Arch-shaped roof

A vaulted roof, arched technology, applied to the vaulted roof. It can solve the problems of increasing processing procedures and increasing production costs, and achieve the effect of meeting diversified needs, simplifying production, processing and on-site assembly procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention discloses a vaulted roof. The specific implementation of the invention will be further described below in conjunction with preferred embodiments.

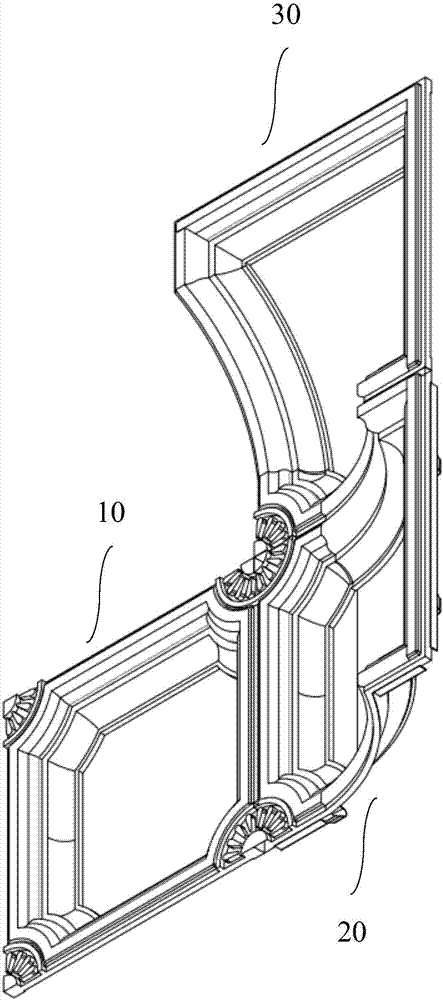

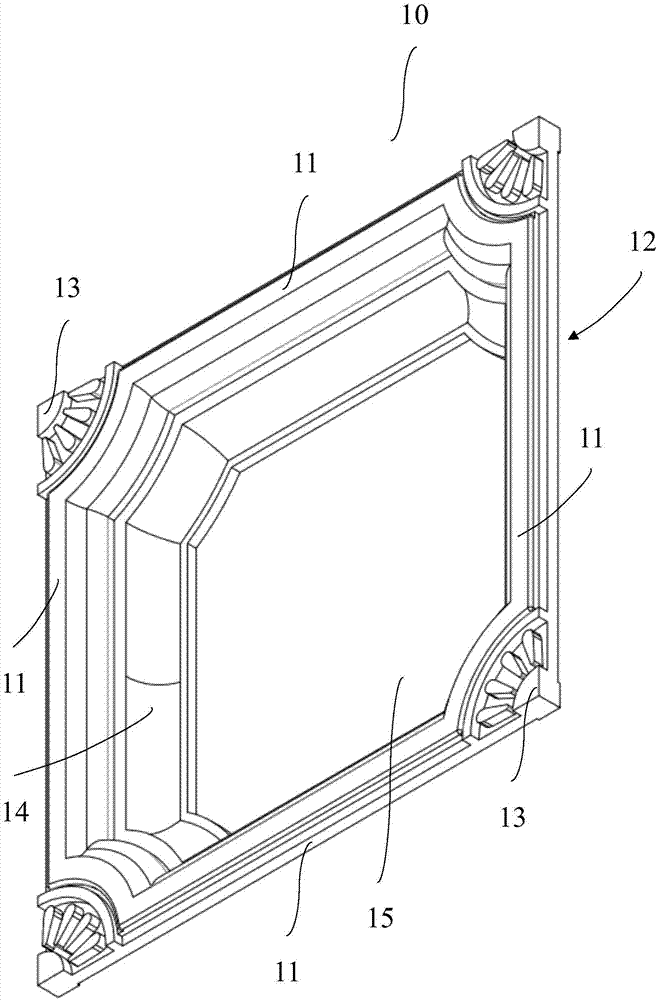

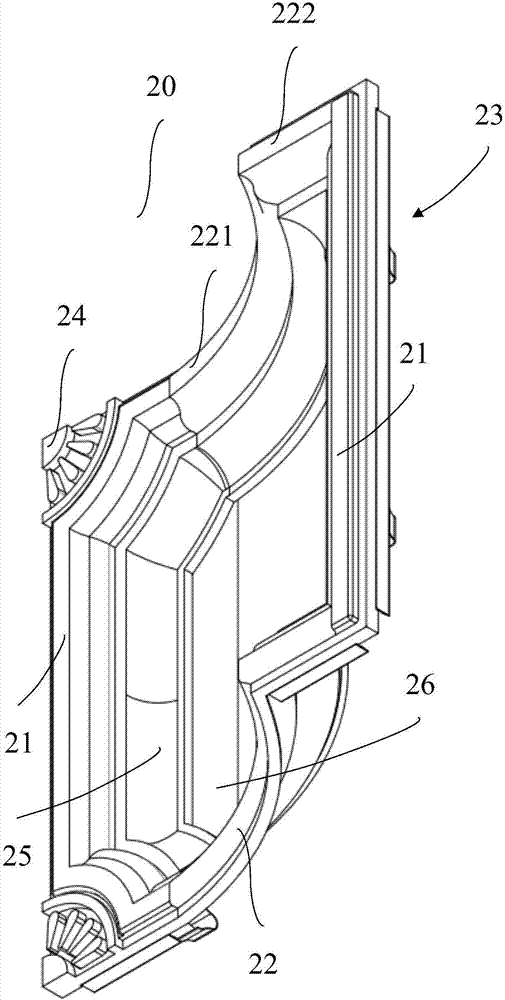

[0028] see attached figure 1 , figure 1 The overall structure of the dome is shown. Preferably, the arch top includes a first arch 10, a second arch 20 and a third arch 30, the first to third arches 10, 20, 30 are connected in pairs and Arrange and combine to form a module combination, and assemble according to the actual situation such as the ceiling area and shape to form a module combination.

[0029] see attached Figure 5A , Figure 5A It shows a modular combination (plan view) formed by combining the first to third arch pieces 10, 20, 30, the module combination consists of 1 first arch piece 10, 4 second arch pieces Part 20 and four third arched parts 30 are formed. Among them, the four side walls of the first arched piece 10 in the middle are connected to the four second arched pieces 20 respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com