Heat superconductive panel fin radiator with fins on surface thereof

A technology of thermal superconductivity and heat sink, applied in the field of heat transfer, can solve the problems that aluminum heat sinks cannot meet the heat dissipation requirements of high heat flux density and high-power modules, and achieve good work adaptability, solve heat dissipation requirements, and small volume effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

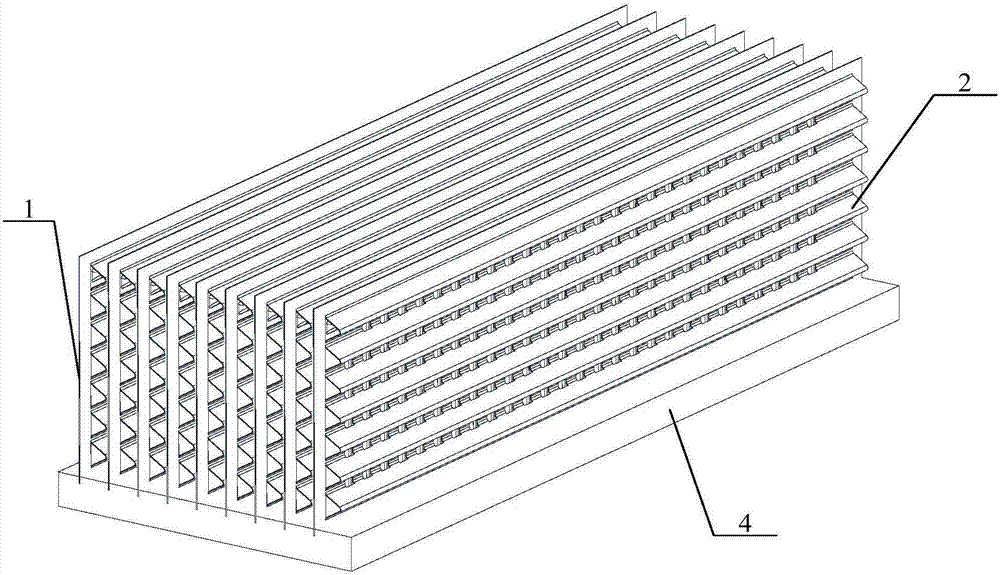

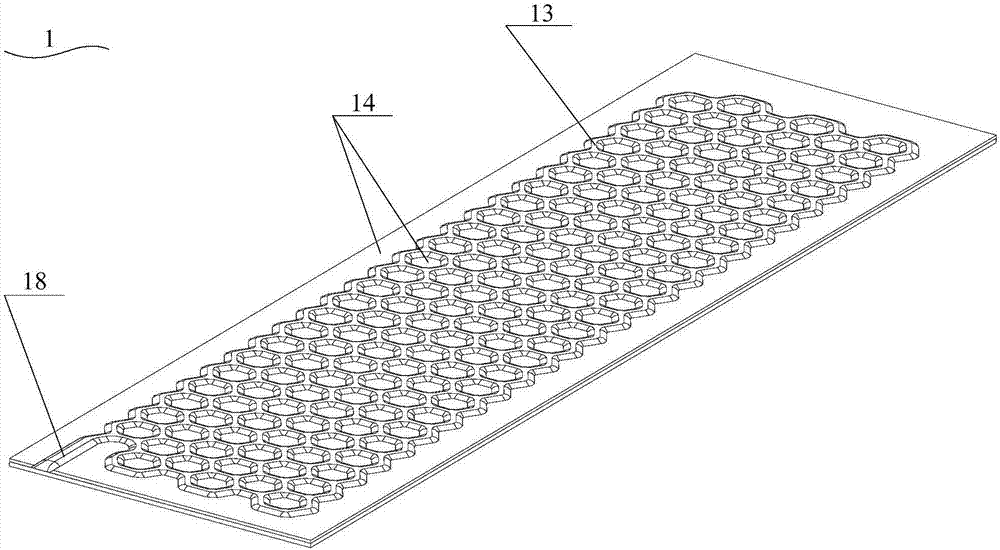

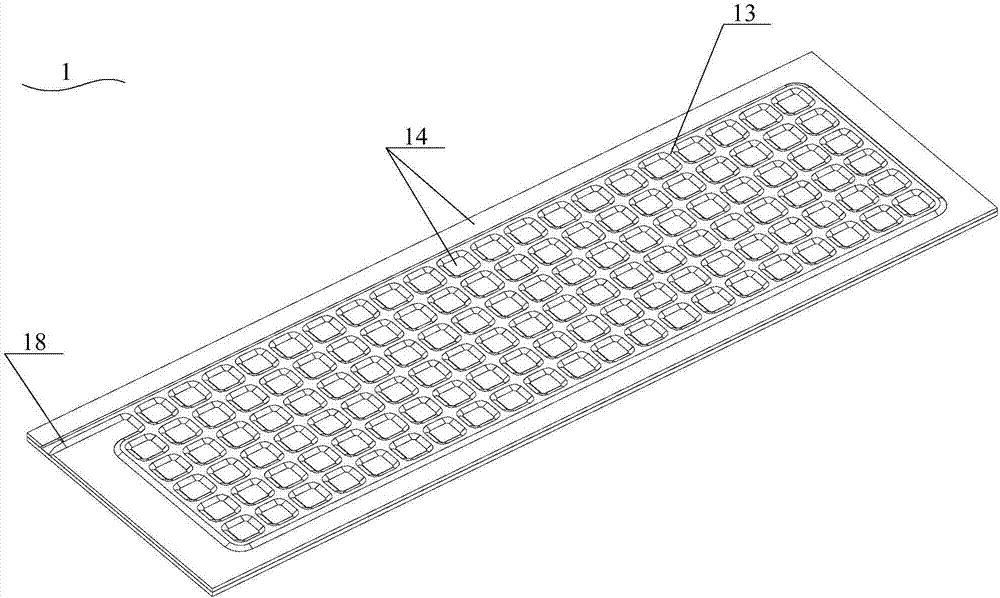

[0074] see Figure 1 to Figure 12 , the present invention provides a thermal superconducting plate-finned radiator with fins on the surface, the thermal superconducting plate-finned radiator with fins on the surface comprising: a radiator substrate 4; Conductive heat dissipation plate 1, a plurality of thermal superconducting heat dissipation plates 14 are inserted in parallel on the surface of the heat sink substrate; a thermal superconducting circuit 13 is formed in the thermal superconducting heat dissipation plate 1, and the thermal superconducting conduit The road 13 is a closed pipeline, and the thermal superconducting pipeline is filled with a heat transfer working medium (not shown); a heat dissipation fin structure 2, and the heat dissipation fin structure 2 is located at least on the thermal superconducting heat dissipation plate 1 One surface; the heat dissipation fin structure 2 includes at least one heat dissipation fin 21 extending in a wave shape in a direction ...

Embodiment 2

