

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of different properties, catalyst performance differences, low catalytic activity, etc., to increase active centers and control cracking. degree, the effect of reducing coke yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

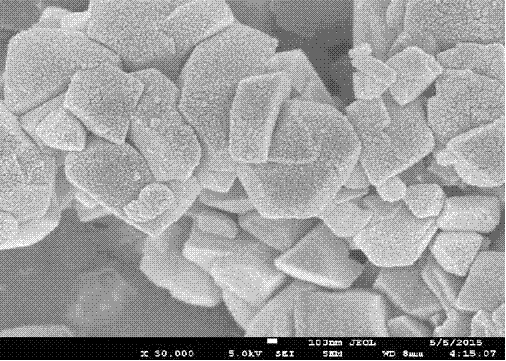

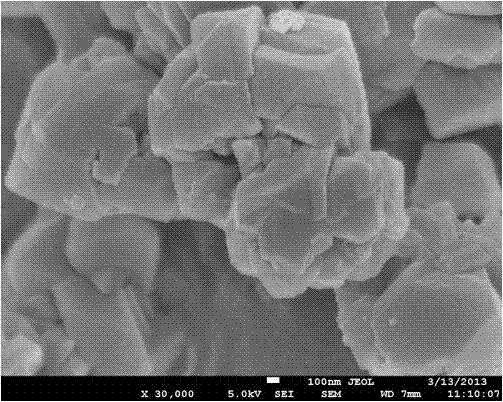

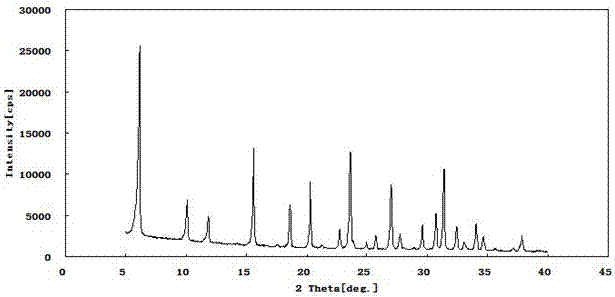

[0048] Take 278g of NaY raw powder and put it into 800mL of clean water, raise the temperature to 95°C, and start to add dropwise (NH 4 ) 2 SiF 6 Aqueous solution, 410mL solution concentration is 78g / L (NH 4 ) 2 SiF 6 solution, stirring at constant temperature for 2 hours after the dropwise addition, filtering and drying after the completion of the constant temperature, the dry basis of the dried molecular sieve is 63.8wt%; the above-mentioned dried molecular sieve is added to the hydrothermal treatment device, under gauge pressure 0.15MPa, temperature Under the conditions of 530°C and a treatment time of 1.5 hours, the molecular sieve was hydrothermally treated; 130g of the hydrothermally treated molecular sieve was put into 650mL of tetraethylammonium hydroxide aqueous solution with a mass concentration of 7.5%, and stirred at 80°C for 2 hours, then transfer the mixed material to a crystallization kettle for hydrothermal crystallization, the crystallization temperature i...

Embodiment 2

[0050] Take 278g of NaY raw powder and put it into 800mL of clean water, raise the temperature to 100°C, and start to add dropwise (NH 4 ) 2 SiF 6 Aqueous solution, 256mL solution concentration is 58g / L (NH 4 ) 2 SiF 6 solution, stirring at constant temperature for 2 hours after the dropwise addition, filtering and drying after the completion of the constant temperature, the dry basis of the dried molecular sieve is 65.0wt%; the above-mentioned dried molecular sieve is added to the hydrothermal treatment device, under gauge pressure 0.10MPa, temperature Under the conditions of 450°C and treatment time of 2.0 hours, the molecular sieve was hydrothermally treated; 130g of the hydrothermally treated molecular sieve was put into 369mL of tetraethylammonium hydroxide aqueous solution with a mass concentration of 4.8%, and stirred at a constant temperature of 85°C for 2 hours , and then transfer the mixed material to a crystallization kettle for hydrothermal crystallization, the...

Embodiment 3

[0052] Take 278g of NaY raw powder and put it into 800mL of clean water, raise the temperature to 95°C, and start to add dropwise (NH 4 ) 2 SiF 6 Aqueous solution, 410mL solution concentration is 78g / L (NH 4 ) 2 SiF 6 solution, stirring at constant temperature for 2 hours after the dropwise addition, filtering and drying after the completion of the constant temperature, the dry basis of the dried molecular sieve is 63.8wt%; the above-mentioned dried molecular sieve is added to the hydrothermal treatment device, under gauge pressure 0.15MPa, temperature Under the conditions of 480°C and treatment time of 1.0 hour, the molecular sieve was hydrothermally treated; 130g of the hydrothermally treated molecular sieve was put into 520mL of tetraethylammonium hydroxide aqueous solution with a mass concentration of 5.3%, and stirred at 80°C for 4 hours , and then transfer the mixed material to a crystallization tank for hydrothermal crystallization, the crystallization temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com