Preparation process for praseodymium- iron- co-doped strontium titanate multiferroic film

A preparation process, the technology of strontium titanate, applied in the field of preparation of multiferroic thin films, can solve the problems of high cost, low phase transition temperature, and difficult synthesis, and achieve low cost, improved uniformity and density, and a preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

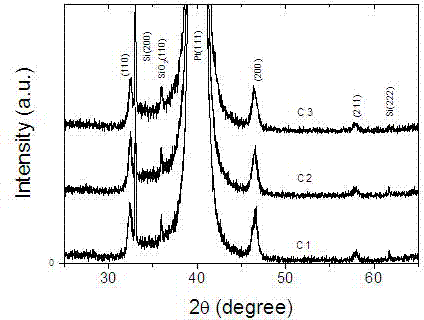

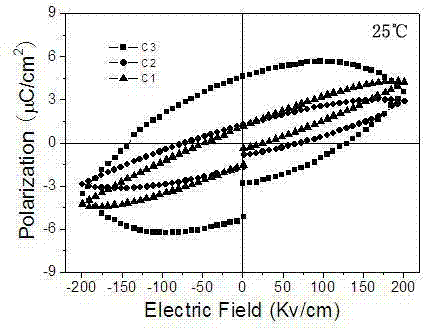

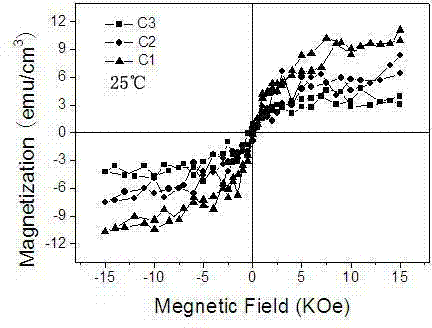

Embodiment 1

[0023] A preparation process of strontium titanate multiferroic film co-doped with praseodymium and iron, comprising the following steps:

[0024] Step 1. Weigh 0.0039078 mol of strontium acetate and 0.0000167 mol of praseodymium oxide (Pr 6 o 11 ), the molar ratio of strontium and praseodymium is Sr / Pr=0.975 / 0.025; 0.036 mol of butyl titanate and 0.004 mol of ferric nitrate are weighed in molar ratio, and the molar ratio of titanium and iron is Ti / Fe=0.9 / 0.1, standby;

[0025] Step 2. Dissolve all the strontium acetate weighed in step 1 in acetic acid to form a transparent and colorless solution, wherein the ratio of the volume of acetic acid added to the total weight of strontium acetate is 4mL: 1g, and then add ethylene glycol methyl ether, Make the molar concentration of strontium acetate in the solution reach 0.6mol / L, stir for 30 minutes, then add the butyl titanate weighed in step 1, stir for 30 minutes to form solution A, and set aside;

[0026] Step 3. Dissolve al...

Embodiment 2

[0030] A preparation process of strontium titanate multiferroic film co-doped with praseodymium and iron, comprising the following steps:

[0031] Step 1. Weigh 0.0039078 mol of strontium acetate and 0.0000167 mol of praseodymium oxide (Pr 6 o 11 ), the molar ratio of strontium and praseodymium is Sr / Pr=0.975 / 0.025; 0.032 mol of butyl titanate and 0.008 mol of ferric nitrate are weighed in molar ratio, and the molar ratio of titanium and iron is Ti / Fe=0.8 / 0.2, standby;

[0032] Step 2. Dissolve all the strontium acetate weighed in step 1 in acetic acid to form a transparent and colorless solution, wherein the ratio of the volume of acetic acid added to the total weight of strontium acetate is 4mL: 1g, and then add ethylene glycol methyl ether, Make the molar concentration of strontium acetate in the solution reach 0.6mol / L, stir for 30 minutes, then add the butyl titanate weighed in step 1, stir for 30 minutes to form solution A, and set aside;

[0033] Step 3. Dissolve al...

Embodiment 3

[0037] A preparation process of strontium titanate multiferroic film co-doped with praseodymium and iron, comprising the following steps:

[0038] Step 1. Weigh 0.0039078 mol of strontium acetate and 0.0000167 mol of praseodymium oxide (Pr 6 o 11 ), the molar ratio of strontium and praseodymium is Sr / Pr=0.975 / 0.025; 0.028 mol of butyl titanate and 0.012 mol of ferric nitrate are weighed in molar ratio, and the molar ratio of titanium and iron is Ti / Fe=0.7 / 0.3, standby;

[0039] Step 2. Dissolve all the strontium acetate weighed in step 1 in acetic acid to form a transparent and colorless solution, wherein the ratio of the volume of acetic acid added to the total weight of strontium acetate is 4mL: 1g, and then add ethylene glycol methyl ether, Stir for 35 minutes, then add the butyl titanate weighed in step 1, stir for 35 minutes to form solution A, set aside;

[0040] Step 3. Dissolve all the ferric nitrate weighed in step 1 in ethylene glycol methyl ether to form a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com