Air filtering material

A technology of air filter material and lipophilic layer, applied in filtration and separation, membrane filter, coating and other directions, can solve the problems of reduced filtration accuracy, deformation of filter holes, difficult cleaning, etc., to reduce water loss and enhance water lock. Ability, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

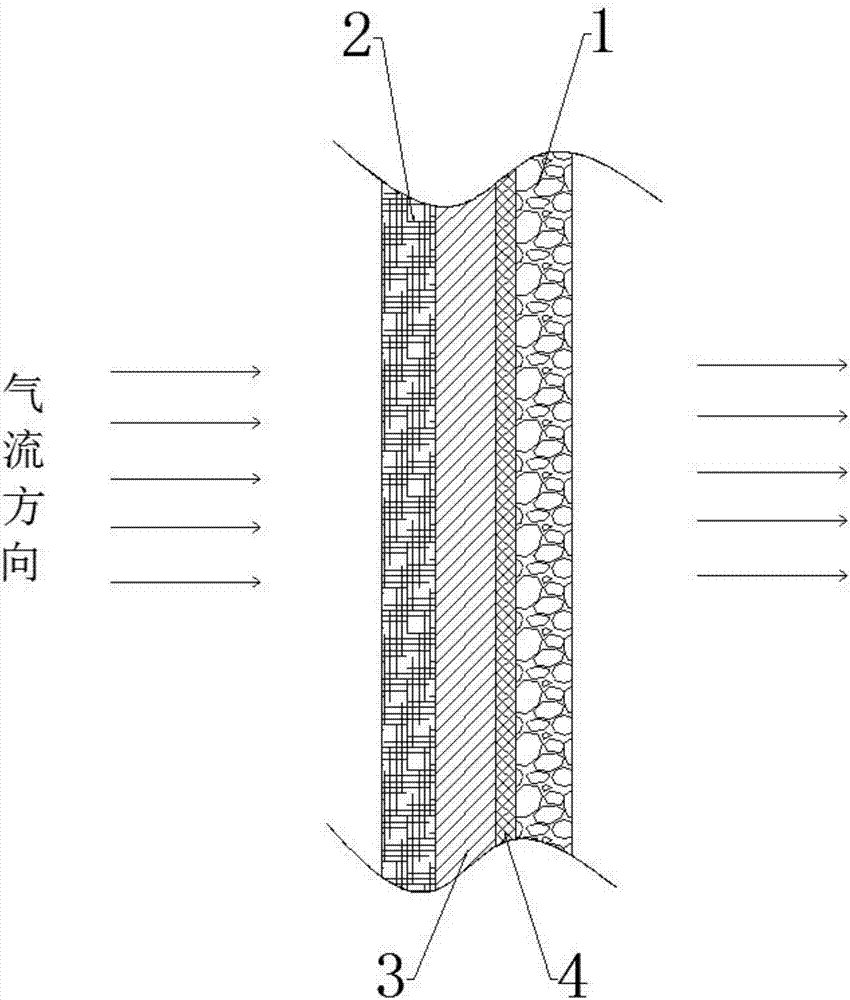

[0023] Hydrophobic layer 4 is made of polyester fiber and polypropylene fiber.

[0024] The lipophilic layer 2 is evenly and alternately woven from oil-absorbing yarns and oleophobic yarns, the ratio of oil-absorbing yarns to oleophobic yarns is 1:0.8, the oil-absorbing yarns are polypropylene yarns, and the oleophobic yarns are fluorinated polyacrylonitrile fiber yarns.

[0025] The hydrophilic layer 3 is evenly and alternately woven from water-absorbent yarns and hydrophobic yarns, the ratio of water-absorbent yarns to hydrophobic yarns is 1:1.1, the water-absorbent yarns are bamboo charcoal fiber yarns, and the hydrophobic yarns are treated with water- and oil-repellent finishing agents of polyester yarn.

Embodiment 2

[0027] The hydrophobic layer 4 is made of polypropylene fiber.

[0028] The oil-absorbing layer 2 is evenly and alternately woven from oil-absorbing yarns and oleophobic yarns, the ratio of oil-absorbing yarns to oleophobic yarns is 1:0.4, the oil-absorbing yarns are methacrylate yarns, and the oleophobic yarns are fluorinated polyurethane fiber yarns.

[0029] The hydrophilic layer 3 is evenly and alternately woven from water-absorbent yarns and hydrophobic yarns, the ratio of water-absorbent yarns to hydrophobic yarns is 1:1.6, the water-absorbent yarns are polyacrylonitrile fiber yarns, and the hydrophobic yarns are made of water- and oil-repellent finishing agents Treated polyester.

Embodiment 3

[0031] The hydrophobic layer 4 is made of spandex fiber, polyvinyl chloride fiber and acrylic fiber.

[0032] The oil-absorbing layer 2 is evenly and alternately woven from oil-absorbing yarns and oleophobic yarns, the ratio of oil-absorbing yarns to oleophobic yarns is 1:1.2, the oil-absorbing yarns are PVA modified cotton fiber yarns, and the oleophobic yarns are glass fiber yarns.

[0033] The hydrophilic layer 3 is evenly and alternately woven from water-absorbent yarns and hydrophobic yarns, the ratio of water-absorbent yarns to hydrophobic yarns is 1:2.5, the water-absorbent yarns are polyacrylate fiber yarns, and the hydrophobic yarns are made of water- and oil-repellent finishing agents Treated polyester yarn.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap