Analysis of mechanical properties of warp-knitted wire mesh based on finite element method

A technology of wire mesh and finite element method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of expensive materials, high economic costs, and low work efficiency, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

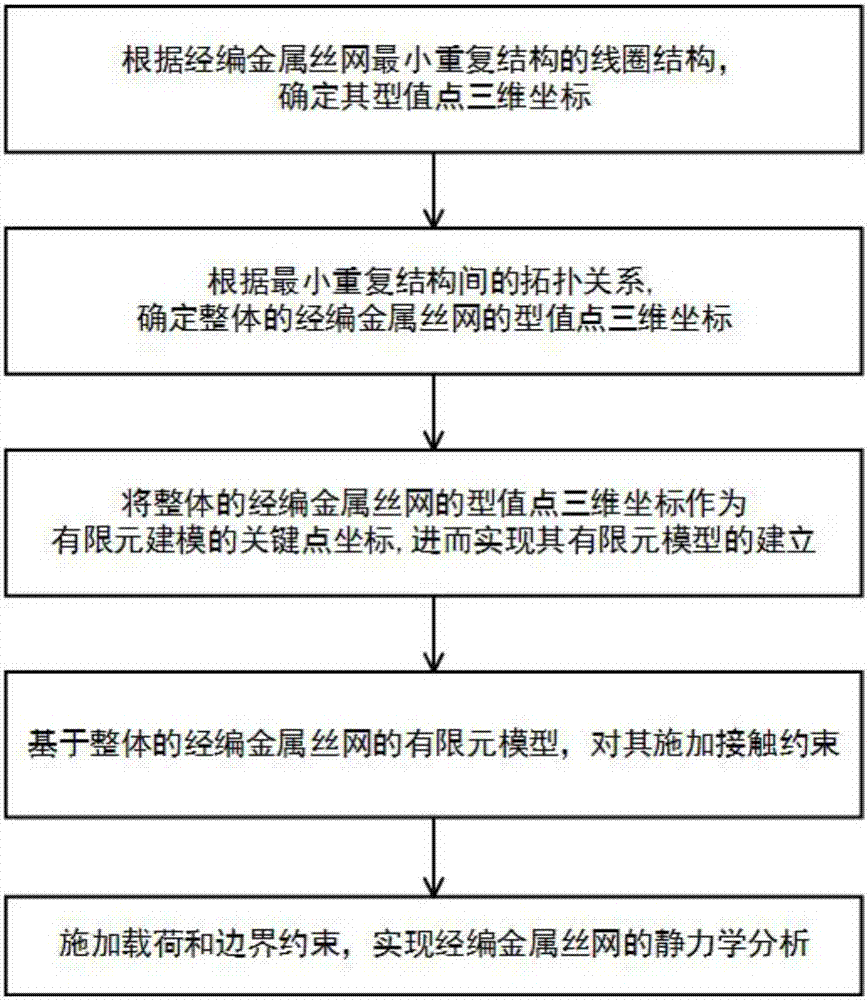

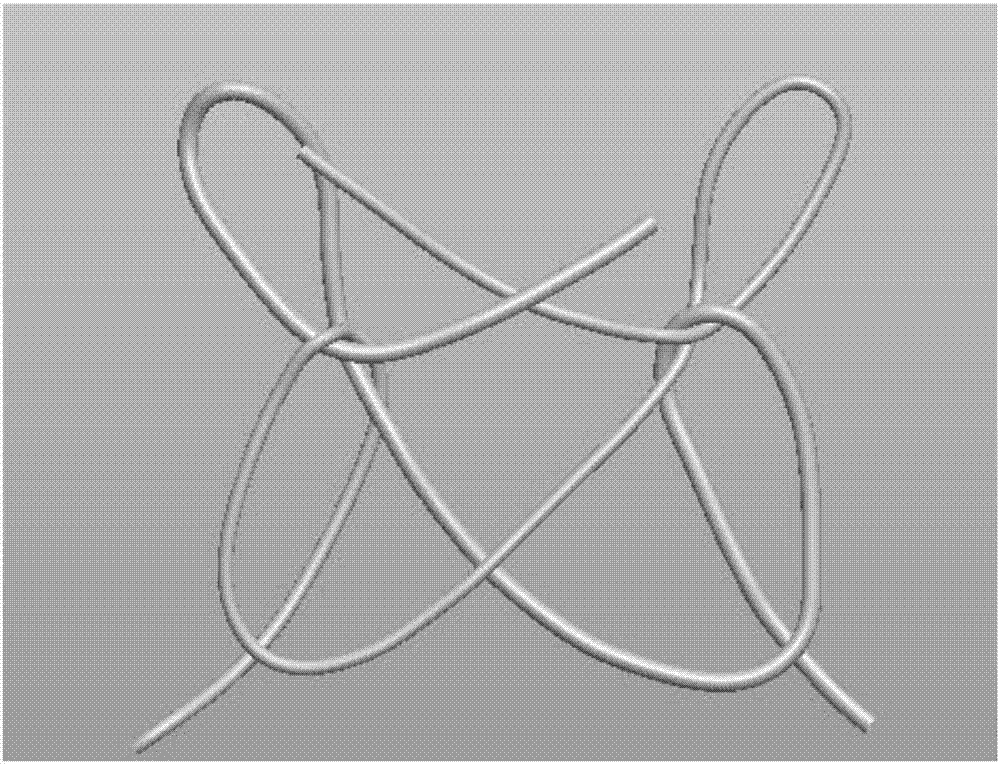

[0041]The invention discloses a warp-knitted wire mesh mechanical characteristic analysis based on the finite element method, which utilizes image data processing technology and finite element method to realize the finite element modeling and mechanical characteristic analysis of the wire mesh, and its flow chart is as follows figure 1 As shown, the detailed steps are as follows:

