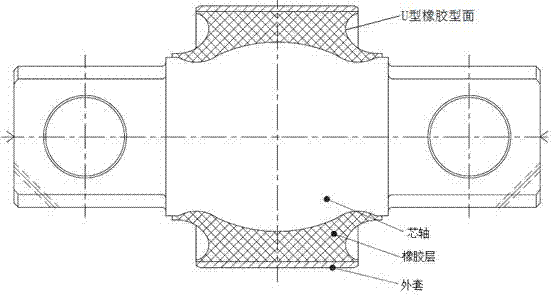

Design method for rubber profile of traction rod node and traction rod node

A technology of traction tie rod and design method, which is applied in railway car body parts, bogies, transportation and packaging, etc., can solve the problems of cracks or wrinkles, wrinkle cracking, and short fatigue life on the profile surface, so as to reduce wrinkles and cracks, The effect of reducing rubber bulge and improving deformation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

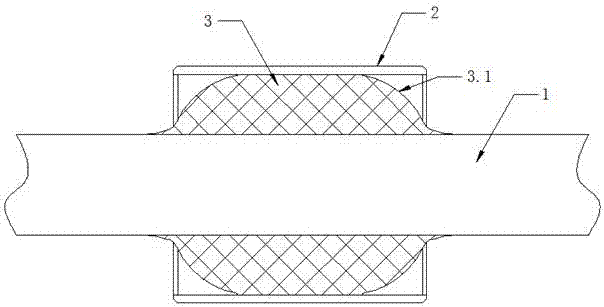

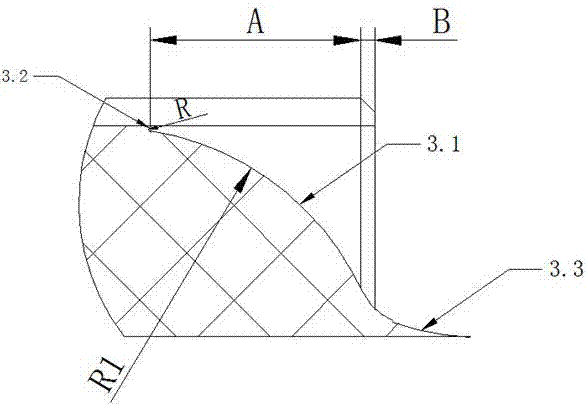

[0031] Attached below Figures 2 to 4 Embodiments of the present invention are described in detail.

[0032] The rubber profile design method of the traction rod node, including the mandrel 1, the outer shell 2 and the rubber layer 3 vulcanized and bonded between the mandrel 1 and the outer shell 2, is characterized in that the outer end profile of the rubber layer 3 is designed to The circular arc convex surface 3.1 protruding outward, the circular arc convex surface 3.1 gradually approaches the inner wall of the jacket 2 from the outside to the inside, and the arc convex surface 3.1 and the inner wall of the jacket 2 are transitioned through the transition surface 3.2, and the circular arc convex surface 3.1 and the core The outer walls of the shaft 1 are transitioned through the transition surface 2 3.3, the transition surface 3.2 is designed as an inwardly concave arc surface, and the transition surface 2 3.3 is designed as an inwardly concave arc surface.

[0033] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com