Plastic product qualification detection device

A product and plastic technology, which is applied in the field of plastic product testing equipment, can solve the problems of high labor intensity, high testing cost, and low testing accuracy, and achieve the effects of easy analysis and comparison, high detection accuracy, and improved detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

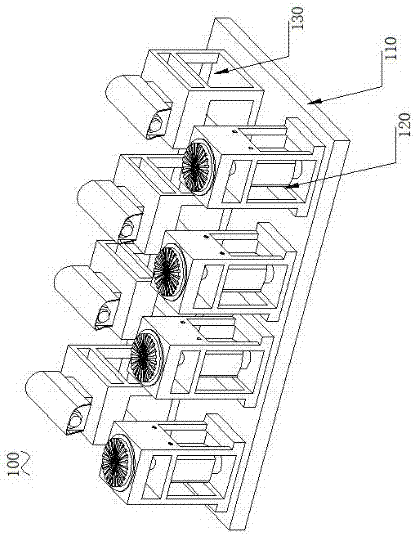

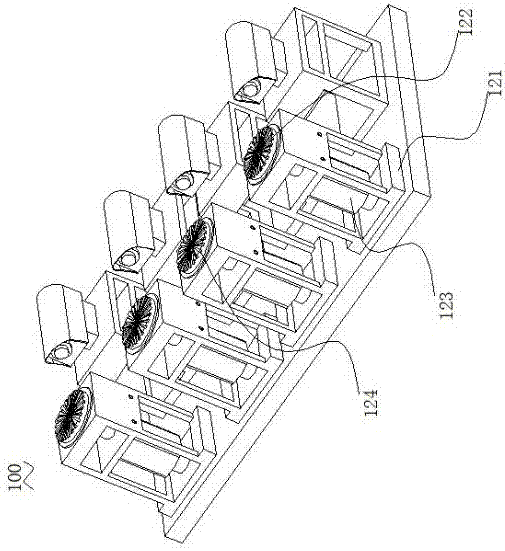

[0020] Such as figure 1 and figure 2 Shown are respectively perspective views of different viewing angles of the present invention.

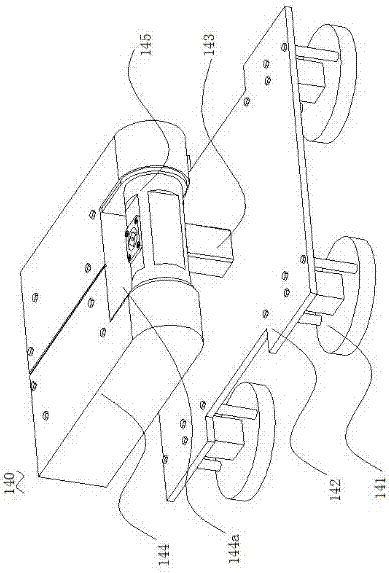

[0021] The qualified plastic product inspection device 100 includes a detection platform 110, a plurality of support bases 120 installed on the detection platform 110 for placing plastic products to be tested, a detection unit 130 installed on the detection platform 110 and opposite to the support base 120, and It includes a transfer manipulator 140 located above the inspection platform 110 for transferring the plastic product to be inspected to the support base 120 and a control unit (not shown) electrically connected to the inspection unit 130 for controlling the inspection unit 130 .

[0022] Several support bases 120 and several detection units 130 are all arranged in a straight line, and the straight line formed by several suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com