[0095] This embodiment also provides a thermal superconducting plate-finned heat sink with fins on the surface. The structure of the thermal superconducting component described in this embodiment is the same as that described in Embodiment 1. The structures of thermal superconducting plate-finned heat sinks are roughly the same, and the difference between the two is that in Embodiment 1, the heat dissipation fin structure 2 includes a first heat dissipation fin 22, and the first heat dissipation fin 22 is located at One surface of the thermal superconducting heat dissipation plate 1; and in this embodiment, the heat dissipation fin structure 2 includes two first heat dissipation fins 22, and the two first heat dissipation fins 22 are respectively located at the The two opposite surfaces of the thermal superconducting radiator plate 1.

Embodiment 3

[0097] see Figure 13 , this embodiment also provides a thermal superconducting plate-finned heat sink with fins on the surface, the structure of the thermal superconducting component described in this embodiment is the same as that described in Embodiment 1 that the surface is provided with fins The structure of the thermal superconducting plate finned heat sink is roughly the same, the difference between the two is: in the first embodiment, the heat dissipation fin structure 2 includes a first heat dissipation fin 22, and the first heat dissipation fin 22 Located on one surface of the thermal superconducting heat dissipation plate 1; and in this embodiment, the heat dissipation fin structure 2 includes a first heat dissipation fin 22, and the first heat dissipation fin 22 is located in two adjacent between the thermal superconducting heat sinks 1, and simultaneously fixed on the surfaces of two adjacent thermal superconducting heat sinks 1, that is, the first raised structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com