Ten-thousand-ton heavy duty train driving simulation training system

A simulation training system and technology for heavy-duty trains, which are applied in the field of driving simulation training systems for 10,000-ton heavy-duty trains, can solve problems such as differences in real driving experience, single training methods, and unfavorable simulation teaching for students, so as to achieve a strong sense of immersion and improve training. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

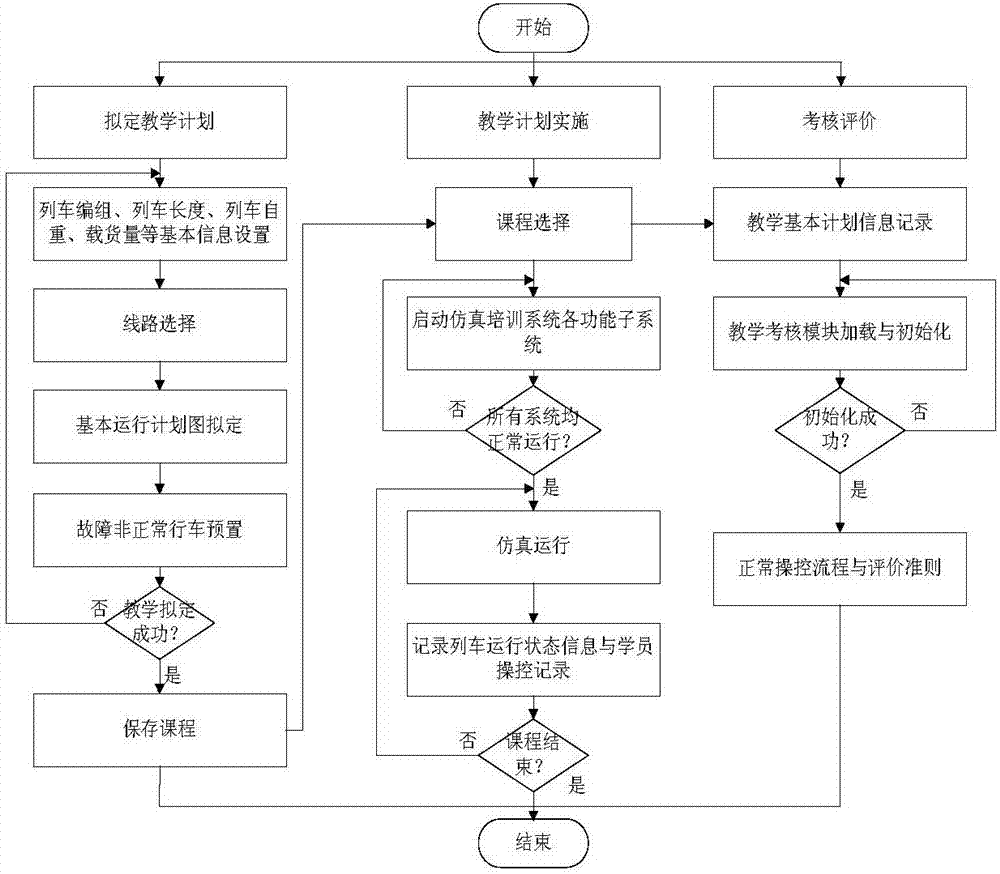

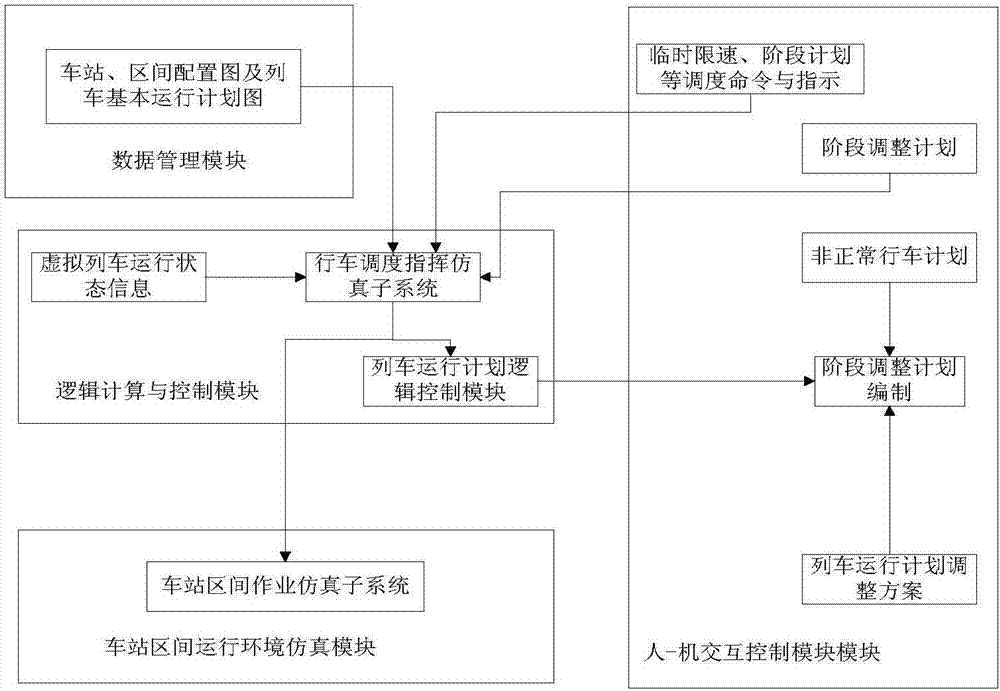

[0042] A 10,000-ton heavy-duty train driving simulation training system includes a train driving simulator, and the train driving simulator is created through the following steps:

[0043] A1. Carry out hardware replacement and software simulation equivalent for locomotive power components and equipment;

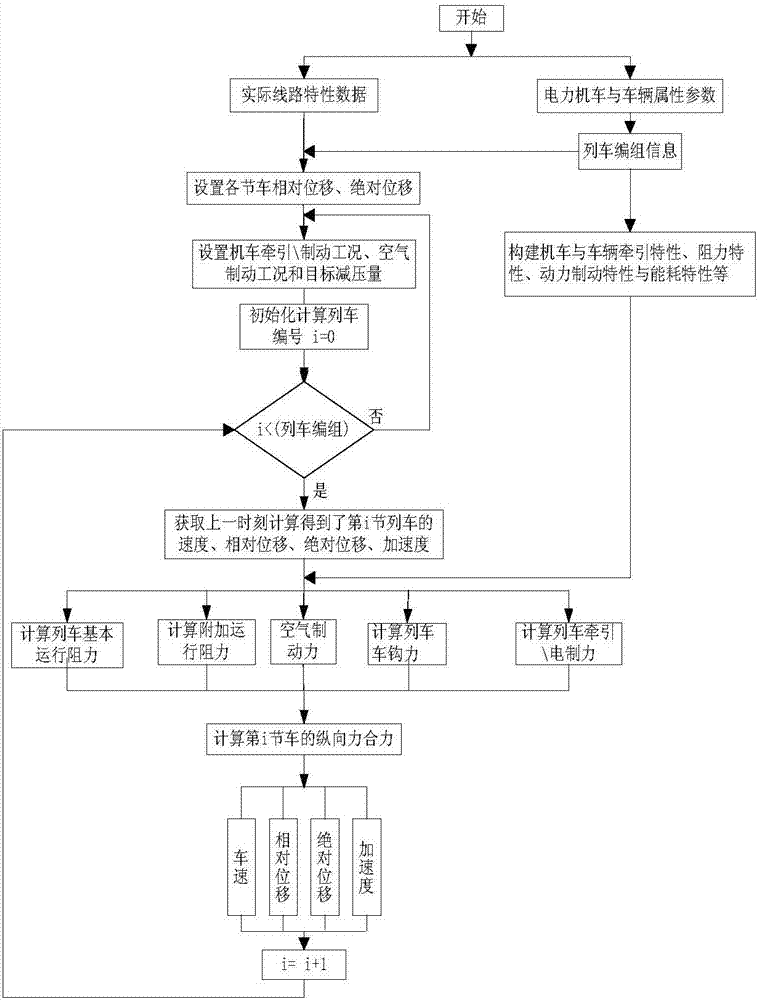

[0044] A2. According to the attribute parameters of electric locomotives and vehicles, the functional characteristics of different models under different working conditions of different operating lines are constructed, and the operating conditions of locomotives and vehicles under different operating conditions of different line sections are calculated in combination with the actual operating lines. The vehicle attributes Parameters include vehicle length, load, self-weight, coupler force between vehicles, and electrical characteristics of power components;

[0045] A3. Create a sound and picture system according to the running conditions of the locomotive in different opera...

Embodiment 2

[0049] According to the principle of Embodiment 1, this embodiment takes the SS4B and Shenhua electric locomotives with large actual operating load, high operating efficiency, good safety, advanced technology and mature technology as examples for simulation description.

[0050] A1. According to the actual hardware composition structure of SS4B and Shenhua electric locomotives on the railway site, simulate relevant power components and combine the real equipment circuit control schematic diagram of the locomotive to perform hardware replacement and software simulation equivalent for all power components of the locomotive.

[0051] A2. Construct the traction, resistance, Functional characteristics such as dynamic braking and energy consumption, combined with the number of sections of the train’s actual operating line, the speed limit of each section, the number of slopes, the slope and length of each slope, the name of each station, the first The mileage of the center of the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com