[0042] Step 1) obtain the three-dimensional coordinates of the minimum repetitive structure value point of the warp-knitted wire mesh, specifically comprising the following steps:

[0043] Step 1.1) Obtain a high-resolution photo of the warp-knitted wire mesh by photogrammetry;

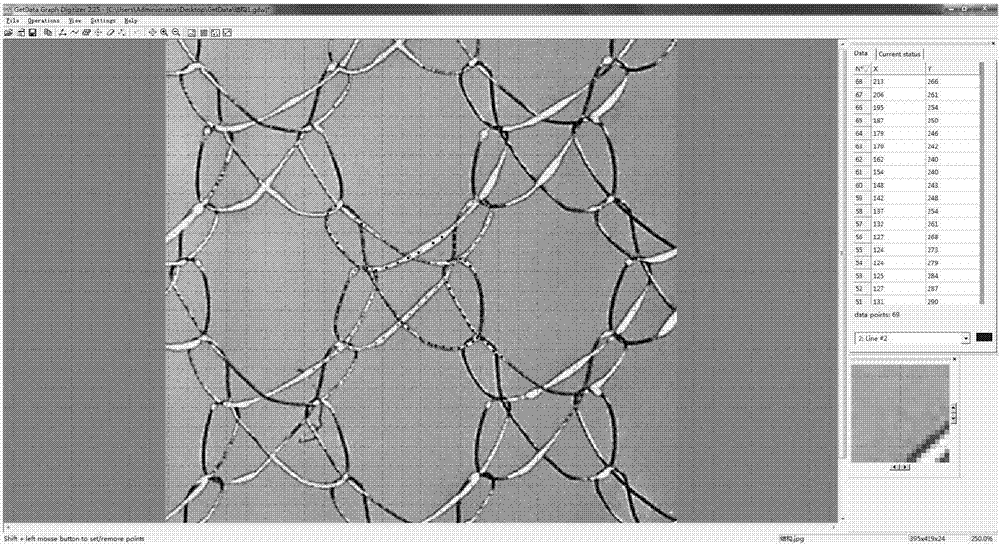

[0044] Step 1.2) Based on the current image data processing technology, the high-definition image of the warp-knitted wire mesh obtained in step 1.1) can be imported into the image processing software GetData Graph Digitizer, and the direction of its monofilament is outlined by the image processing software GetDataGraph Dig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com