Automatic water adding control device and method for pelletizing pellets

A technology for automatic water addition and control devices, which is applied in the direction of program control, electrical program control, general control system, etc., can solve the problems that the drip water and atomized water cannot be adjusted separately, and the real-time value fluctuates greatly, so as to reduce energy consumption and improve productivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will now be described in further detail.

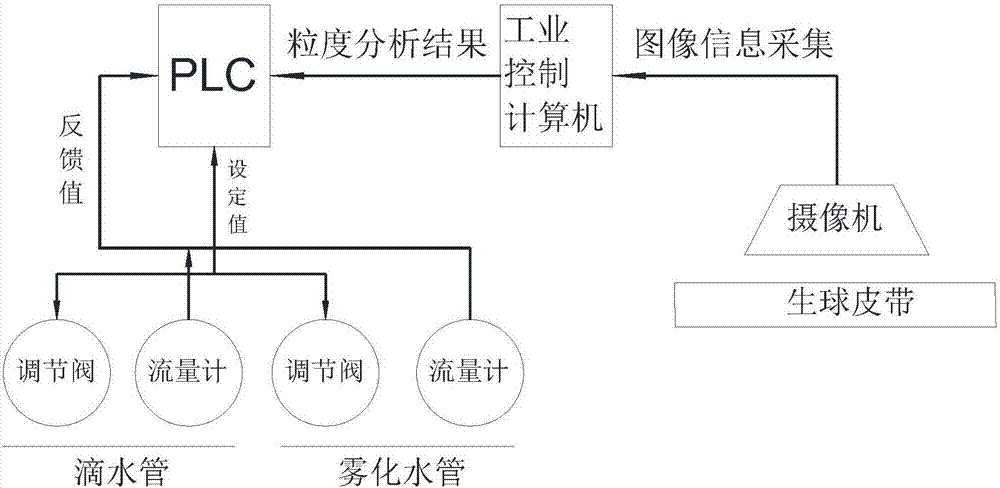

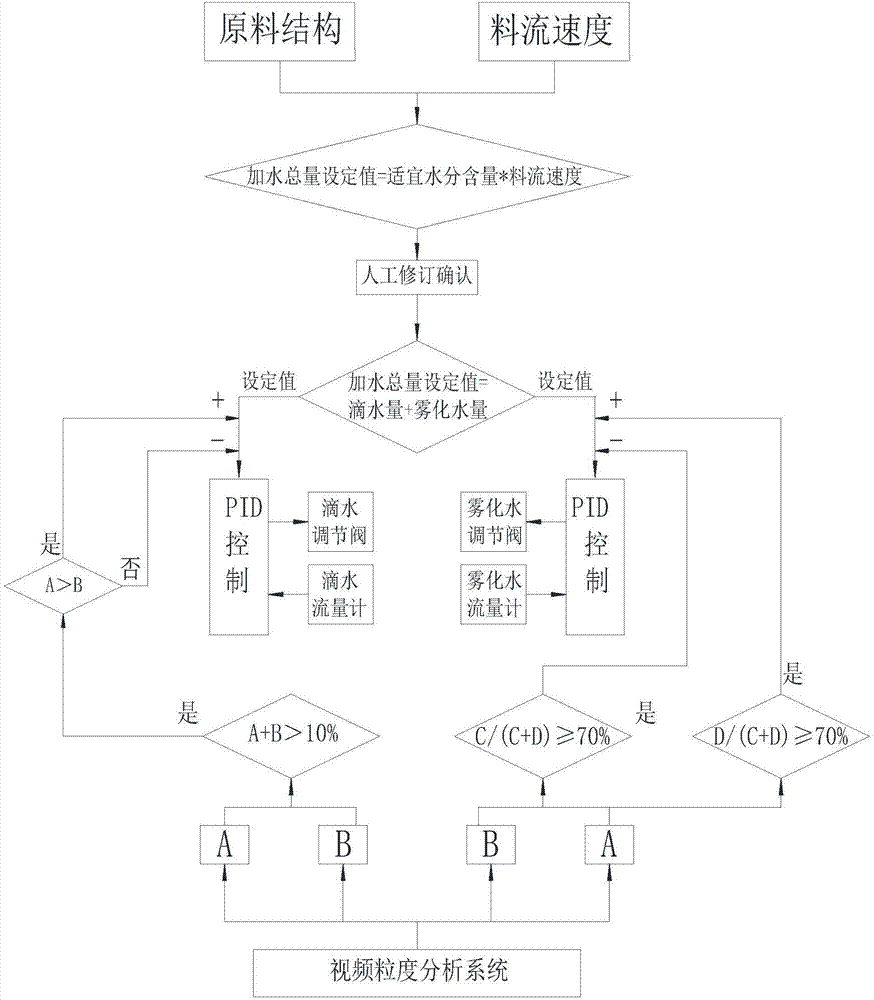

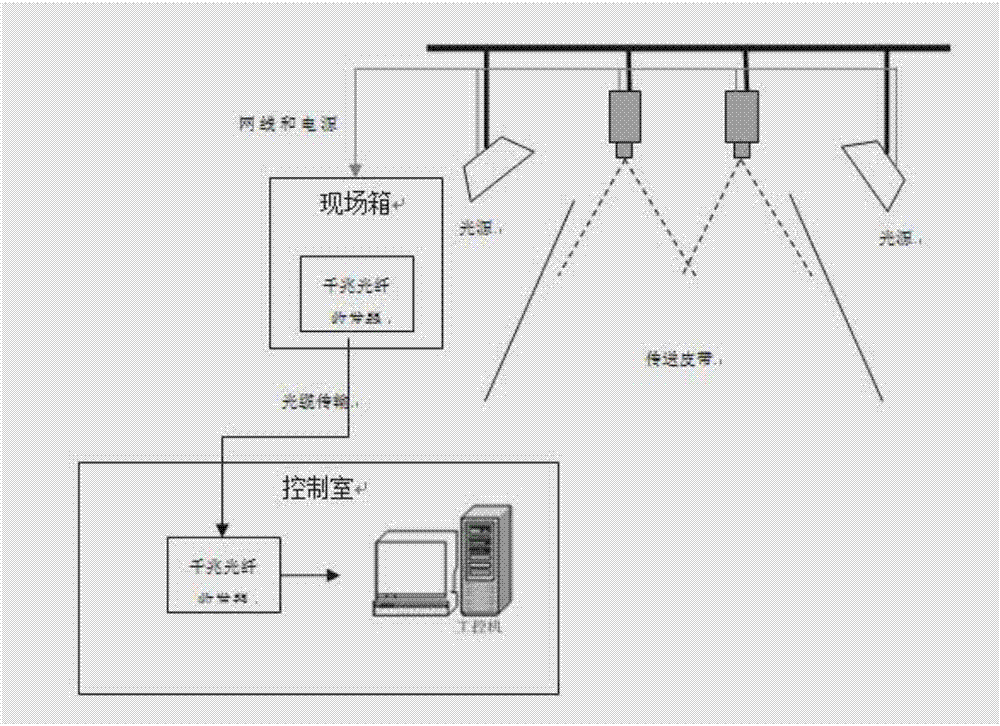

[0018] Such as figure 1 The shown automatic water addition control device for pelletizing pellets includes a raw pellet belt, a video particle size analysis system, a drip tube, and an atomizing tube. The drip tube is provided with a drip tube regulating valve and a drip tube flowmeter. The atomizing tube is provided with an atomizing tube regulating valve and an atomizing tube flowmeter. The video particle size analysis system adopts STV7800 of Tianjin Sante. The video particle size analysis system includes a camera and an industrial control computer (also known as an industrial computer). The camera is installed above the raw ball belt, the camera is connected with the industrial control computer through the data transmission device, and the image signal is transmitted to the industrial control computer, and the industrial control computer is connected with the input end of the PLC, and the input end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com