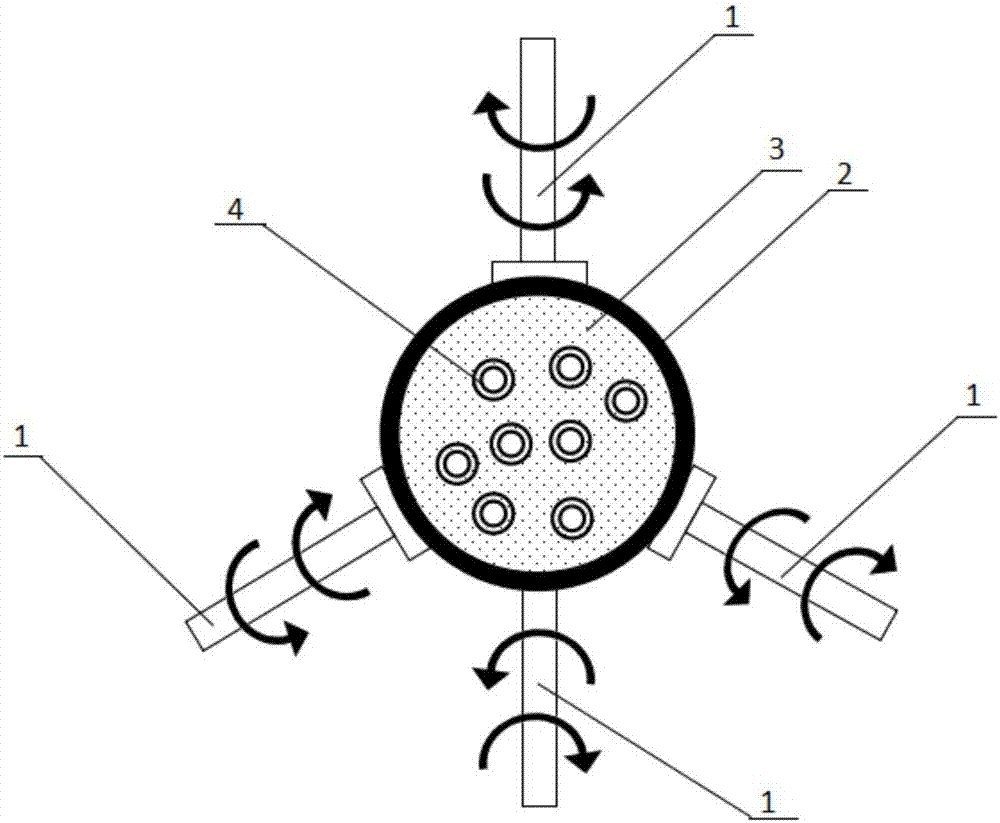

Method of preparing polymeric hollow microspheres by three-dimensional random flow field

A hollow microsphere and polymer technology, which is used in the field of polymer processing and molding, can solve the problems of uneven wall thickness, poor spheroidization of polymer hollow microspheres, and reduced mechanical properties, so as to improve sphericity and uniform wall thickness. properties, overcoming fixed orientation problems, reducing the effect of aspherical tendencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

