On-line charge-discharge control and capacity verification system and method of storage battery

A charge and discharge control and battery technology, applied in the field of DC systems, can solve the problems of inability to guarantee the safety of charge and discharge process, high cost of online discharge, and insufficient accuracy of capacity estimation, so as to realize online discharge check capacity, reduce workload, The effect of reducing the renovation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

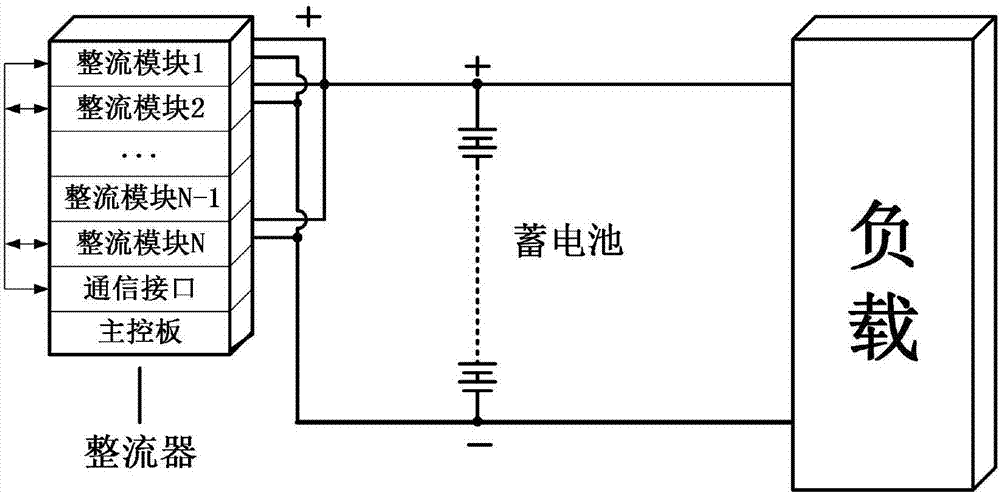

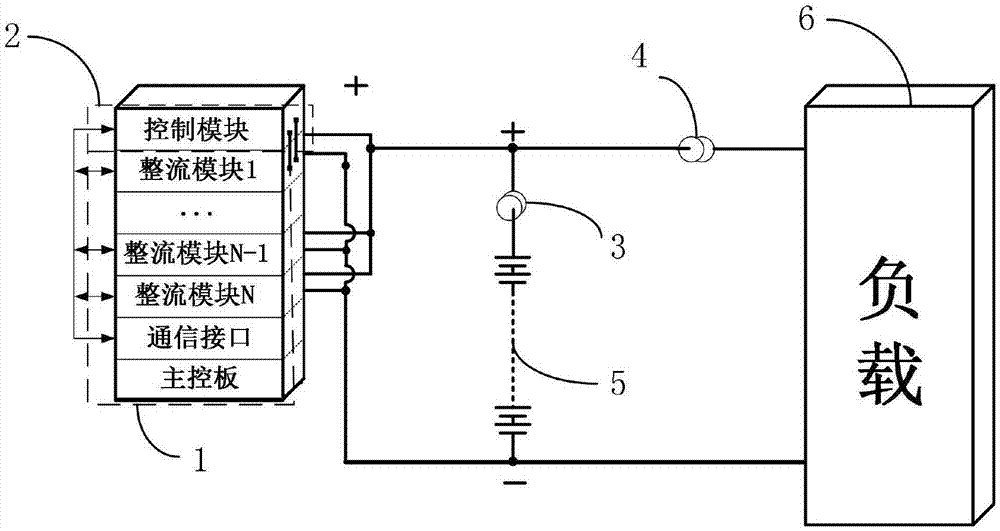

[0032] Embodiment one: see attached Figures 2 to 4 As shown, a storage battery online charge and discharge control and capacity checking system described in this embodiment includes a rectifier 1, a control module 2, a first transformer 3, a second transformer 4, a battery 5 and a load 6; the rectifier 1 includes N rectifier modules, communication interfaces and main control boards; the control module 2 includes a communication unit 2-2, an external current acquisition unit 2-3, and a CPU2-2 connected to the communication unit 2-2 and the external current acquisition unit 2-3, respectively. 1;

[0033] Wherein, the two ends of the load 6 are respectively connected with the two ends of the storage battery 5 to form a main circuit; the control module 2 is connected with the rectifier 1 through the communication unit 2-2, and is used to adjust the output voltage and output power of the rectifier 1, while the control module 2 and The rectifier 1 is connected in parallel with the...

