Circulation Pump System for Precision Roller Machining

A technology of roller processing and circulating pump, applied in the directions of transportation, packaging, conveyors, etc., can solve the problems of roller failure, roller pinching, easy material jamming, etc., and achieve the effect of convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

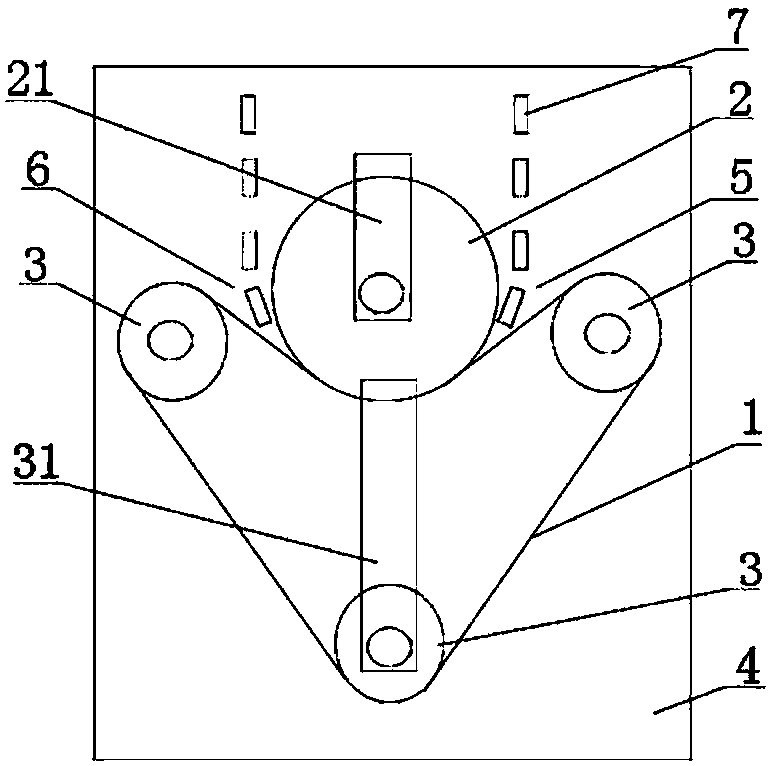

[0010] Refer to attached figure 1 , a circulating pump system for precision roller processing, which includes a conveyor belt 1, a driving wheel 2, a runner 3, a fixed plate 4, a driving wheel 2 rotates at the middle position on one side of the fixed plate 4, and the two sides of the driving wheel 2 are respectively A runner 3 is installed, and the lower side of the driving wheel 2 is also equipped with a runner 3. The conveyor belt 1 is bypassed from the lower end of the driving wheel 2, then from the runner 3 on one side, and then from the bottom of the runner 3 below. Over, finally go around from the runner 3 on the other side and get back to the drive wheel 2 below. The driving wheel 2 presses down the conveyor belt, and the conveyor belt 1 between the runners 3 on the left and right sides becomes an arc shape.

[0011] The driving wheel 2 presses on the conveyor belt 1 , a feed opening 5 is formed between one side of the driving wheel 2 and the conveyor belt 1 , and a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com