Rapid cooling and lubrication descaling guide system

A fast and guide roller technology, applied in the field of steel rolling, can solve the problems of good descaling effect and low degree of automation of guide roller cooling, and achieve the effects of improving efficiency, ensuring surface quality and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

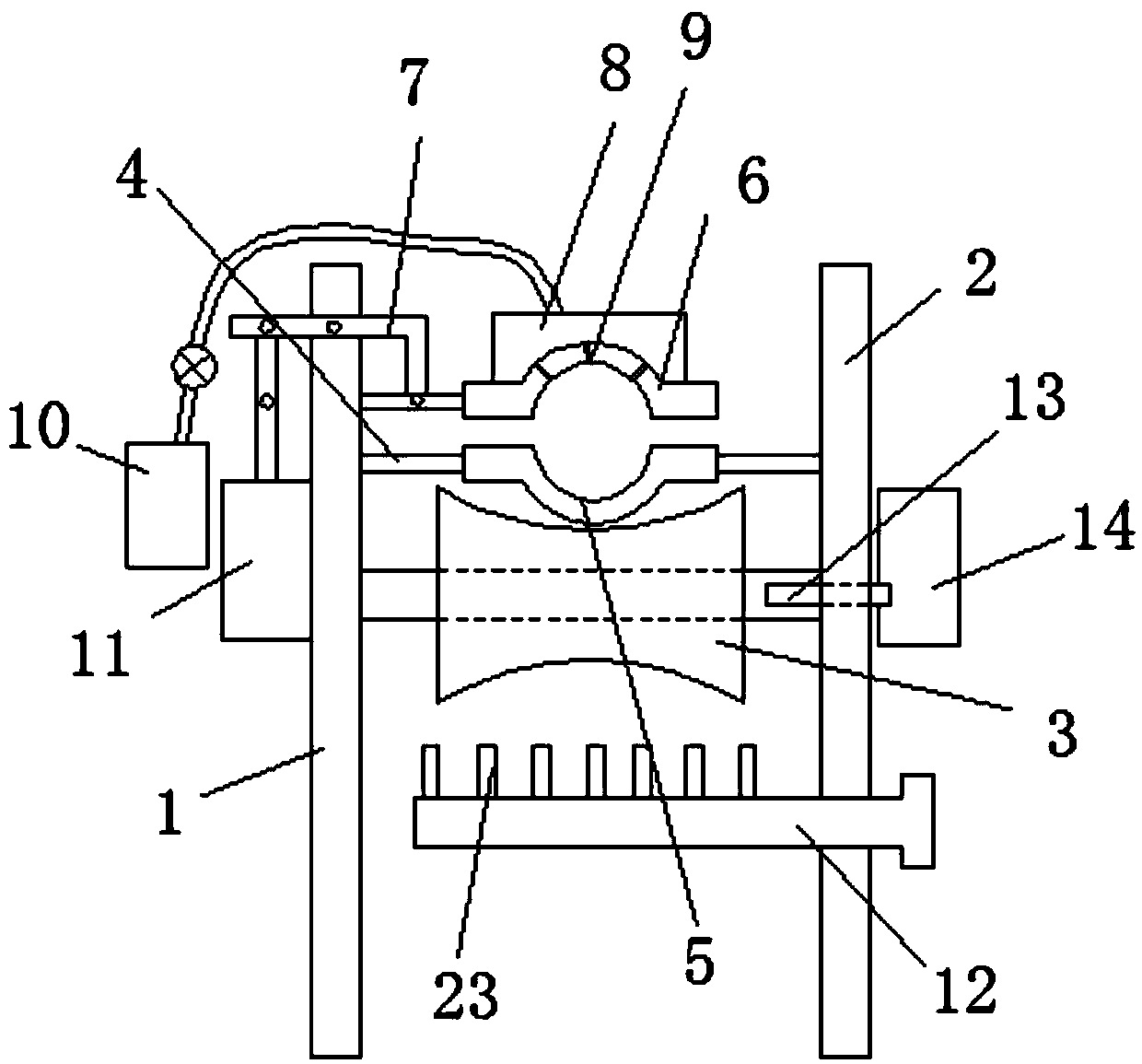

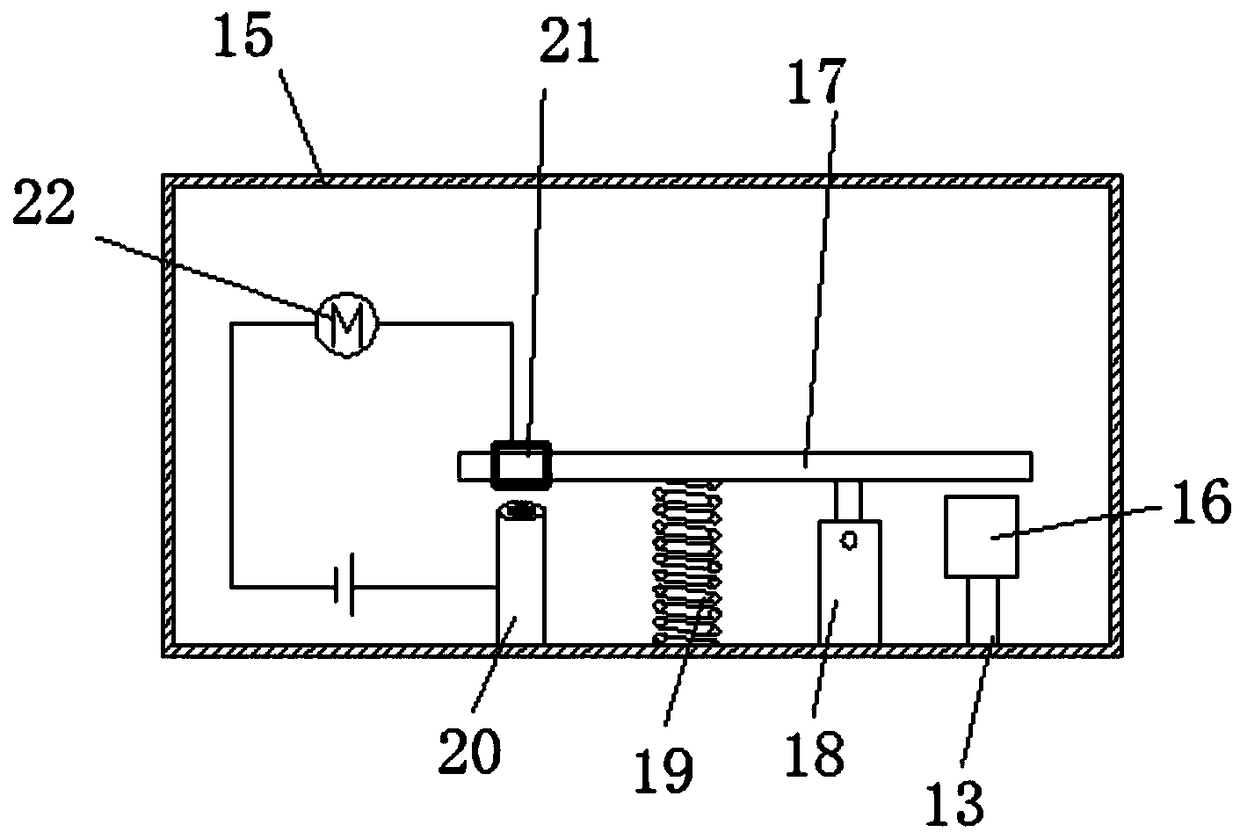

[0014] Referring to the accompanying drawings, a rapid cooling lubricating descaling guide system includes left and right two guide roller arms 1, 2, and a guide roller 3 is installed in rotation between the left and right two guide roller arms 1, 2. One side of the guide roller 3 is provided with a limit rod 4, and the central section of the limit rod 4 is provided with a lower descaling and dredging groove 5 for the wire, and an upper descaling and dredging groove 6 is provided above the lower descaling and dredging groove for the wire , the side wall of the upper descaling dredging groove 6 is connected to the cylinder 11 by a connecting rod 7, and the upper and lower opening and closing of the upper descaling dredging groove 6 can be realized through the adjustment of the cylinder. An oil storage tank 8 is arranged on the side wall, and the oil storage tank 8 communicates with the lubricating oil channel 9 on the inner wall of the upper descaling dredging tank, and the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com