Method for generating noncontact measurement feature points

A non-contact measurement and feature point technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve problems such as measurement failure and increased complexity, and achieve the effects of improving measurement accuracy, wide applicability, and simple generation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

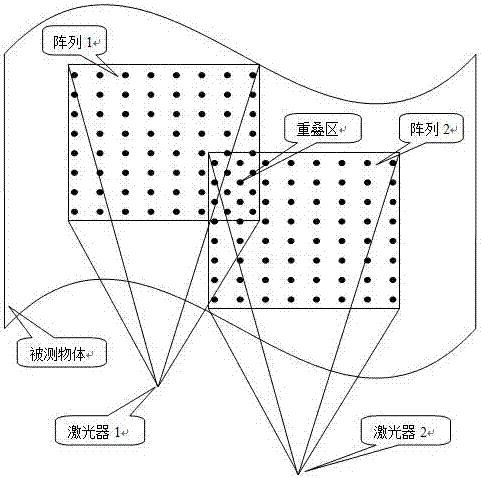

[0015] A method for generating feature points of non-contact measurement, characterized in that: the method is implemented by the following steps:

[0016] Step 1. Project the first set of laser spot arrays into the first measurement area on the surface of the object to be measured, and at the same time project the second set of laser spot arrays on the area adjacent to the first set of laser spot arrays to form two groups with approximate dimensions and The characteristic laser spot array, each laser spot is listed as a laser spot feature point, the first group of laser spot arrays and the second group of laser spot arrays in the first measurement area include three or more non-collinear Laser spot feature points;

[0017] Step 2. According to the difference in the distribution position of the laser spot, the difference in the size, shape and gray value of the image point on the laser spot image is brought, and the center of the feature point of the laser spot is extracted ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com