Thermal superconducting fin radiator and electrical equipment chassis

A thermal superconducting, finned technology, applied in electrical equipment structural parts, electrical components, cooling/ventilation/heating renovation, etc., can solve the problem of inability to meet the heat dissipation requirements of high heat flux density and high power modules, poor heat dissipation capacity, volume Large and other problems, to achieve the effect of good work adaptability, guaranteed heat dissipation capacity, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

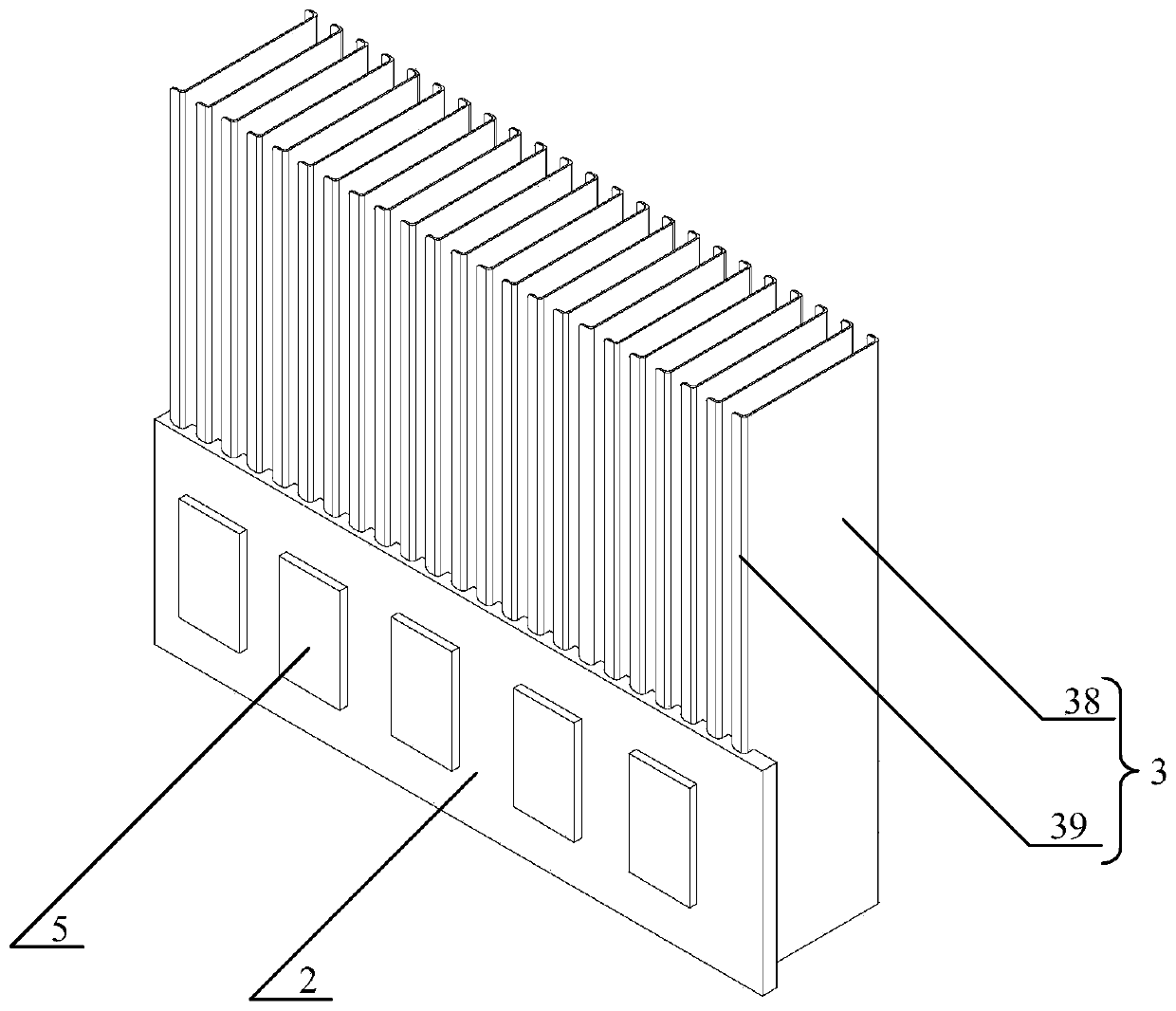

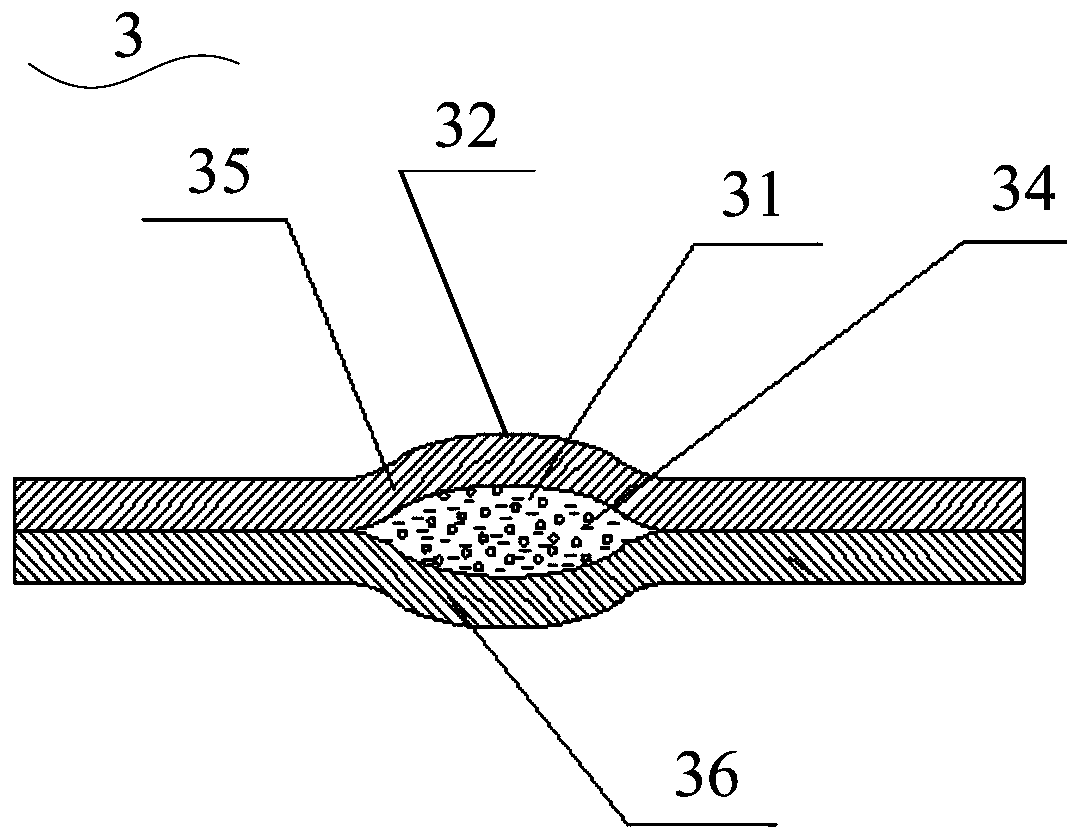

[0057] see Figures 2 to 6 , the present invention provides a thermal superconducting finned radiator, said thermal superconducting finned radiator comprising: radiator substrate 2; several thermal superconducting fins 3, said thermal superconducting fins 3 is inserted on the surface of the heat sink substrate 2; the thermal superconducting heat dissipation fin 3 is a composite plate structure, and a thermal superconducting circuit 31 of a specific shape is formed inside the thermal superconducting heat dissipation fin 3. The thermal superconducting pipeline 31 is a closed pipeline, and the thermal superconducting pipeline 31 is filled with a heat transfer working medium 34; the thermal superconducting fin 3 is a U-shaped plate structure, and the U-shaped plate structure includes Flat-shaped main body 38 and the bent side 39 compared with the flat-shaped main body 38; the projected area of several thermal superconducting cooling fins 3 in the plane where the heat sink substr...

Embodiment 2

[0069] see Figure 7 , the present invention also provides a thermal superconducting fin radiator, the structure of the thermal superconducting fin radiator described in this embodiment is the same as the structure of the thermal superconducting fin radiator described in Embodiment 1 Roughly the same, the difference between the two is: compared with the thermal superconducting fin radiator described in Embodiment 1, the thermal superconducting fin radiator in this embodiment has added a reinforcing buckle 4, so The reinforcement buckle 4 is at least located on one side of the thermal superconducting fins 3, and extends along the arrangement direction of the thermal superconducting fins 3, and is connected with each thermal superconducting fin 3 The sides are fixedly connected. in, Figure 7 Among them, the number of the reinforcing buckles 4 is five, and three of the reinforcing buckles 4 are located on the side of the thermal superconducting heat dissipation fin 3 away from...

