A net-clamped side-pressing thickener

A technology of thickener and mesh, applied in pulp dewatering and other directions, can solve the problems of limited pulp level difference, slow sewage discharge, low coaxing pressure, etc., and achieve the effect of reducing mesh consumption, increasing service time, and increasing the rotation speed of mesh cages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

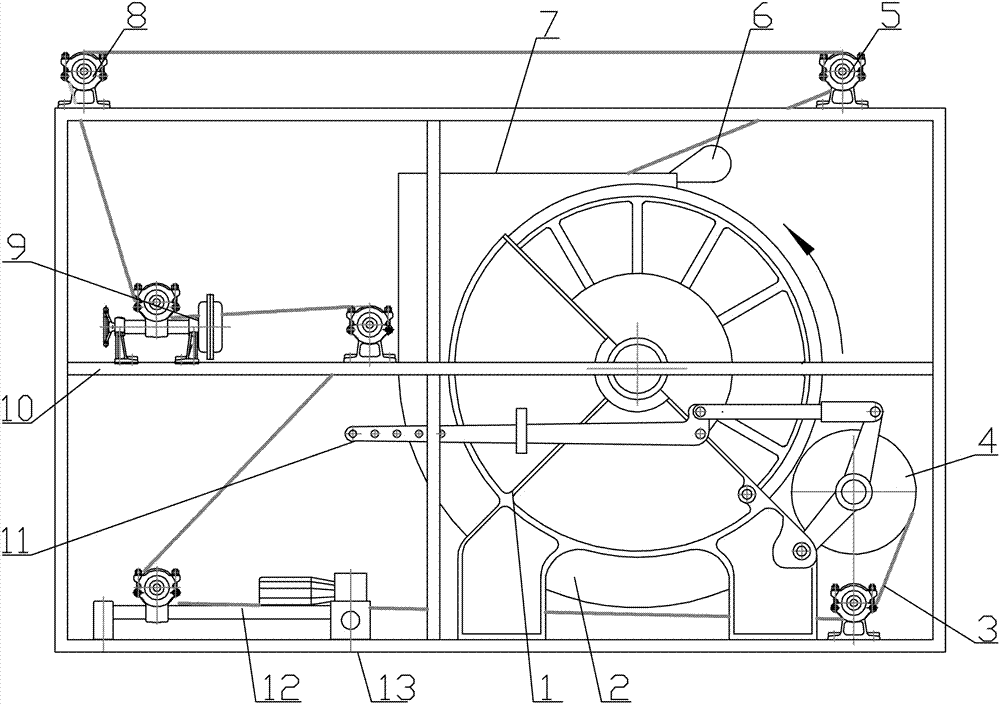

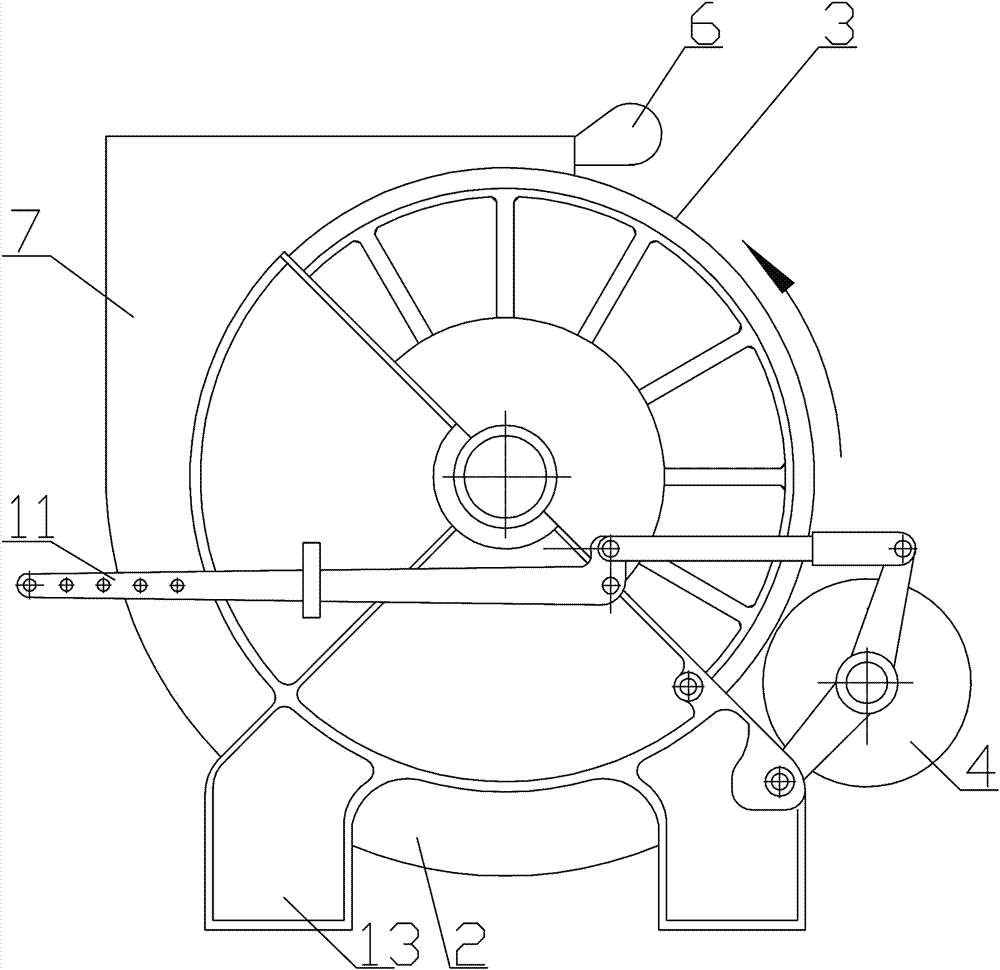

[0022] see Figure 1-2 , clamping net side pressure concentrator, it comprises frame 13, and the middle part of the right side of described frame 13 is equipped with mesh cage 1, and the outside of described mesh cage 1 is equipped with slurry groove 7, and the bottom of described mesh cage 1 is installed There is a sewage tank 2, and the sewage tank 2 is fixedly installed on the bottom of the frame 13, the outside of the cage 1 is equipped with a filter screen 3, the top of the slurry tank 7 is provided with a slurry inlet pipe 6, and the filter The net 3 cooperates with the outer surface of the cage 1 through the rubber roller 4 . Slurry can be injected into the slurry tank 7 through the slurry inlet pipe 6. After the slurry is sprayed on the cage 1, it is covered and squeezed in the middle by the filter screen, so that part of the sewage in the slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com