Control device based on photovoltaic maximum power point tracking

A technology of maximum power point and control equipment, applied in photovoltaic power generation, control/regulation system, and regulation of electrical variables, etc., can solve the problems of reduced tracking accuracy, failure to consider dynamic coupling, reduced tracking efficiency, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

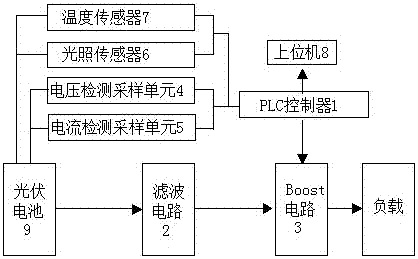

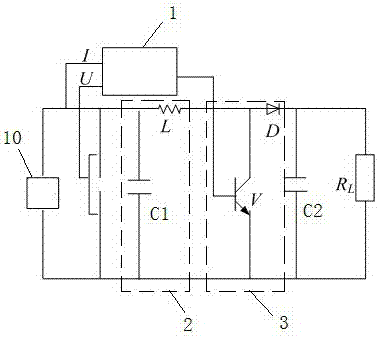

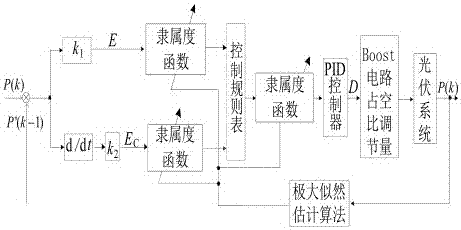

[0018] A control device based on photovoltaic maximum power point tracking, such as figure 1 As shown, it includes a sensor unit, a voltage detection sampling unit 4, a current detection sampling unit 5, a PLC controller 1 and an actuator, the actuator includes a Boost circuit 3 and a photovoltaic cell 9, and the photovoltaic cell 9 is connected to the Boost circuit 3 through a filter circuit 2, The Boost circuit 3 is connected in parallel with a load RL, the sensor unit includes a light sensor 6 and a temperature sensor 7, the light sensor 6 and the temperature sensor 7 are respectively arranged on the photovoltaic cell 9, and the light sensor 6 and the temperature sensor 7 are respectively connected to the input terminals of the PLC controller 1 , the output end of the PLC controller 1 is connected to the control end of the Boost circuit 3, and the input end of the PLC controller 1 is connected to the photovoltaic cell 9 through the voltage detection sampling unit 4 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com