Automatic flattening device for carding machine of electro-mechanical room

A self-leveling and chamber carding technology, applied in the field of carding machines, can solve the problems of inability to adjust the sliver, backflow of raw materials, poor separation effect, etc., and achieve the effects of reducing backflow of raw materials, high leveling efficiency and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

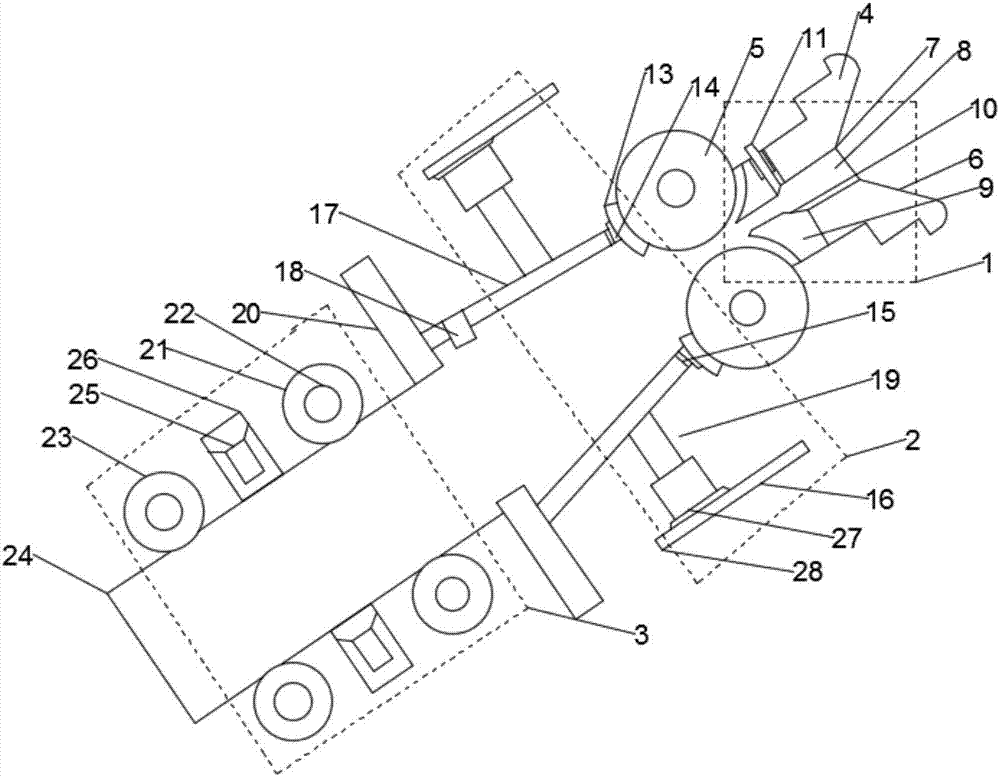

[0017] see figure 1 , the present invention provides a technical solution: an autoleveling device for a carding machine in an electromechanical chamber, including an air flow detection mechanism 1, a feeding mechanism 2 and a uniform device 3, and the feeding mechanism 1 includes a first horn seat 4, a second Two horn bases 6 and two pressing rollers 5, the first horn base 4 and the second horn base 6 adopt exactly the same structure, and a feeding material is arranged between the first horn base 4 and the second horn base 6 port 7, one end of the first horn base 4 and the second horn base 6 is connected with a feed trough 8, the air flow detection mechanism 1 is composed of two compression seats 9, the first horn base 4 and the second horn base The other end of 6 is connected with the compression seat 9, a bell mouth 10 is arranged between the compression seats 9, an airflow hole 11 is arranged on the side of the compression seat 9, and a pressure sensor 12 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com