Potato quick nondestructive testing and automatic grading device and method

A non-destructive testing and automatic grading technology, applied in sorting, application, food processing, etc., can solve the problems of wrong grading of potatoes, inability to judge the size and shape of potatoes, failure to realize intelligent grading of potatoes, etc., and achieve the goal of non-destructive testing and grading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

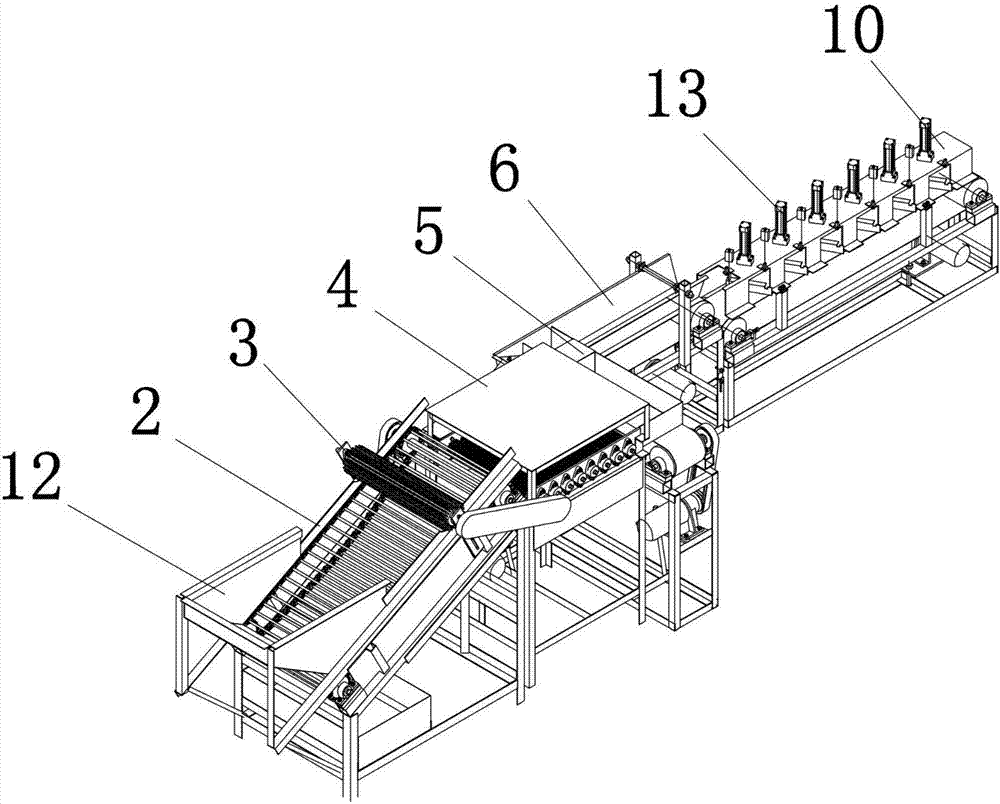

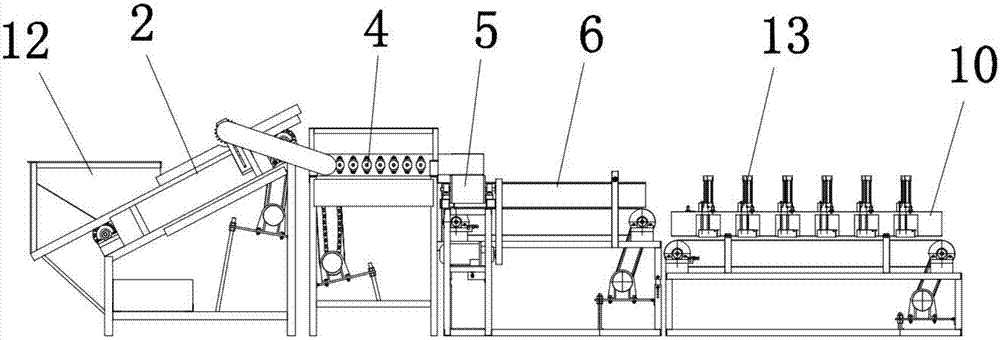

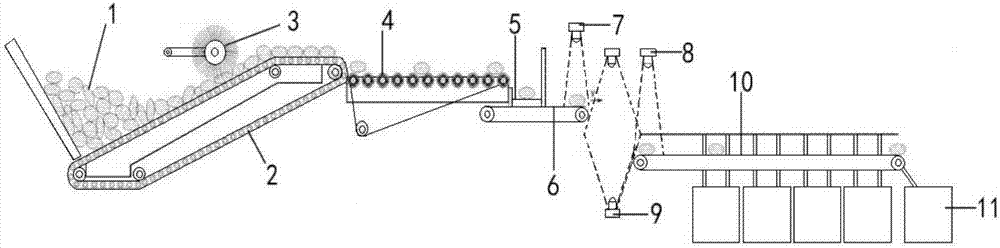

[0027] Such as Figure 1-5 As shown, the automatic grading device in the present invention comprises a climbing roller conveying device 2, a transverse conveying belt 5, a longitudinal conveying belt 6, and a classification output device 10; An included angle of 20-60°; a chain conveyor belt is set on the climbing roller conveying device 2; a feeding hopper 12 is vertically arranged on the lower inclination angle of the chain conveyor belt, and a roller brush 3 is arranged in parallel on the upper inclination angle;

[0028] The rear end of the climbing roller conveying device 2 is connected with the soil removing conveying device 4; the soil removing conveying device 4 is provided with a plurality of roller brushes in parallel for cleaning and orderly arranging the transferred potatoes; The rear end of the soil removal conveying dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com