Alternating current-direct current arc welding machine

An arc welding machine, AC and DC technology, used in arc welding equipment, welding equipment, welding accessories and other directions, can solve the problems of increasing the burnout of AC and DC arc welding machines, reducing the service life of AC and DC arc welding machines, and generating a lot of heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

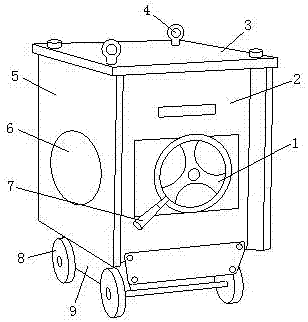

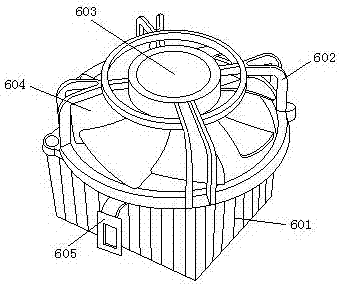

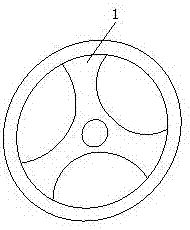

[0021] see Figure 1-Figure 3 , the present invention provides a technical solution: an AC / DC arc welding machine, the structure of which includes an adjustment wheel 1, a transformer 2, an upper cover 3, a lifting ring 4, a body 5, a rapid radiator 6, a handle 7, and a traveling wheel 8 , the base 9, the body 5 is composed of eight vertices and four curved surfaces, the curved surfaces are developed into a rectangle, the left and right end faces of the body 5 are parallel to each other, the upper and lower end faces of the body 5 are symmetrical to each other, the front of the body 5 is connected to the adjustment wheel 1 Interference fit mode is used for movable connection, the adjustment wheel 1 is connected with the handle 7, the inner cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com