Embodiment 2

[0039] Embodiment two: see attached figure 2 and Figure 5 As shown, it differs from Embodiment 1 in that the control module 2 includes a CPU2-1, an external current acquisition unit 2-3 connected to the CPU2-1, a PWM control circuit 2-4, and a connection between the PWM control circuit 2-4 and the CPU2- The driving circuit 2-5 of 1, the input voltage and current acquisition unit 2-6 connected to the CPU 2-1 for collecting the input voltage and current information of the control module 2, and the output voltage and current acquisition unit for collecting the output voltage and current information of the control module 2 2-7; The rectifier 1 and the control module 2 are connected in series to the DC bus, the output of the rectifier 1 is set in the battery floating charge state, and the constant current of the battery 5 is realized through the PWM control circuit of the control module and the closed-loop PWM control technology Discharge.

[0040] The specific control process ...

Embodiment 3

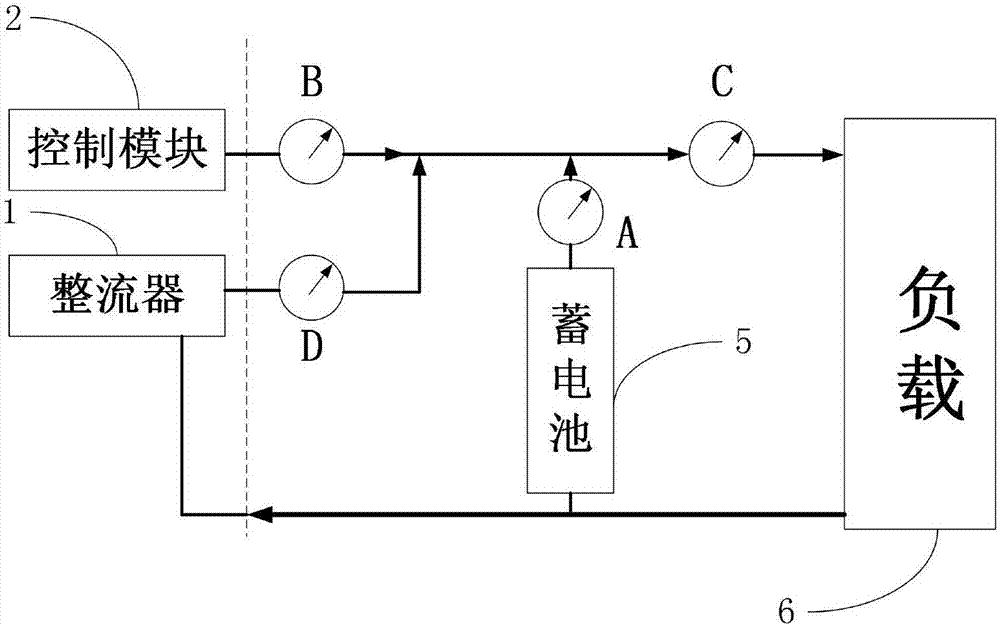

[0044] Embodiment three: see attached figure 2 and Figure 6 As shown, it differs from Embodiment 2 in that: the system also includes a single rectifier module 7; the single rectifier module 7 is connected in parallel with the rectifier 1 to the DC bus after being connected in series with the control module 2. During the discharge process, the current C of the load 6 is equal to the sum of the output current B of the control module 2, the output current D of the rectifier 1, and the discharge current A of the battery 5; during the charging process, the sum of the output current D of the rectifier 1 and the output current B of the control module 2 is equal to the sum of the output current B of the battery The sum of the charging current A and the load current C of 5.

[0045] The control module 2 makes the output voltage of the rectifier 1 slightly greater than the discharge cut-off voltage of the battery 5 through the communication unit 2-2, so that even if any abnormality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com