Rat-proof and anti-pressure prefabricated connection line

A connecting line and rodent-proof technology, which is applied in light guides, optics, instruments, etc., can solve problems such as low efficiency, damage to communication optical fibers, and rodent gnawing, and achieve the effects of easy installation and use, stable and reliable installation and use, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

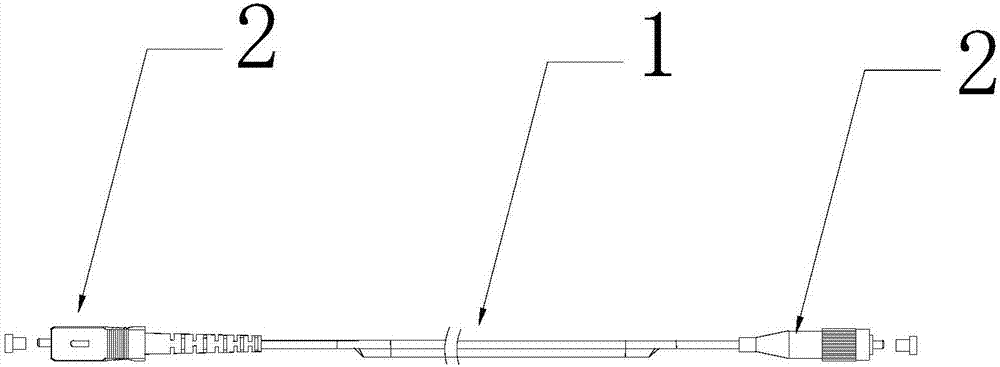

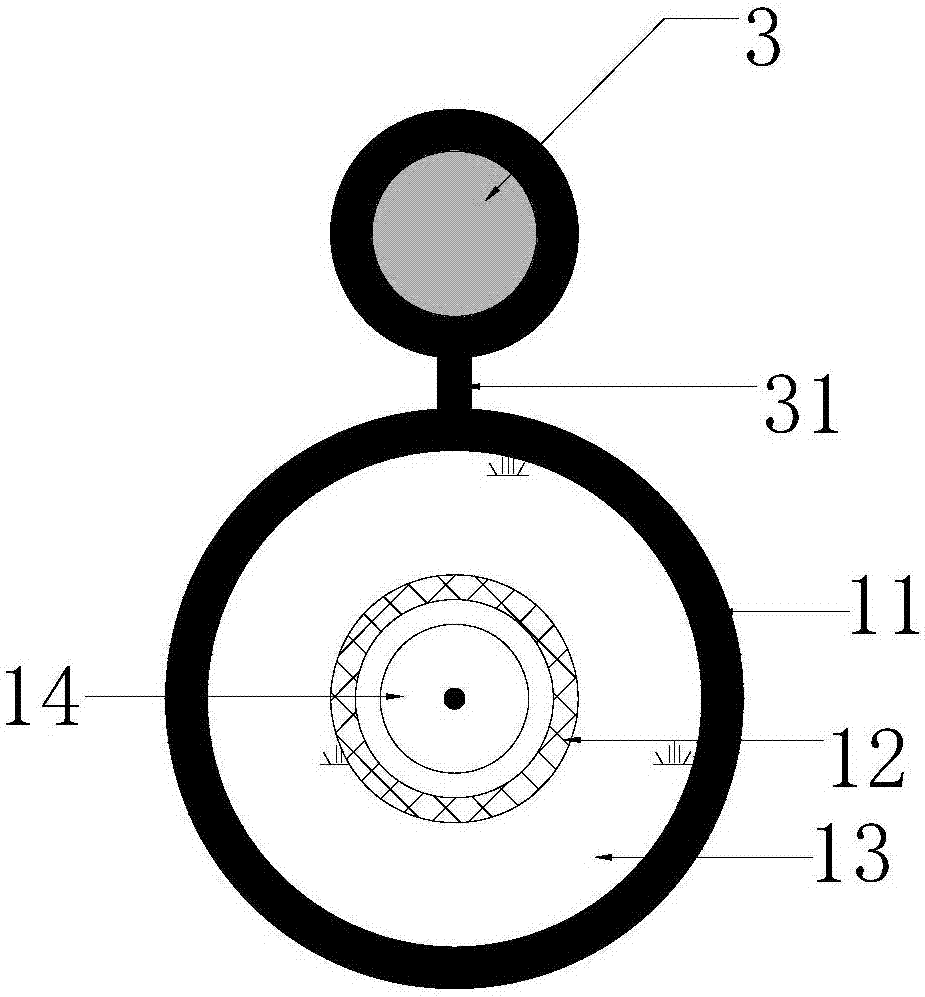

[0024] A kind of anti-rat and anti-pressure prefabricated connecting wire of this embodiment, such as figure 1 and figure 2 As shown, a rodent-proof anti-pressure prefabricated connecting line includes a rodent-proof and anti-pressure optical cable 1, a connector 2 connected to both ends of the rodent-proof and anti-pressure optical cable 1 and a reinforced suspension wire 3. The inside includes an outer sheath 11, a stainless steel armor tube 12 and a tight-sleeved optical fiber 13 in turn. The reinforced suspension wire 3 is connected to the rodent-proof and pressure-resistant optical cable 1 through a reinforcing rib 31. The reinforced suspension wire 3 is a thick steel wire suspension wire with a diameter of 1mm-1.2mm. The connectors 2 that need to be used during