Automatic assembling device of switch cassette

An automatic assembly, cassette technology, applied in conveyor control devices, transportation and packaging, metal processing equipment, etc., can solve problems such as low installation efficiency and unstable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

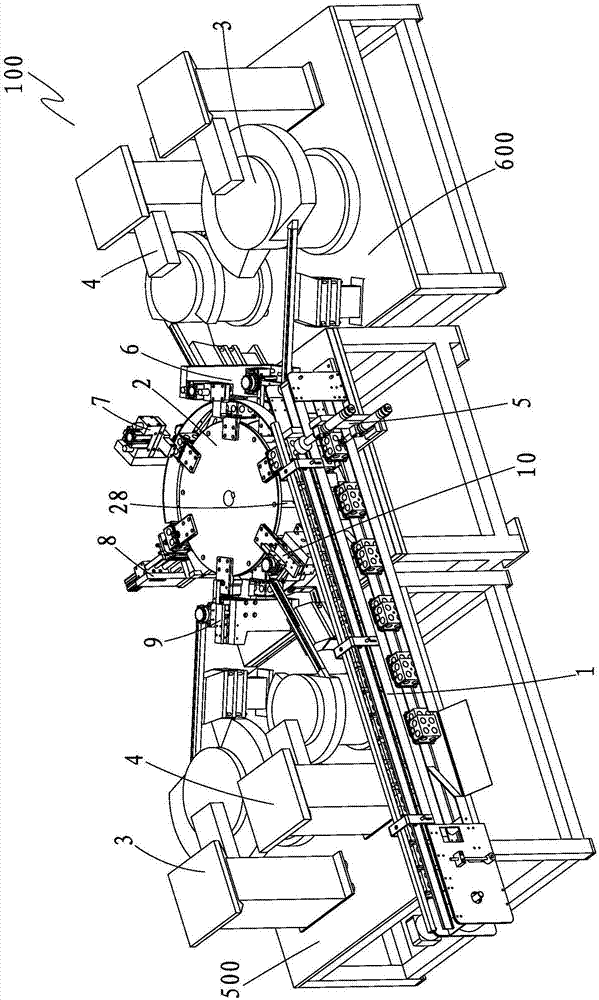

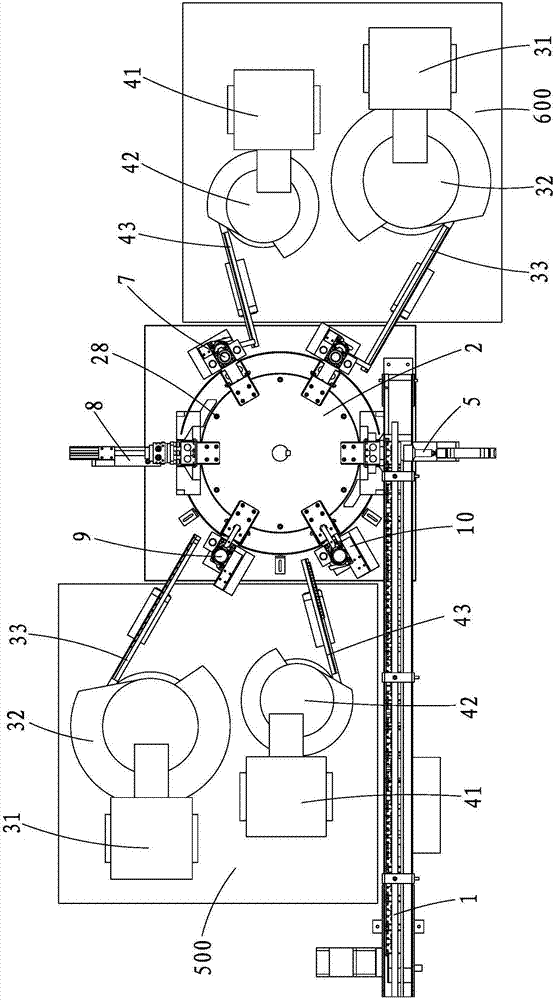

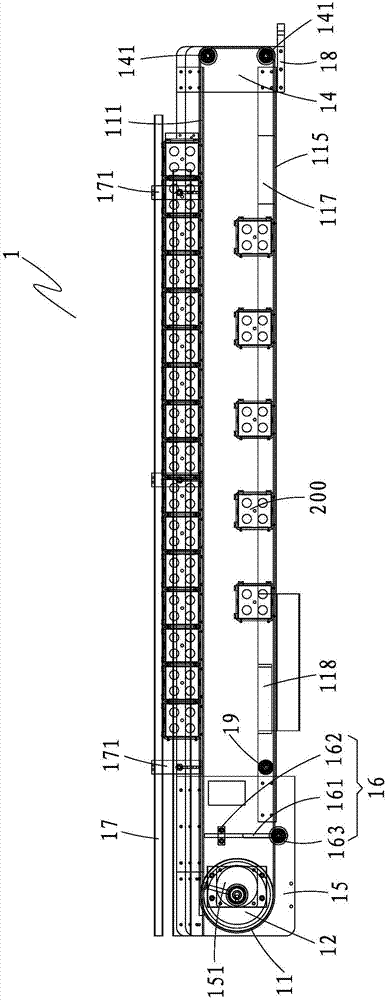

[0049] see Figure 1 to Figure 16 As shown, a preferred embodiment of a switch cassette automatic assembly device 1000 of the present invention, the automatic assembly device 1000 includes a double-layer box body conveying mechanism 1, a double-layer turntable mechanism 2, and two U-shaped piece feeding mechanisms 3 , two L-shaped parts feeding mechanisms 4 and a control device (not shown); the surrounding of the double-layer turntable mechanism 2 is provided with a set of loading and unloading mechanisms 5, a set of loading and unloading functions in one. A first pre-pressing pick-up mechanism 6 that integrates pre-pressing and U-shaped piece pick-up functions, a first compacting pick-up mechanism 7 that integrates compaction and L-shaped piece pick-up, and a box rotation mechanism 8 , a second pre-pressing and picking mechanism 9 integrating pre-pressing and U-shaped piece picking functions and a second pressing and picking-up mechanism 10 integrating pressing and L-shaped p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com