Conveying mechanism used for cylinder side face defect visual inspection

A technology of visual inspection and conveying mechanism, which is used in measuring devices, material analysis by optical means, instruments, etc., to achieve the effect of reducing consumption and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

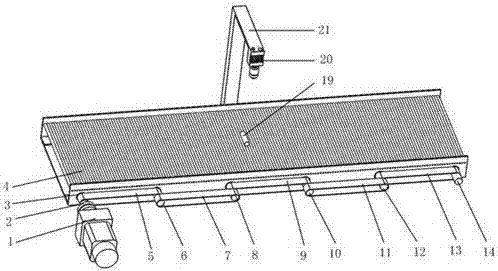

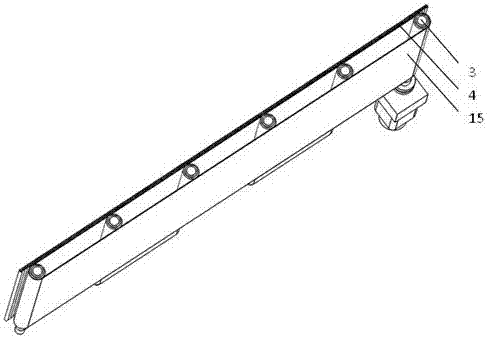

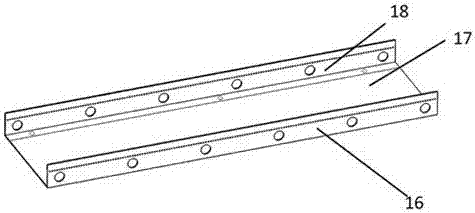

[0021] A transmission mechanism for visual detection of defects on the side of a cylinder, the first frame side plate 16 and the second frame side plate 18 are fixed on the frame base 17 . The power shaft one 3 is connected with the output shaft of the motor 1 through a shaft coupling 2 .

[0022] The transmission roller 4 is installed on the frame side plate one 16 and the frame side plate two 18 correspondingly, and the transmission roller 4 can rotate freely around the axis. The friction belt 15 is installed on the power shaft one 3 and the power shaft six 14, the friction belt 15 is in contact with the transmission roller 4, and the friction belt 15 drives the movement of the transmission roller 4 by friction.

[0023] Described power shaft one 3, power shaft two 6, power shaft three 8, power shaft four 10, power shaft five 12, power shaft six 14 are respectively installed on frame side plate one 16 and frame side plate two 18 by bearings corresponding position. Belt 1 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com