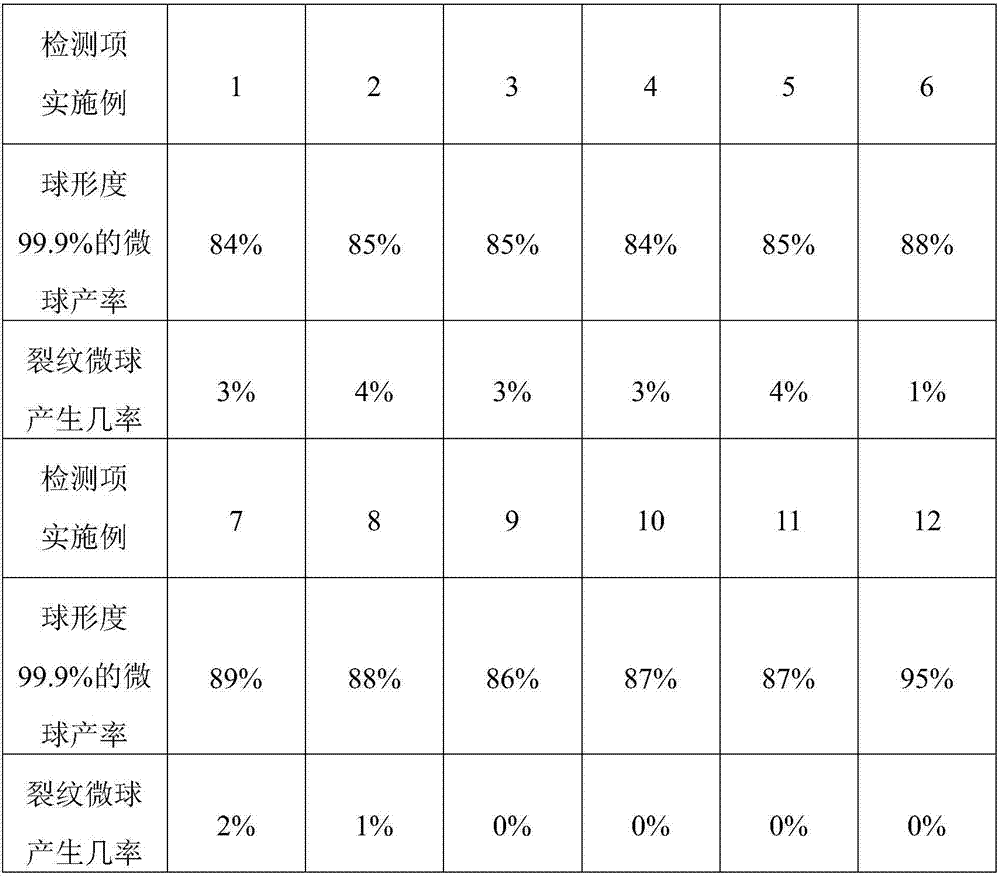

Examples

Embodiment 1

[0031] A method for preparing polymer hollow microspheres using a three-dimensional random flow field, comprising the following steps:

[0032] Step 1. Prepare 0.05wt% polyacrylic acid aqueous solution, filter it with a filter membrane of 5 μm, and obtain W2 external aqueous phase solution; process a hemispherical container with threads by using polytetrafluoroethylene material; add W2 external aqueous phase solution into the hemispherical container Middle; the size of the hemispherical container is 5cm in outer diameter, 3cm in inner diameter, and 1cm in wall thickness;

[0033] Step 2. Dissolve poly-α-methylstyrene in fluorobenzene to prepare a 12wt% O oil phase solution; use distilled water as the inner water phase of W1, and use microfluidic technology to generate W1 inner water phase / O oil phase / W2 outer phase Water phase double compound emulsion;

[0034]Step 3, using the hemispherical container equipped with the W2 external aqueous phase solution to collect the double ...

Embodiment 2

[0038] A method for preparing polymer hollow microspheres using a three-dimensional random flow field, comprising the following steps:

[0039] Step 1: prepare 1wt% polyacrylic acid aqueous solution, filter it with a filter membrane of 5 μm, and obtain W2 external aqueous phase solution; process a hemispherical container with threads by utilizing polytetrafluoroethylene material; add W2 external aqueous phase solution into the hemispherical container ; The size of the hemispherical container is that the outer diameter is 6cm, the inner diameter is 4cm, and the container wall thickness is 1cm;

[0040] Step 2. Dissolve polystyrene in toluene to prepare a 15wt% O oil phase solution; use distilled water as the inner water phase of W1, and use microfluidic technology to produce a double composite of W1 inner water phase / O oil phase / W2 outer water phase Milk grains;

[0041] Step 3, using the hemispherical container equipped with the W2 external aqueous phase solution to collect t...

Embodiment 3

[0045] A method for preparing polymer hollow microspheres using a three-dimensional random flow field, comprising the following steps:

[0046] Step 1, prepare 1.5wt% polyvinyl alcohol aqueous solution, filter with a filter membrane of 5 μm to obtain W2 external aqueous phase solution; use polytetrafluoromaterial to process threaded hemispherical container; add W2 external aqueous phase solution to hemispherical device;

[0047] Step 2. Dissolve deuterated polystyrene in 1,2-dichloroethane to prepare a 10wt% O oil phase solution; use distilled water as the internal water phase of W1, and use microfluidic technology to generate the internal water phase of W1 / O Oil phase / W2 external water phase double composite emulsion;

[0048] Step 3, using the hemispherical container equipped with the W2 external aqueous phase solution to collect the double composite emulsion, and tightening the two hemispherical containers through threads to form a spherical container that encapsulates the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com