Embodiment 3

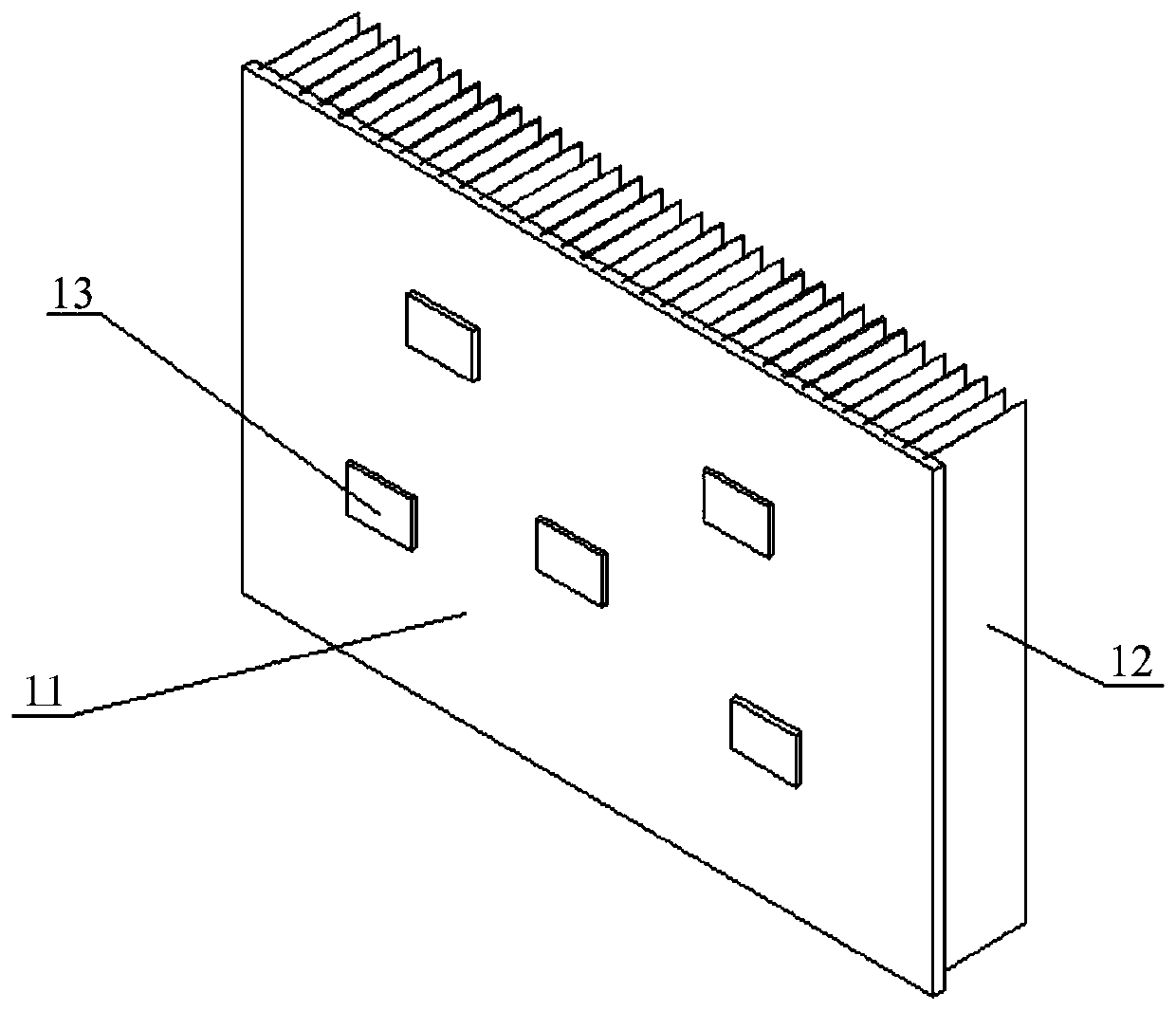

[0071]The present invention also provides an electrical equipment case, which includes: a main body of the case, the side or back of the main body of the case is provided with an opening communicating with the inside and outside; A finned heat sink, the thermal superconducting finned heat sink is fixed on the side of the chassis body where the opening is provided, and the heat sink substrate completely covers the opening; a power device, the power device is located The main body of the case is fixed on the surface of the radiator substrate away from the thermal superconducting fins.

[0072] To sum up, the present invention provides a thermal superconducting finned heat sink and an electrical equipment chassis. The thermal superconducting finned heat sink includes: a radiator substrate; several thermal superconducting fins inserted on the surface of the heat sink substrate; the thermal superconducting heat dissipation fin is a composite plate structure, and a thermal supercond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com