A kind of modified y/zsm-48 composite molecular sieve and its preparation method and application

A technology of ZSM-48 and composite molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of reducing the content of linear alkanes, good catalytic activity and diffusion performance, and favorable ring-opening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

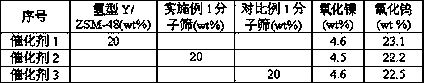

Embodiment 1

[0032] (1) Roast the Y-type molecular sieve at 550°C for 4 hours, and then completely impregnate the roasted Y-type molecular sieve in liquid C under the condition of 0.3MPa 10 h 18 in a nitrogen atmosphere for 2 hours, and then roasted at 500°C for 2 hours to carry out the carbon deposition reaction, and then put the Y-type molecular sieve after the carbon deposition in a 0.50mol / L sodium hydroxide solution (the amount of the molecular sieve added and the solution The mass ratio of medium water is 1:8) and treated at 70°C for 2.0 hours, and washed until the pH value is less than 10 to obtain a modified Y-type molecular sieve;

[0033] (2) Add the modified Y-type molecular sieve powder into the solution containing sodium hydroxide and hexamethyldiammonium bromide, age at 80°C for 3 hours under airtight conditions, add white carbon black, and continue to stir to obtain the reaction mixture. Glue system, the reaction mixture was crystallized at 170°C for 3 days under airtight c...

Embodiment 2

[0036] (1) Roast the Y-type molecular sieve at 450°C for 6 hours, and then completely impregnate the roasted Y-type molecular sieve in liquid C under the condition of 0.4MPa 8 h 14 in a nitrogen atmosphere for 1 hour, and then roasted at 550°C for 2 hours in a nitrogen atmosphere to carry out the carbon deposition reaction, and then put the Y-type molecular sieve after the carbon deposition in a 0.80mol / L sodium hydroxide solution (the amount of molecular sieve added and the solution The mass ratio of reclaimed water is 1:15) and treated at 80°C for 1.5 hours, and washed until the pH value is less than 10 to obtain a modified Y-type molecular sieve;

[0037] (2) Add the modified Y-type molecular sieve powder into the solution containing sodium hydroxide and hexamethyldiammonium chloride, age at 120°C for 1.0 hour under airtight conditions, add white carbon black, and continue to stir to obtain the reaction mixture. Glue system, the reaction mixture was crystallized at 160°C f...

Embodiment 3

[0040] Steps (1) and (2) are the same as in Example 1.

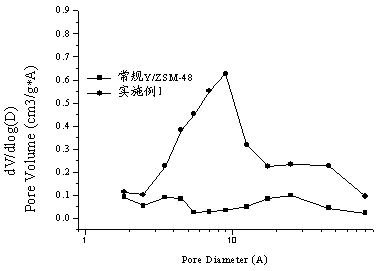

[0041](3) Under stirring conditions, mix the hydrogen-type Y / ZSM-48 composite molecular sieve and tetraethylammonium hydroxide solution in a high-pressure reactor, feed nitrogen to control the system pressure at 0.25MPa, and then raise the temperature to 70°C, Continue stirring at constant temperature for 3 hours, release the pressure, cool, filter with suction until the pH value is less than 9, dry at 100°C for 24 hours, and roast at 520°C for 6 hours to obtain a modified Y / ZSM-48 composite molecular sieve. The concentration of tetraethylammonium hydroxide solution is 0.10mol / L, and the mass ratio of hydrogen Y / ZSM-48 composite molecular sieve to water in the solution is 1:10. The specific properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com