Preparation method of Pt3Ni@PtNi2 core-shell structure nanowire

A core-shell structure, nanowire technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of harsh reaction conditions, high cost of large-scale production, cumbersome imine steps, etc., and achieve high selectivity, high The generation method is simple and the catalytic effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Select 9mg of platinum acetylacetonate, 2mg of nickel acetylacetonate, 60mg of glucose, 30mg of cetyltrimethylammonium chloride and add 5mL of oleyl ammonia to dissolve; ultrasonicate the above solution in an ultrasonic machine for 1 hour until it is completely dissolved, and then dissolve the above solution Put it in an oil bath at 200° C. for 1 hour to react; wash and dry the reaction product with a mixed solvent of ethanol and n-hexane to obtain the nanowire.

Embodiment 2

[0029] Select 9mg of platinum acetylacetonate, 2mg of nickel acetylacetonate, 60mg of glucose, 30mg of cetyltrimethylammonium chloride and add 5mL of oleyl ammonia to dissolve; ultrasonicate the above solution in an ultrasonic machine for 1 hour until it is completely dissolved, and then dissolve the above solution Put it in an oil bath at 200° C. for 5 hours to react; wash and dry the reaction product with a mixed solvent of ethanol and n-hexane to obtain the nanowire.

Embodiment 3

[0031] Select 9mg of platinum acetylacetonate, 2mg of nickel acetylacetonate, 30mg of glucose, 30mg of cetyltrimethylammonium chloride and add 5mL of oleyl ammonia to dissolve; ultrasonicate the above solution in an ultrasonic machine for 1 hour until it is completely dissolved, and then dissolve the above solution Put it in an oil bath at 200° C. for 1 hour to react; wash and dry the reaction product with a mixed solvent of ethanol and n-hexane to obtain the nanowire.

