Multi-target integrated scheduling method for multi-place transportation in cloud manufacturing environment

A scheduling method and cloud manufacturing technology, applied in the direction of instruments, data processing applications, resources, etc., to achieve the effect of increasing diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

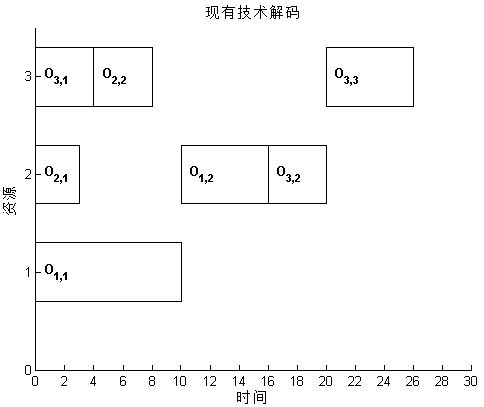

[0028] A multi-location and multi-objective comprehensive scheduling method in a cloud manufacturing environment has been widely used in practical applications. attached figure 1 It is an example of the application of the method of the present invention to a hydroelectric generator. Each component of a large generator is jointly manufactured by multiple enterprises, and finally assembled and processed by the headquarters. In the process of processing, it needs to be transported between different enterprises through logistics. The transportation factor brings greater difficulty to the manufacture of the entire scheduling plan, and the invention can ensure that the user provides the optimal scheduling plan under the specified time, cost and quality conditions.

Embodiment 2

[0030] A multi-location and multi-objective comprehensive scheduling method in a cloud manufacturing environment. Its application scenario is: the manufacturing resources of multiple enterprises in the cloud manufacturing platform can provide corresponding processing services. The system will evaluate the service quality of manufacturing resources according to the on-time delivery rate, service reliability and other indicators of different manufacturing resources. Each manufacturing resource will also be evaluated by the user after use. Users can set according to their own requirements for time, cost, service quality and satisfaction, and the scheduling system needs to help operators arrange scheduling plans according to users' personalized goals. The decentralization of manufacturing resources makes the workpiece need to be transported multiple times to complete the overall processing, and the different manufacturing resources selected for each task lead to different transport...

Embodiment 3

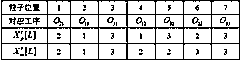

[0032] A multi-location and multi-objective comprehensive scheduling method in a cloud manufacturing environment, which is characterized in that: firstly, a two-layer coding method based on procedures and resources is adopted, the first layer of coding represents the process, and the second layer of coding is used to represent each process The resources used; the individual population is generated randomly; the first step in the evolution is to randomly select an element in the first layer of the individual, and exchange the positions of the adjacent elements, and the corresponding processing resources will also exchange positions. Two positions are randomly selected in the second-level individuals, and two are randomly selected in the optional resource set for changing positions to replace; the second step randomly divides the process into two sets and generates a new individual, which is contained in the individual The processes and resources in the first set and the processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com