Sculpture model generating system and method, as well as sculpture model 3D printing system and method

A model generation and model technology, applied in the field of image processing, can solve problems such as complex structure of 3D models, increase the amount of extraction, prolong operation time, etc., achieve the effect of expanding image data types, reducing operation difficulty, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

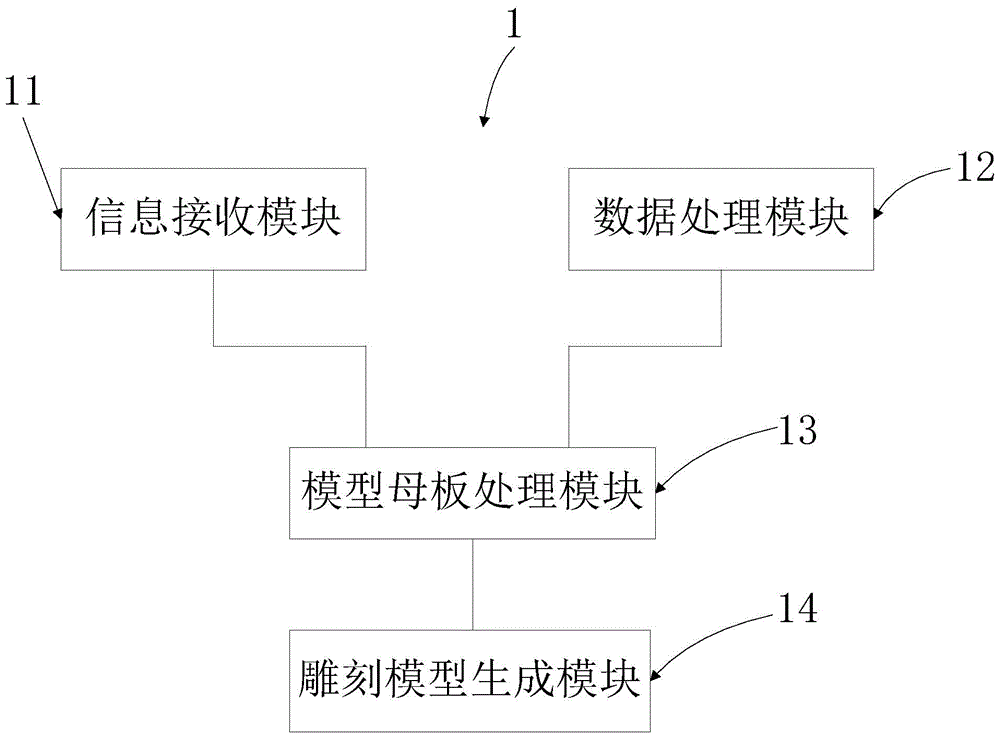

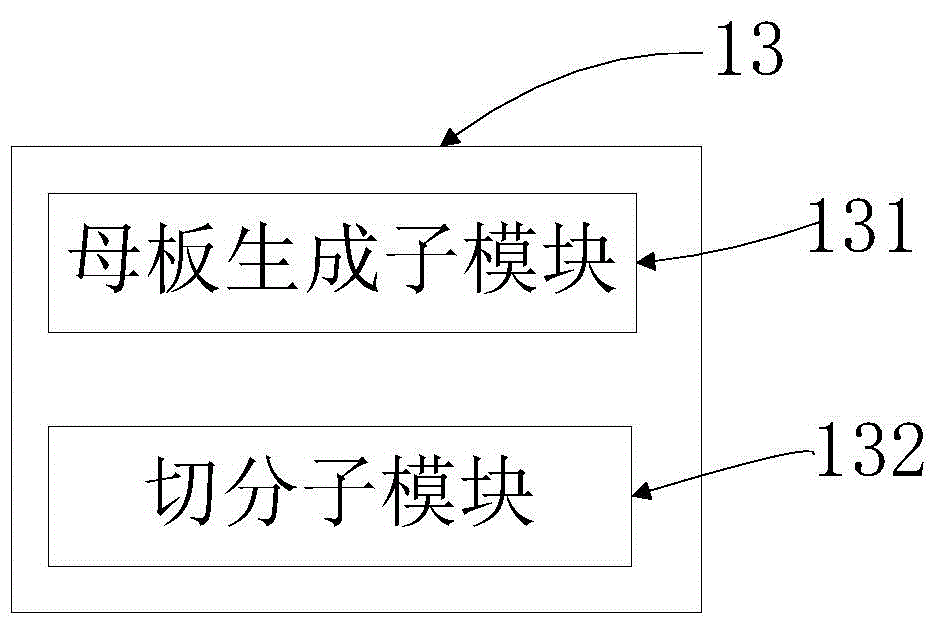

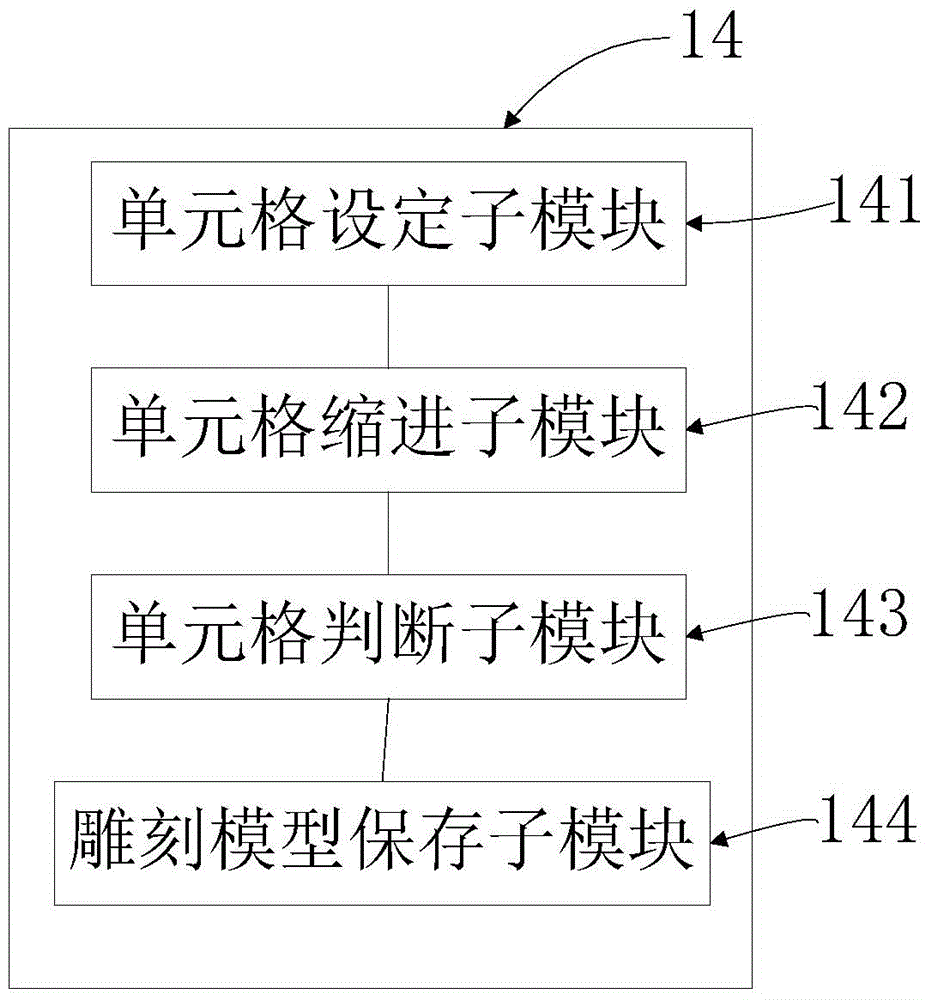

[0104] Such as figure 1 and Figure 16 As shown, this embodiment provides an engraving model generating system 1 , including: an information reading module 11 , a data processing module 12 , a model master processing module 13 and an engraving model generating module 14 .

[0105] Wherein, the information reading module 11 is used for reading the model configuration information of the sculpture model to be generated. Model configuration information is the information set by the user according to the design requirements of the engraving model. The model configuration information includes engraving model size information, engraving model color information, engraving model effect information, engraving model foreground information, engraving model background information and engraving model base plate information Wait. Wherein, the color information of the engraving model may be the color of the engraving model set by the user according to his / her preference. The engraving model ...

Embodiment 2

[0151] Such as Figure 9 and Figure 16 As shown, the structure of the engraving model generating system provided in this embodiment is basically the same as that of the engraving model generating system 1 provided in Embodiment 1, the difference is that the engraving model generating module 14 also includes a model coloring sub-module 147 . The model coloring sub-module 147 provided in this embodiment is used to colorize the sculpture model according to the color information of each pixel in the image data, specifically:

[0152] (1) Obtain the position and color information of each pixel in the image data;

[0153] (2) Determine the corresponding cell 21 in the engraving model according to the pixel position information;

[0154] (3) Assign the color information of the pixel points in (1) to the cell 21, associate the color information with the corresponding cell 21, that is, complete the coloring process of the engraving model.

[0155] The engraving model generated afte...

Embodiment 3

[0158] Such as Figure 10 and Figure 16 As shown, the engraving model generating system provided in this embodiment is basically the same in structure as the engraving model generating system 1 provided in Embodiment 1 and Embodiment 2, the difference is that the model master processing module 13 also includes a frame generating sub-module 133 . The model configuration information also includes border setting information, and the border generation sub-module 133 is used to generate a border on the outer edge of the model motherboard 2 according to the border setting information. The border can be set according to the user's own needs, enriching the appearance of the engraving model.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com