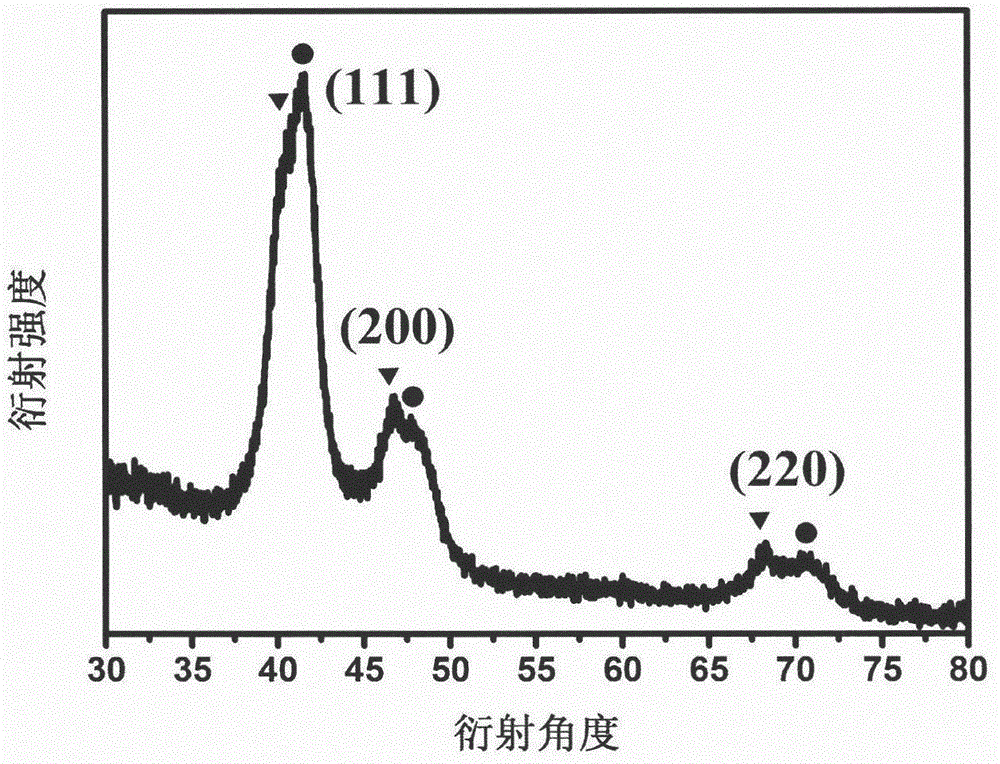

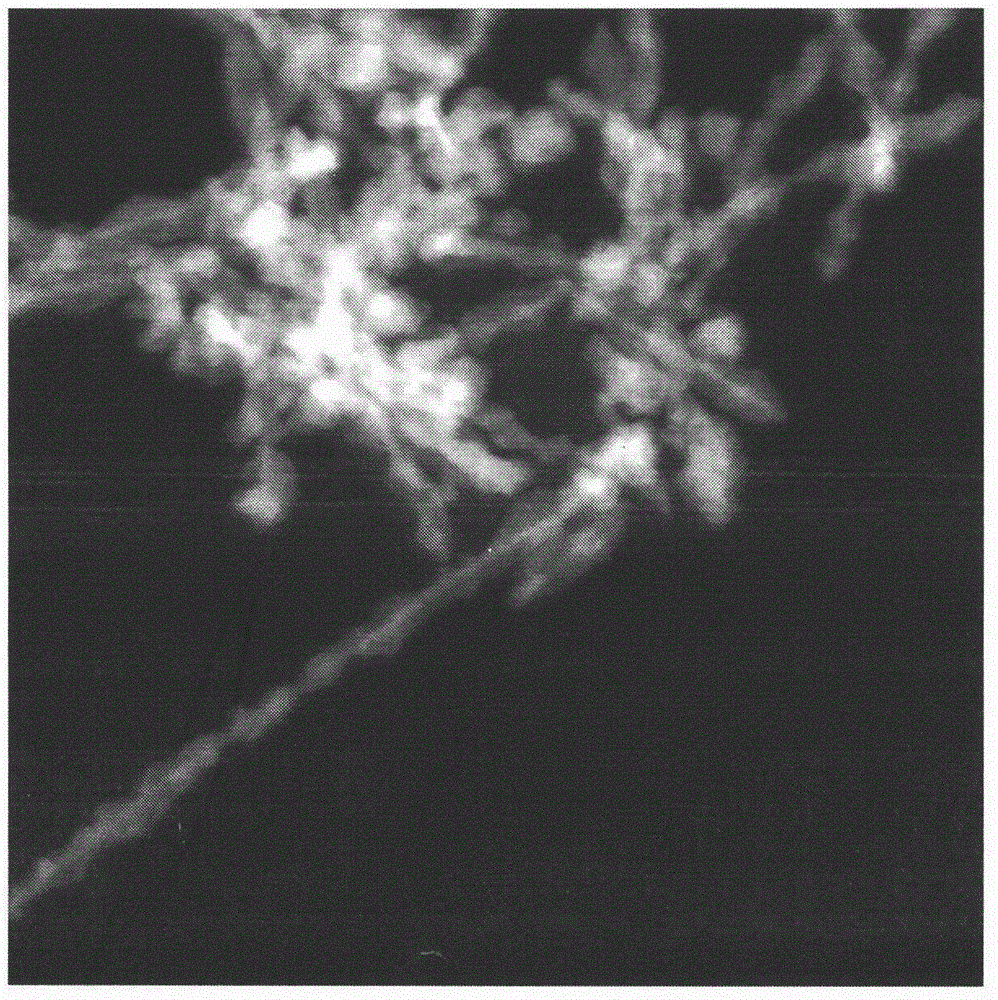

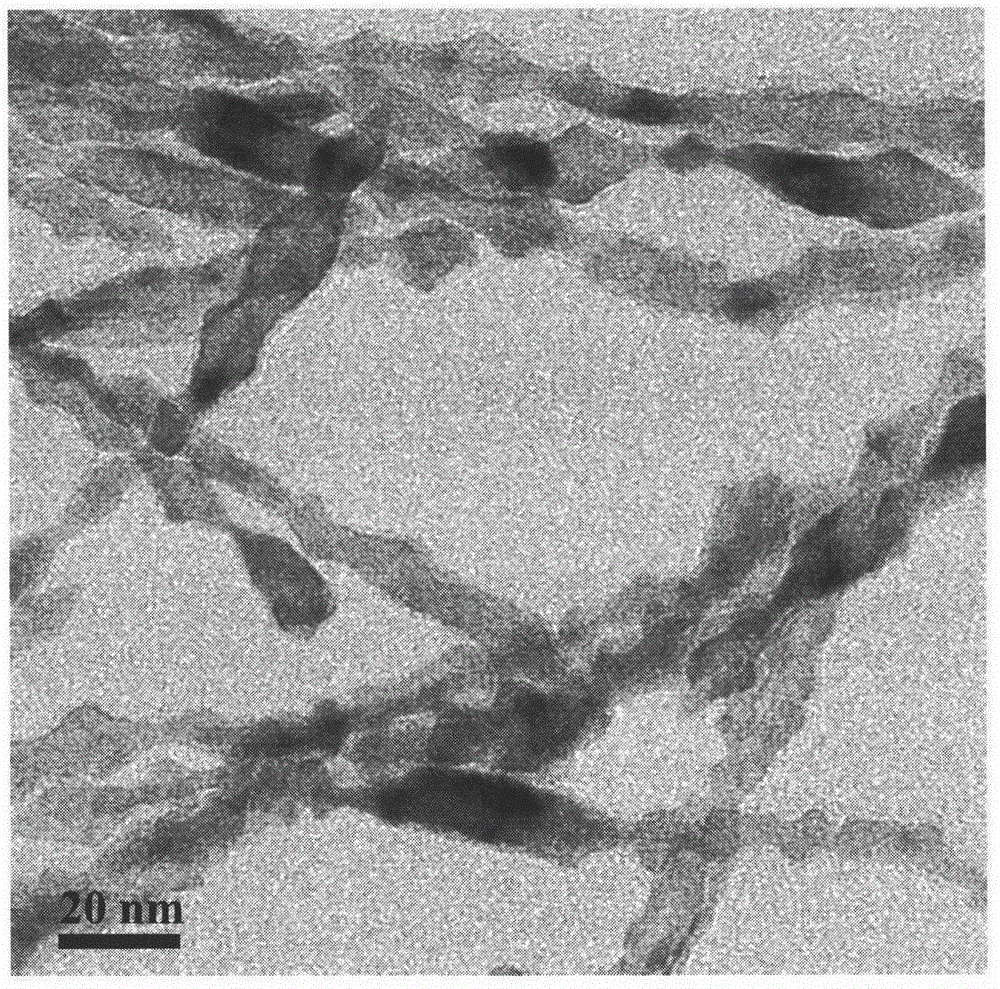

[0032] Such as figure 1 , figure 2 , image 3 As shown, using D8ADVANCE type XRD (Cu kαradiation, , German Bruker-AXS company) to determine the crystal phase structure of the prepared samples. The morphology of the prepared samples was observed by S4800II FESEM (FESEM, s-4800II, Hitachi). The Tecnai F30 field emission transmission electron microscope (HRTEM, Tecnai F30, FEI) from philips-FEI in the Netherlands was used to detect and characterize the structure of the samples intuitively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com