Drinking water bucket cleaning device

A cleaning device and drinking water technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low flushing efficiency, uneven flushing, high labor costs, etc., to achieve thorough cleaning and avoid stagnant water Excessive, high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

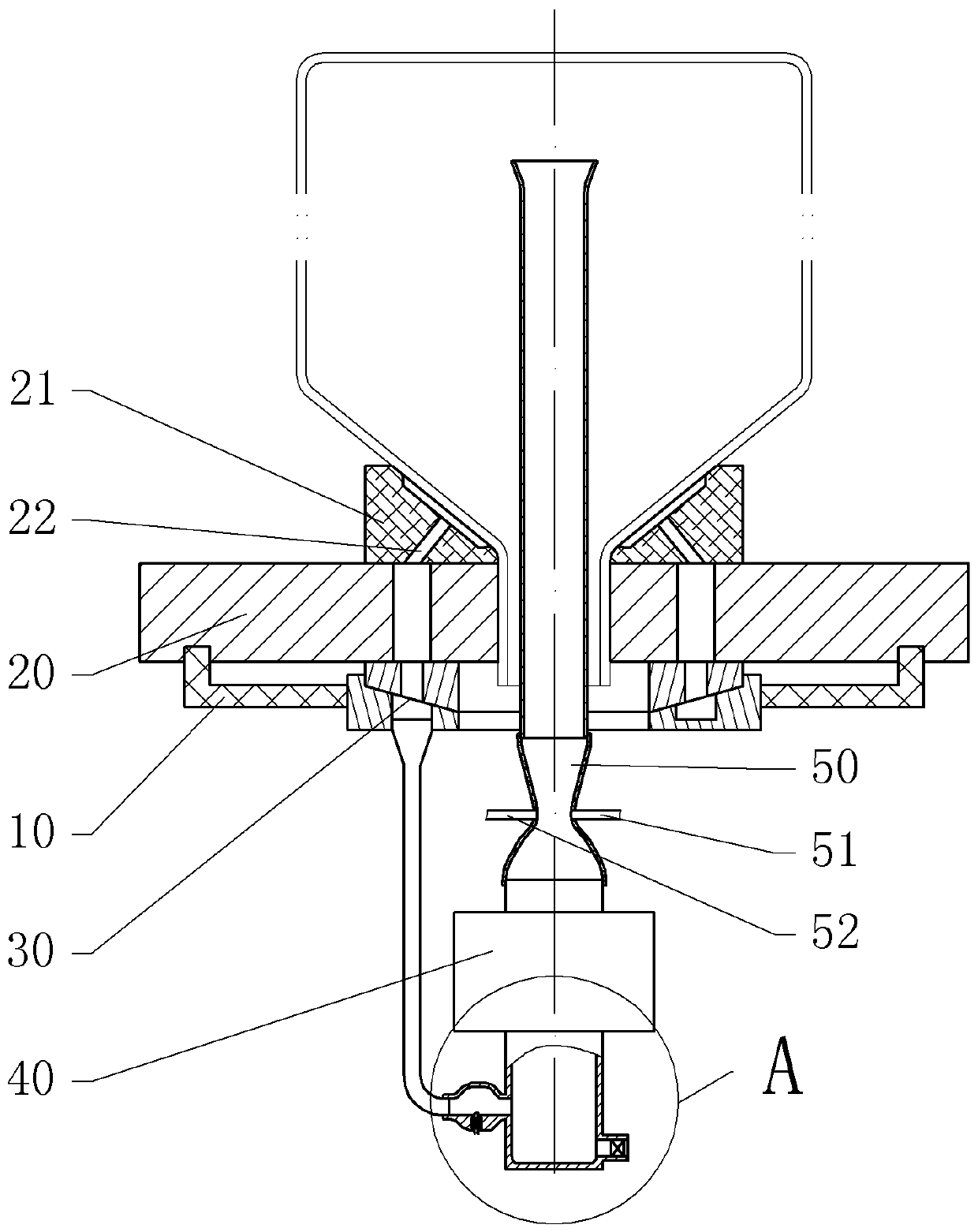

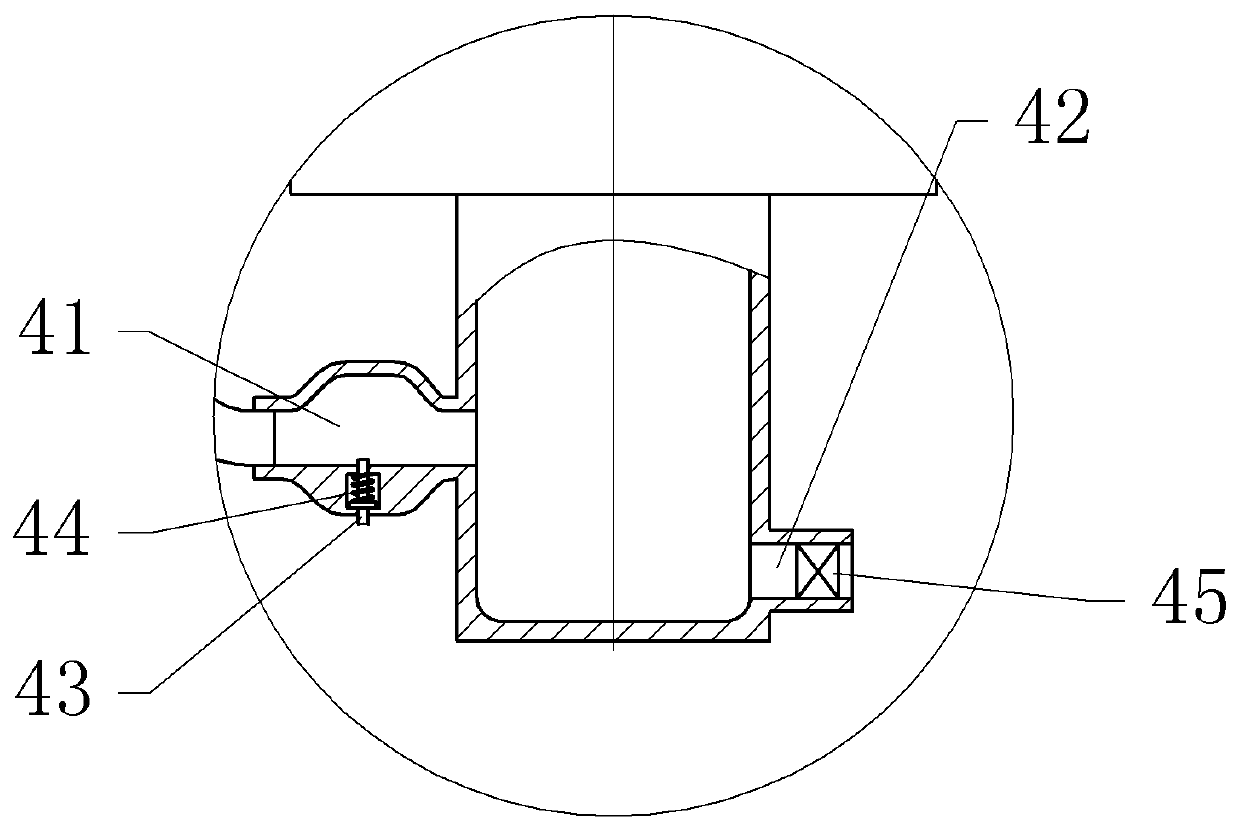

[0023] The reference signs in the accompanying drawings of the description include: seat body 10, turntable 20, suction cup 21, air hole 22, rotary joint 30, air pump 40, first air inlet 41, second air inlet 42, slide bar 43, return spring 44. Control valve 45, Venturi tube 50, particle spray pipe 51, water spray pipe 52.

[0024] The embodiment is basically as figure 1 , figure 2 Shown:

[0025] The drinking water bucket cleaning device of this embodiment includes a base body 10 , a motor and a turntable 20 rotatably connected to the base body 10 . The center of the turntable 20 is provided with a sleeve for the upper end of the water bucket to be inserted; the upper surface of the turntable 20 is fixed with a suction cup 21 that can cooperate with the water bucket, and the water bucket can be adsorbed on the turntable 20 through the suction cup 21, then the turntabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com