the installation process are pre-installed on both ends of the rodent-proof and pressure-resistant optical cable 1. When performing FTTH operations, professionals do not need to use special tools to operate, and ...

Embodiment 2

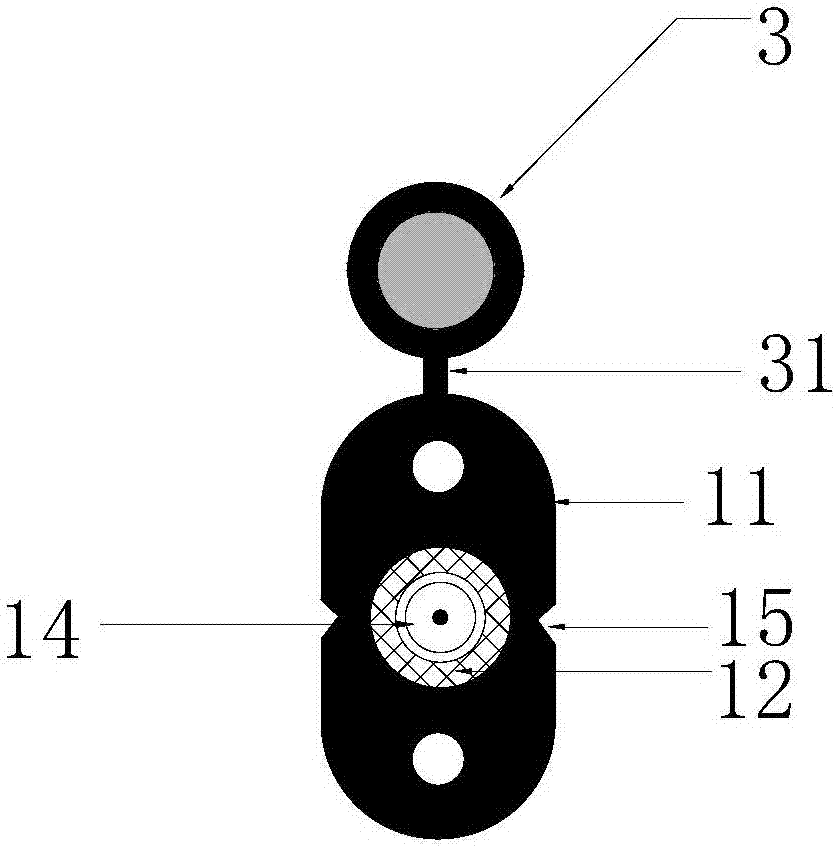

[0029] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the cross section of the outer sheath 11 is elliptical, and the surface of the outer sheath 11 is provided with a V-shaped groove 15 extending along the surface of the rat-proof and pressure-resistant optical cable 1. The type groove 15 divides the anti-rat and anti-pressure optical cable 1 into upper and lower parts. Although the outer sheath 11 of this structure is difficult to manufacture, its flattened oval cross-section is easier to pass through some buildings. flat hole, and due to the larger force-bearing area, can withstand greater extrusion force, solve the problem that the circular outer sheath 11 in embodiment 1 is easy to be damaged due to greater extrusion force; at the same time, The V-shaped groove 15 extending along the surface of the mouse-proof and pressure-resistant optical cable 1 makes it easier to clamp the mouse-proof and pressure-resistant prefabricated con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com