A v-cut surface treatment process for side-adhesive light guide plates

A technology of surface treatment and light guide plate, applied in the field of light guide plate, can solve the problems of limited brightness, high cost, and difficult molding of light guide plate, and achieve the effect of avoiding white spots, avoiding changes, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

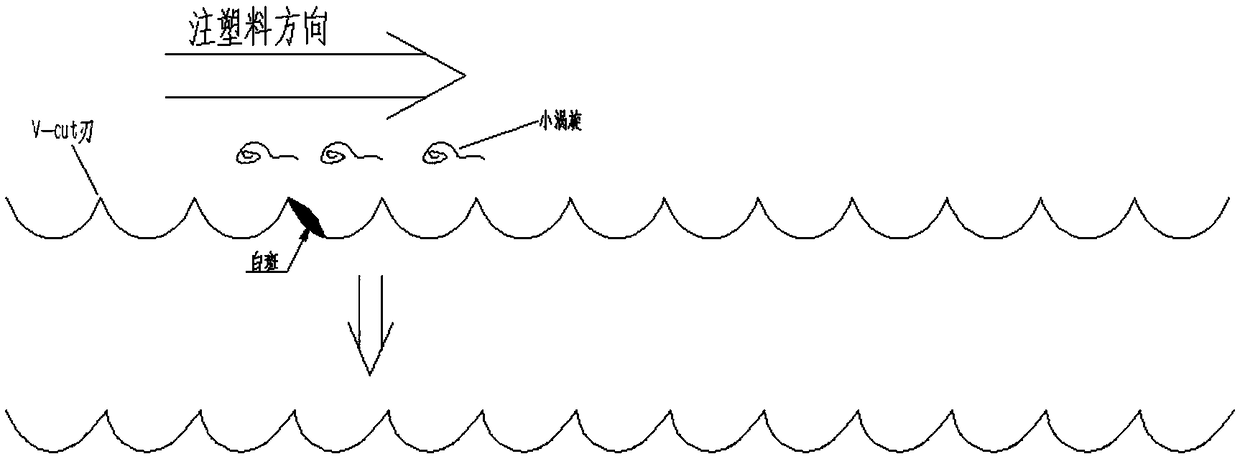

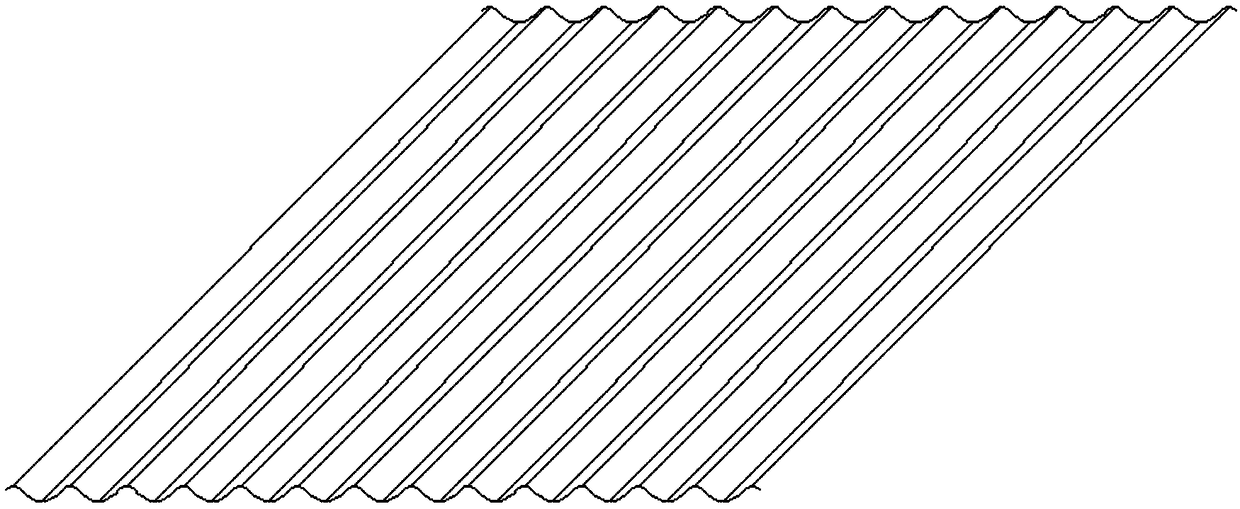

[0030] Please refer to Figure 2 to Figure 5 , because the existence of the V-cut edge causes white spots, so it is considered to remove the edge and make the original V-cut edge into an arc structure, so that the V-cut groove can be made as figure 2 and image 3 The form of the double arc surface shown can solve the problem of white spot. If you want to remove the V-cut edge, the most direct way is to make another knife with a concave radian, but it is difficult to process this kind of knife, and the cost of realization is too high, and some such as Figure 4 The special or complex V-cut groove shown in the figure should be processed into such Figure 5 The style shown cannot be achieved in this way.

[0031] Please refer to Figure 6 as well as Figure 7 , the present invention draws lessons from the method for hole polishing in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com